A kind of method adopting loop reactor to synthesize 4,4'-dihydroxybiphenyl

A dihydroxybiphenyl and loop reactor technology, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve environmental pollution, low reaction efficiency, and 4,4'-dihydroxybiphenyl yield Low-level problems, to achieve the effect of reducing energy consumption, improving efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

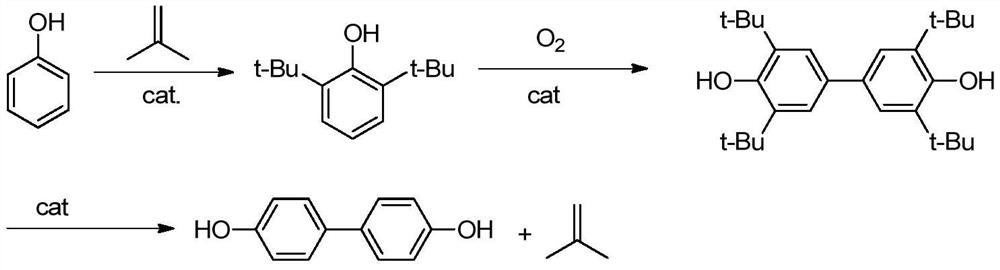

[0028] Specific embodiment one: In this embodiment, a method for synthesizing 4,4'-dihydroxybiphenyl using a loop reactor, the method includes the following steps:

[0029] 1. Add phenol to the reactor equipped with a loop reaction system;

[0030] 2. Introduce nitrogen for evacuation, add a Lewis acid catalyst, then introduce isobutylene, use a reactor equipped with a loop reaction system to react, control the temperature at 90-120°C, and react for 4-8 hours to obtain di-tert-butylphenol;

[0031] 3. Dissolve di-tert-butylphenol in an organic solvent, add an alkali catalyst and an oxidant in sequence, and use a reactor equipped with a loop reaction system for the reaction, control the temperature at 50-100°C, react for 2-4 hours, and then heat up to 180-100°C 200°C, react for 3 to 5 hours, then cool down and filter to obtain tetra-tert-butylbiphenol;

[0032] 4. Dissolve tetra-tert-butylbiphenyldiphenol in a mixed solvent, add a strong acid catalyst, control the temperature ...

specific Embodiment approach 2

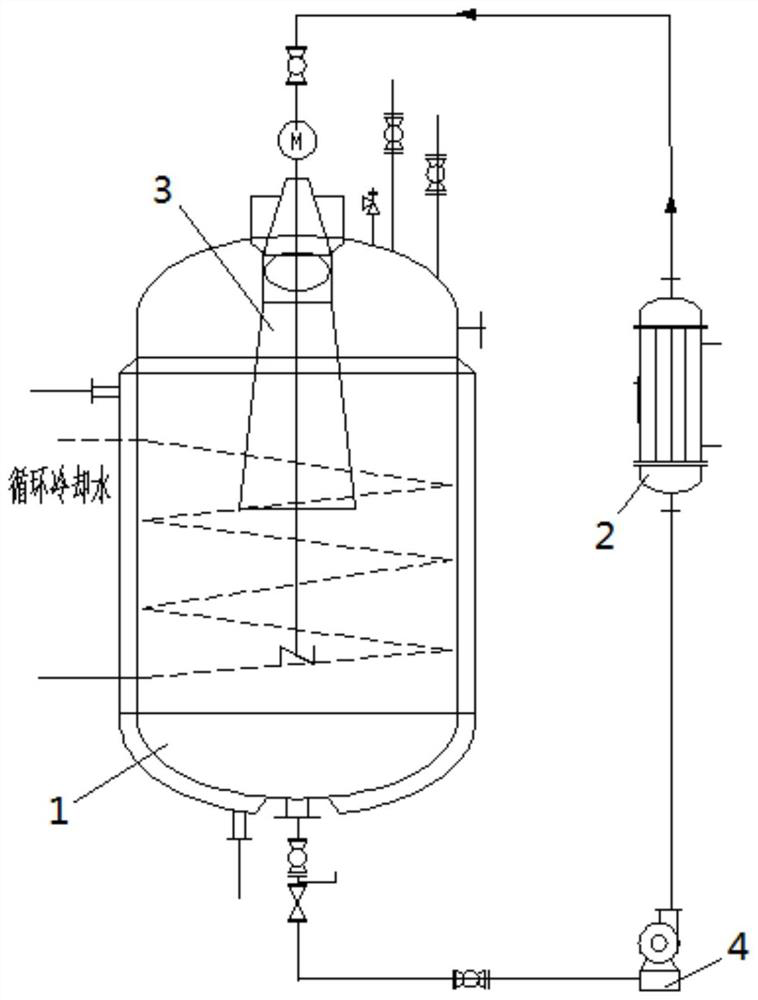

[0036] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the reaction kettle of the configuration loop reaction system described in step one includes reactor 1 and loop reaction system, and loop reaction system includes Venturi ejector 3, loop circulation pump 4 and heat exchanger 2; Venturi ejector 3 is arranged on the top of reactor 1, the inlet of Venturi ejector 3 communicates with the outlet of heat exchanger 2, the outlet at the bottom of reactor 1 communicates with the inlet at the bottom of heat exchanger 2, And a loop circulation pump 4 is arranged on the pipeline in which the outlet at the bottom of the reactor 1 communicates with the inlet at the bottom of the heat exchanger 2 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the Lewis acid catalyst described in step two is one of ferric chloride, aluminum chloride, zinc chloride, isopropyl aluminum and phenyl aluminum One or more kinds are mixed, and the dosage of the Lewis acid catalyst is 0.1% to 10% of the mass of phenol. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com