Energy-storage self-luminous epoxy resin mixture for road, preparation method and application

A light epoxy resin, epoxy resin technology, applied in the direction of roads, roads, buildings, etc., can solve the problems of easy aging, coating peeling, reduced luminous performance, etc., and achieve high temperature rutting resistance, good viscosity and flow. The effect of strong resistance and low temperature deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

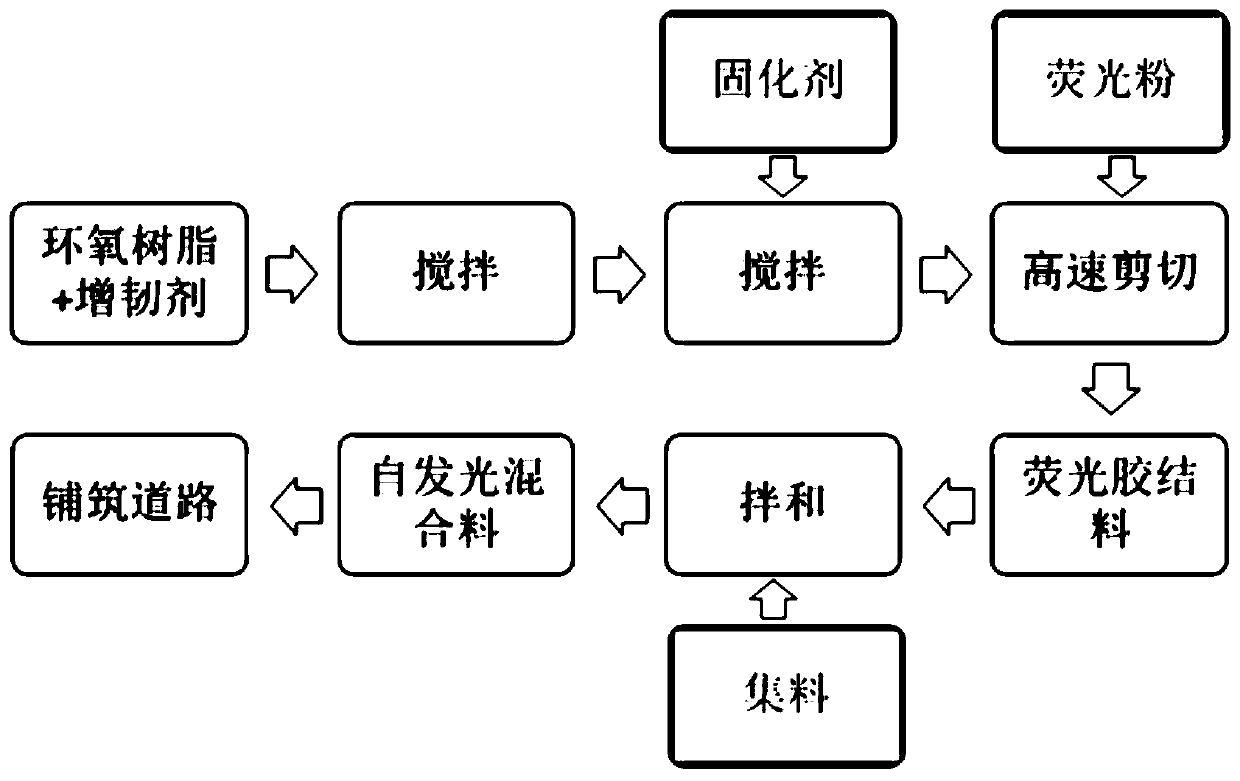

[0041] A method for preparing road-use energy-storage self-luminous epoxy resin mixture of the present invention comprises the following steps:

[0042] Step 1: Coarse aggregate (nominal particle size is greater than 2.36mm), fine aggregate (nominal particle size is 0.15mm-2.36mm) and fluorescent powder (nominal particle size is less than 0.15mm) according to the current specification "Technical Specifications for Construction of Highway Asphalt Pavement" "(JTG F40-2004) for gradation design;

[0043] Step 2: Take epoxy resin and toughening agent by weight percentage according to the design gradation, the dosage of toughening agent is 0.4%-1.0% of the total mass of coarse aggregate and fine aggregate, and the dosage of epoxy resin is coarse aggregate 6.0%-10.0% of the total mass of raw materials and fine aggregates. Add the toughening agent to the epoxy resin. Keep stirring continuously during the adding process. Stir with a stirrer. During stirring, the temperature is kept at...

Embodiment 1

[0049] A preparation method for road-use energy storage self-luminous epoxy resin mixture, comprising the following steps:

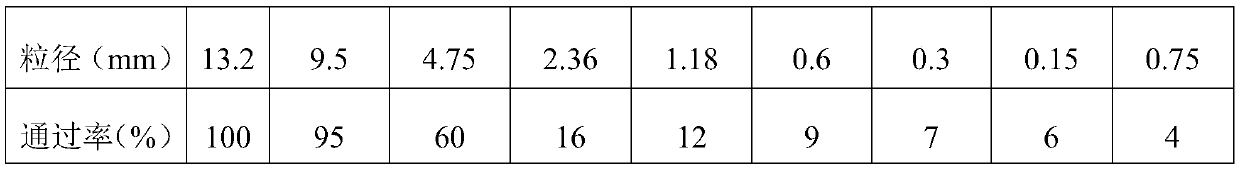

[0050] Step 1: Coarse aggregate (nominal particle size is greater than 2.36mm), fine aggregate (nominal particle size is 0.15mm-2.36mm) and fluorescent powder (nominal particle size is less than 0.15mm) according to the current specification "Technical Specifications for Construction of Highway Asphalt Pavement" "(JTG F40-2004) for gradation design, the gradation design is shown in Table 1.

[0051] Table 1

[0052]

[0053]

[0054] Step 2: design gradation according to Table 1 and take epoxy resin and toughening agent by weight percentage, the dosage of toughening agent is 0.4% of the total mass of coarse aggregate and fine aggregate, and the dosage of epoxy resin is coarse aggregate and 7.0% of the total mass of the fine aggregate, add the toughening agent to the epoxy resin, keep stirring continuously during the adding process, and stir throug...

Embodiment 2

[0060] A preparation method for road-use energy storage self-luminous epoxy resin mixture, comprising the following steps:

[0061] Step 1: Coarse aggregate (nominal particle size is greater than 2.36mm), fine aggregate (nominal particle size is 0.15mm-2.36mm) and fluorescent powder (nominal particle size is less than 0.15mm) according to the current specification "Technical Specifications for Construction of Highway Asphalt Pavement" "(JTG F40-2004) for gradation design, the gradation design is shown in Table 2.

[0062] Table 2

[0063] Particle size (mm) 13.2 9.5 4.75 2.36 1.18 0.6 0.3 0.15 0.75 Passing rate(%) 100 95 60 44 32 23 14 8 5 Mass ratio (%) 0 5 35 16 12 9 9 6 3

[0064] Step 2: design gradation according to Table 1 and take epoxy resin and toughening agent by weight percentage, the dosage of toughening agent is 0.4% of the total mass of coarse aggregate and fine aggregate, and the dosage of epoxy resin is coarse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com