Retrievable hazardous waste rigid landfill system and operation method

A hazardous waste and rigid technology, applied in the removal of solid waste, underwater structures, water conservancy projects, etc., can solve problems such as failure to meet design requirements, facilitate automatic stacking operations, reduce leakage risks, and reduce workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated and explained below in conjunction with the accompanying drawings and specific examples. The various techniques in the present invention can be combined without mutual conflicts.

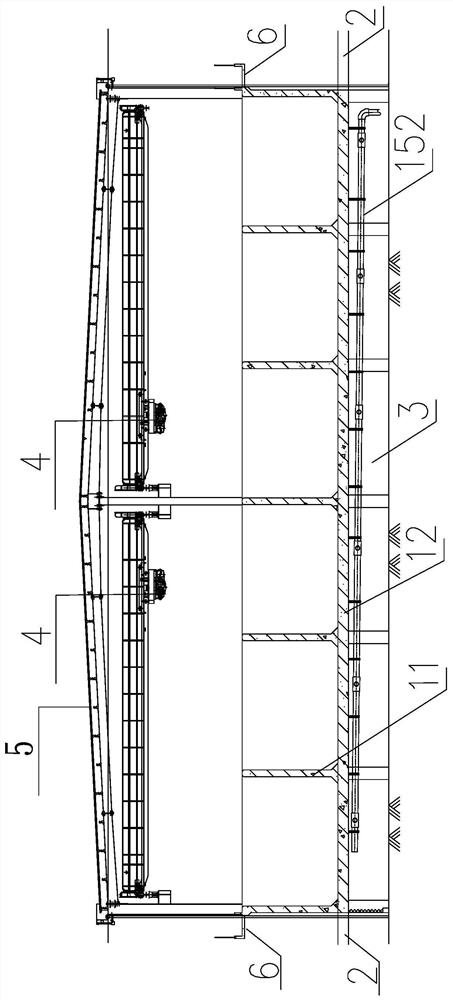

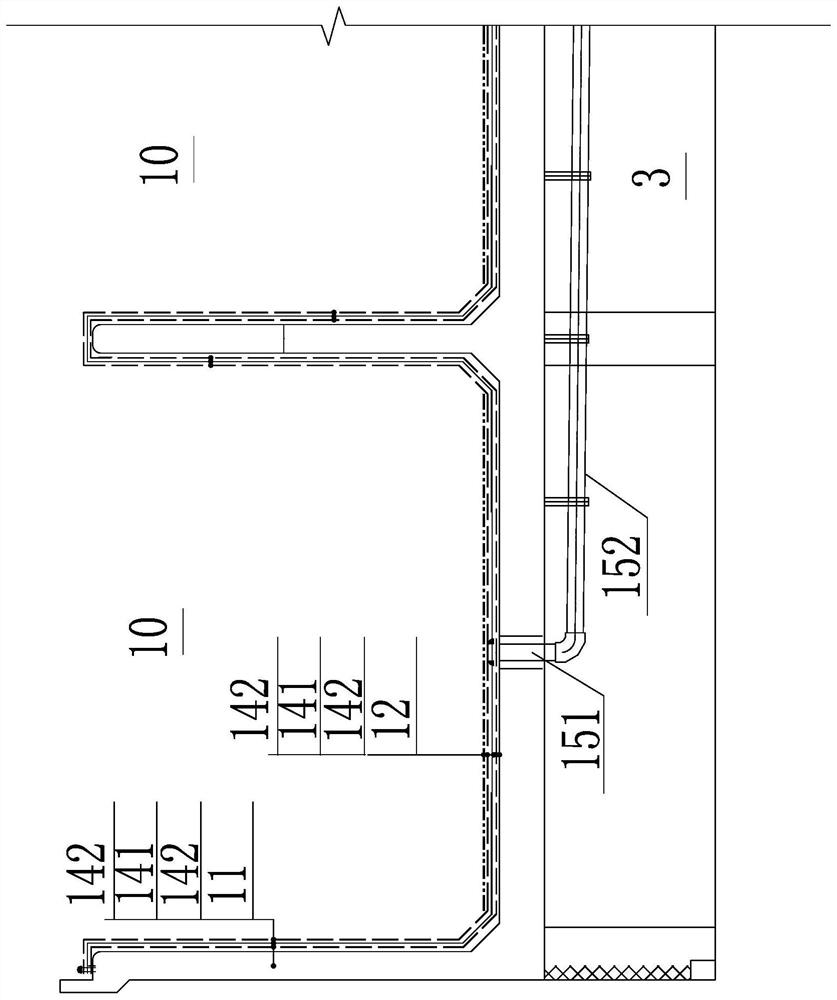

[0030] Referring to the drawings. The retired hazardous waste rigid landfill system provided by the present invention includes a hazardous waste landing reservoir region 1, a discharge passage 2, an overhaul interlayer 3, a door crane 4, a steel structure, and a person operation walkway 6.

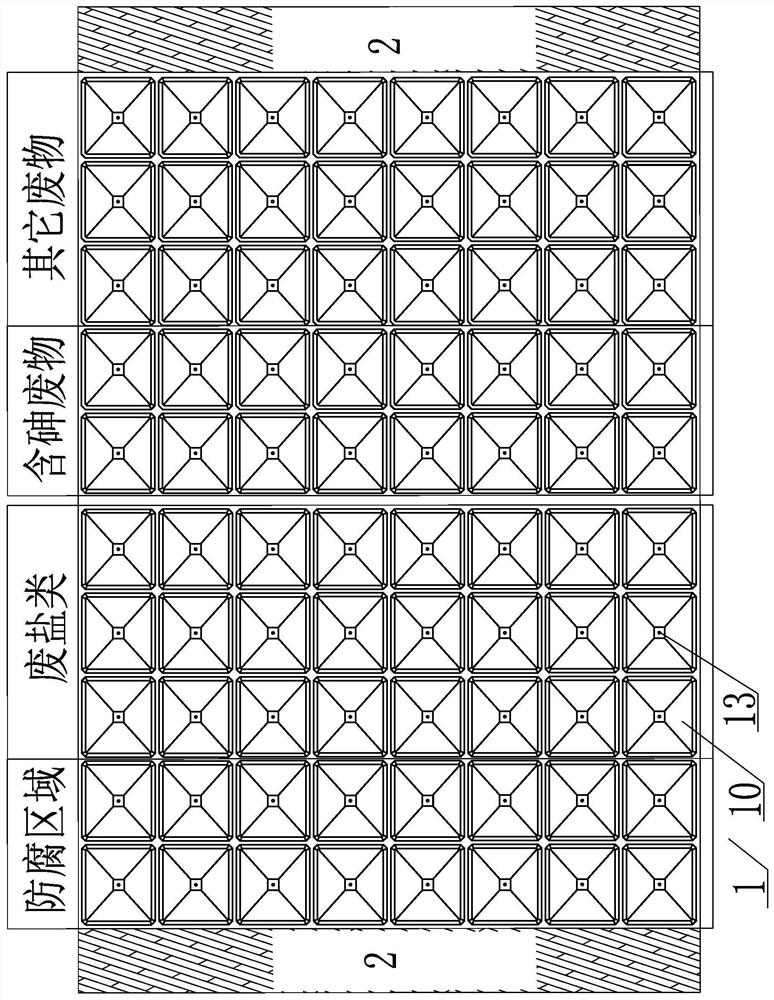

[0031] The hazardous waste landfill area 1 is made over the maintenance interlayer 3, which is composed of several landfill units 10, and the hazardous waste landing reservoir zone 1 is divided into regional division according to the characteristics of hazardous waste. Each area contains one or more landfill units, and the landfill unit is preferably set in a matrix, not only facilitates the construction building, but also facilitates management and door cranes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com