Preparation method and application of biological calcium carbonate uniformly reinforced recycled aggregate

A bio-calcium carbonate and recycled aggregate technology, which is applied in the field of recycled aggregates for building materials, can solve the problems of uneven distribution of mineralized sedimentary calcium carbonate, weak bonding on the surface of recycled aggregates, and impact on the performance of recycled aggregates. Achieve the effect of sustainable development, uniform reinforcement of recycled aggregate, good promotion prospects and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

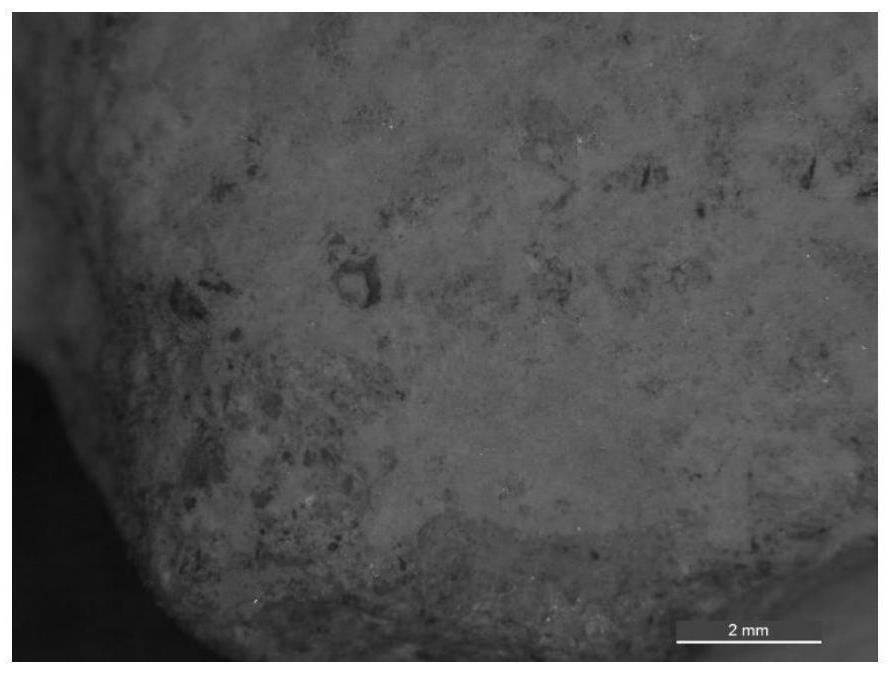

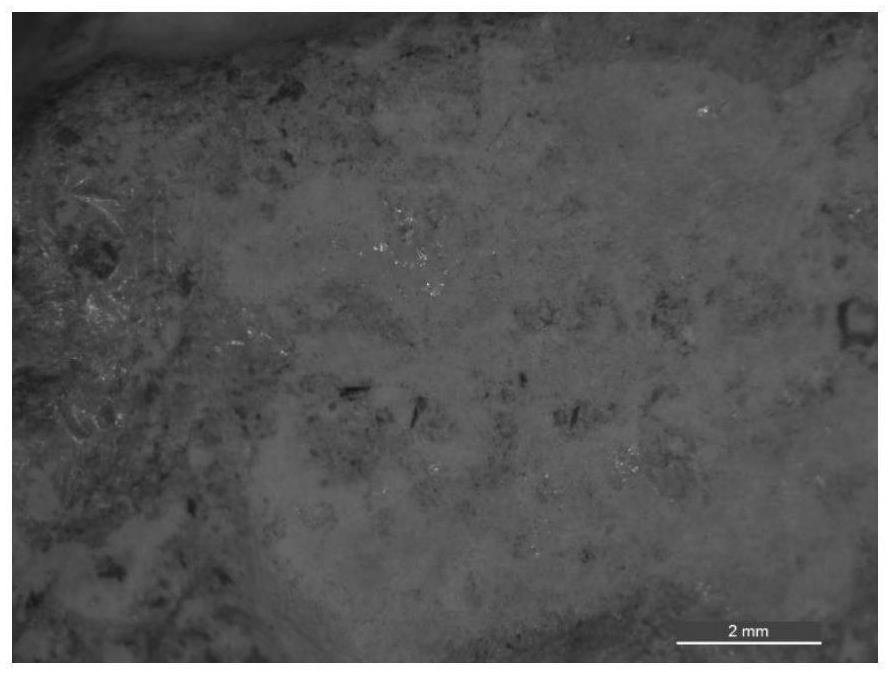

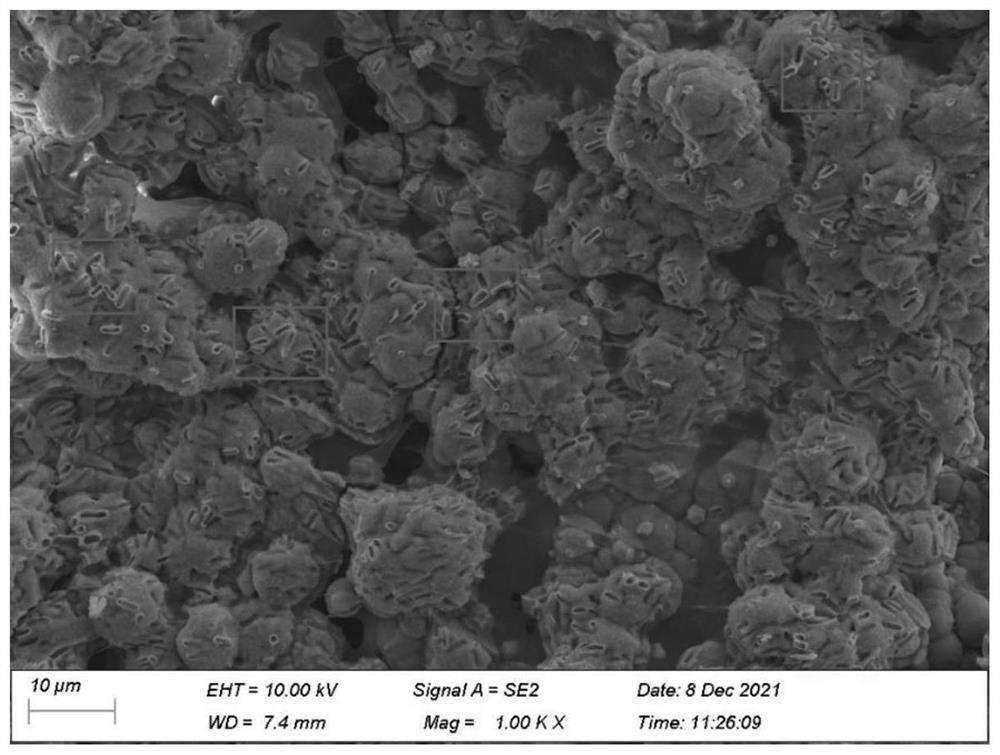

[0039] (1) Pour the pre-mineralized treatment liquid into the container containing the regenerated aggregate, until the pre-treated mineralized treatment liquid completely soaks the regenerated aggregate, and then the container is placed at room temperature for 24 hours;

[0040] In this step, the concentrations of urea and calcium nitrate in the pre-mineralization treatment solution are both 1 mol / L.

[0041] (2) The regenerated aggregate is taken out from the mineralization treatment solution, naturally dried for 1 hour, transferred to the sodium alginate solution containing Bacillus pasteurii and stirred for 30 seconds, and the stirring speed is 60 rpm;

[0042] In this step, the sodium alginate solution containing Bacillus pasteuri is prepared by centrifuging and resuspending the cultured bacterial solution, adding it to the sodium alginate aqueous solution, mixing and stirring, and the bacterial concentration in the solution is 10 9 CFU / ml, the mass concentration of sodiu...

Embodiment 2

[0047] (1) Pour the pre-mineralized treatment liquid into the container containing the regenerated aggregate, until the pre-treated mineralized treatment liquid completely soaks the regenerated aggregate, and then the container is placed at room temperature for 24 hours;

[0048] In this step, the concentrations of urea and calcium nitrate in the pre-mineralization treatment solution are both 1.5 mol / L.

[0049] (2) the regenerated aggregate is taken out from the mineralization treatment solution, naturally dried for 1 hour, transferred to the sodium alginate solution containing bacillus pasteuri and stirred for 60 seconds, and the stirring speed is 60 rmp;

[0050] In this step, the sodium alginate solution containing Bacillus pasteuri is prepared by centrifuging and resuspending the cultured bacterial solution, adding it to the sodium alginate aqueous solution, mixing and stirring, and the bacterial concentration in the solution is 10 9 CFU / ml, the mass concentration of sodi...

Embodiment 3

[0055] (1) Pour the pre-mineralized treatment liquid into the container containing the regenerated aggregate, until the pre-treated mineralized treatment liquid completely soaks the regenerated aggregate, and then the container is placed at room temperature for 24 hours;

[0056] In this step, the concentrations of urea and calcium nitrate in the pre-mineralization treatment solution are both 1 mol / L.

[0057] (2) the regenerated aggregate is taken out from the mineralization treatment solution, naturally dried for 1 hour, transferred to the sodium alginate solution containing bacillus pasteuri and stirred for 90 seconds, and the stirring speed is 40 rmp;

[0058] In this step, the sodium alginate solution containing Bacillus pasteuri is prepared by centrifuging and resuspending the cultured bacterial solution, adding it to the sodium alginate aqueous solution, mixing and stirring, and the bacterial concentration in the solution is 10 9 CFU / ml, the mass concentration of sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com