Recycled concrete with high interface bonding performance and preparation method thereof

A technology of recycled concrete and interface bonding, applied in the field of building materials, can solve the problems of low elastic modulus, high water absorption, poor bonding performance between coarse aggregate and mortar interface, etc. The effect of improving crack resistance and durability, promoting further development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

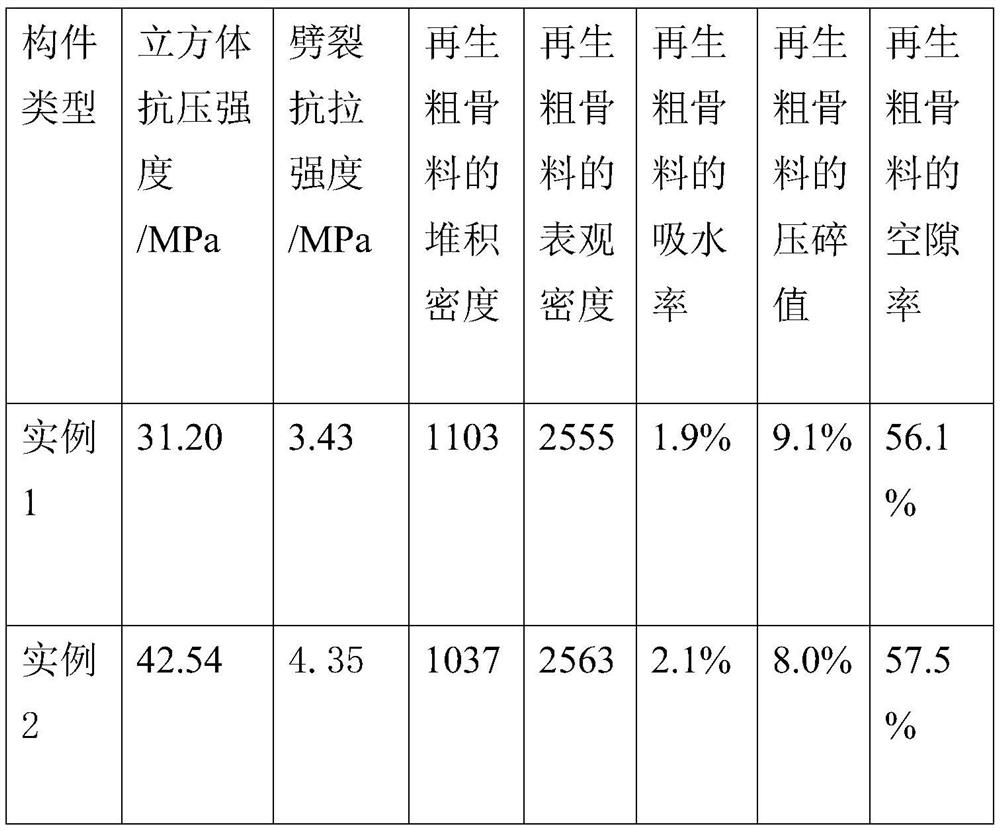

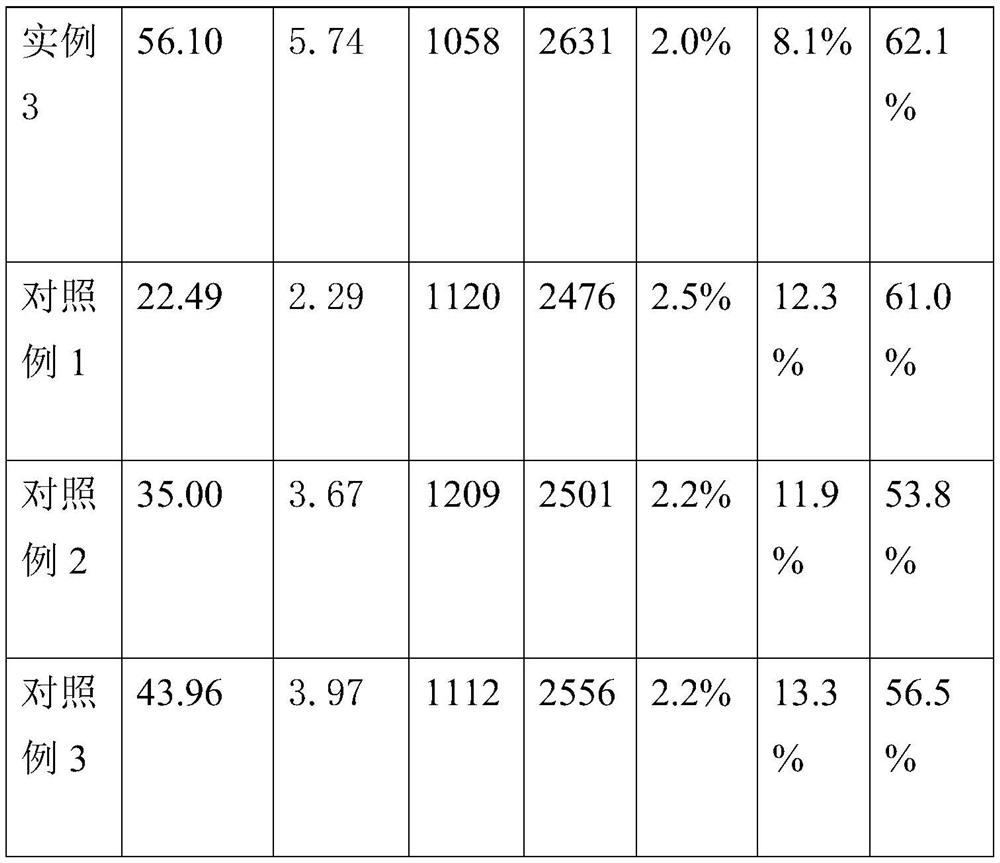

example 1

[0038] A preparation method of recycled concrete with high interfacial bonding performance, 190 parts of water, 223.5 parts of cement, 665 parts of sand, 108 parts of a styrene / acrylic polymer latex, and a styrene / acrylate polymer latex 1290.9 parts of regenerated coarse aggregate, 11.2 parts of silica fume, 33.5 parts of fly ash, and 22.4 parts of mineral powder strengthened by latex soaking method. The cement used is Conch brand 52.5 ordinary Portland cement, the sand is standard medium sand, and the water is Tap water is available for drinking, and the mortar is 10% of the amount of cement mass mixed with polymer. The above-mentioned preparation method of recycled concrete with high interfacial bonding performance comprises the following steps: step 1) rinsing the forced mixer without obvious water accumulation; step 2) weighing a certain amount of each component according to the established mixing ratio Put the materials into the forced mixer in turn (all the components ex...

example 2

[0040] A preparation method of recycled concrete with high interfacial bonding performance, 200 parts of water, 363.6 parts of cement, 600 parts of sand, 116 parts of a styrene / acrylate polymer latex, and 116 parts of a styrene / acrylate polymer latex 1164.7 parts of regenerated coarse aggregate, 18.2 parts of silica fume, 54.5 parts of fly ash, and 36.4 parts of mineral powder strengthened by latex soaking method. The cement used is Conch brand 52.5 ordinary Portland cement, the sand is standard medium sand, and the water is Tap water is available for drinking, and the mortar is 10% of the amount of cement mass mixed with polymer. The above-mentioned preparation method of recycled concrete with high interfacial bonding performance comprises the following steps: step 1) rinsing the forced mixer without obvious water accumulation; step 2) weighing a certain amount of each component according to the established mixing ratio Put the materials into the forced mixer in turn (all the...

example 3

[0042] A preparation method of recycled concrete with high interface bonding performance, 210 parts of water, 608.7 parts of cement, 405 parts of sand, 122 parts of styrene / acrylate polymer latex, a kind of styrene / acrylate polymer 991.6 parts of regenerated coarse aggregate strengthened by latex soaking method, 30.4 parts of silica fume, 91.3 parts of fly ash, 60.9 parts of mineral powder, 15.2 parts of water reducing agent, of which the cement used is Conch brand 52.5 ordinary Portland cement, and sand is the standard The medium sand, the water is drinking tap water, and the mortar is a polymer mixed with an amount of 10% of the cement mass. The above-mentioned preparation method of recycled concrete with high interfacial bonding performance comprises the following steps: step 1) rinsing the forced mixer without obvious water accumulation; step 2) weighing a certain amount of each component according to the established mixing ratio Put the materials into the forced mixer in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com