A kind of ferronickel slag ultra-high strength concrete and preparation method thereof

A technology of ultra-high-strength concrete and nickel-iron slag, which is applied in the field of nickel-iron-iron slag ultra-high-strength concrete and its preparation, can solve the problems of inability to increase fluidity, poor concrete fluidity, and low cement hydration rate, and slow down excessive consumption , smooth surface, and the effect of reducing the amount of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The composition and mass percentage of each raw material are as follows: the cementitious material is P.O 52.5 Portland cement 50% (dosage 348kg / m 3 ); mineral powder 15% (amount 104kg / m 3 ); silica fume 5% (35kg / m 3 ); superfine powder of ferronickel slag 30% (dosage 209kg / m 3 ); the fine aggregate is nickel-iron sand crushed through a 4.75mm sieve (amount of 867kg / m 3 ); the coarse aggregate is 5~20mm graded ferronickel slag (dosage 951kg / m 3 ); water (amount 163kg / m 3 ); high-efficiency polycarboxylate superplasticizer (dosage 20kg / m 3 ).

[0037] The preparation method includes: crushing, sieving, grinding process, weighing ingredients and mixing process, and the specific method process is as follows:

[0038] (1) Crushing, screening, and grinding process: Crushing ferronickel slag until the maximum particle size is less than 20mm, sieving and classifying. Those with a particle size of 5-20 mm are directly used as coarse aggregates; those with a particle size...

Embodiment 2

[0042] The composition and mass percentage of each raw material are as follows: the cementitious material is P.O 52.5 Portland cement 60% (amount of 418kg / m 3 ); mineral powder 15% (amount 104kg / m 3 ); silica fume 5% (35kg / m 3 ); superfine powder of ferronickel slag 20% (dosage 139kg / m 3 ); the fine aggregate is nickel-iron sand crushed through a 4.75mm sieve (amount of 867kg / m 3 ); the coarse aggregate is 5~20mm graded ferronickel slag (dosage 951kg / m 3 ); water (amount 163kg / m 3 ); high-efficiency polycarboxylate superplasticizer (dosage 20kg / m 3 ).

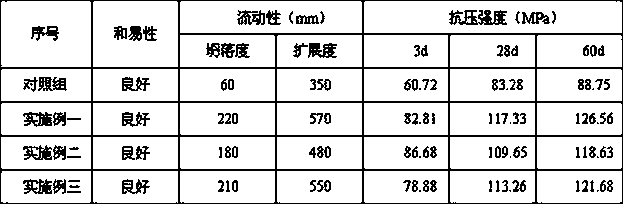

[0043] Others are the same as in Example 1. The workability, fluidity and compressive strength test results of the ferronickel slag ultra-high strength concrete prepared in this example are shown in Table 1.

Embodiment 3

[0045] The composition and mass percentage of each raw material are as follows: the cementitious material is P.O 52.5 Portland cement 55% (dosage 383kg / m 3 ); mineral powder 20% (amount 139kg / m 3 ); silica fume 5% (35kg / m 3 ); superfine powder of ferronickel slag 20% (dosage 139kg / m 3 ); the fine aggregate is nickel-iron sand crushed through a 4.75mm sieve (amount of 867kg / m 3 ); the coarse aggregate is 5~20mm graded ferronickel slag (dosage 951kg / m 3 ); water (amount 163kg / m 3 ); high-efficiency polycarboxylate superplasticizer (dosage 20kg / m 3 ).

[0046] Others are the same as in Example 1. The workability, fluidity and compressive strength test results of the ferronickel slag ultra-high strength concrete prepared in this example are shown in Table 1.

[0047] control group

[0048] At the same time, concrete was prepared with natural crushed stone, river sand and cement as a control. The composition and mass percentage of each raw material of the control group ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com