Wafer surface bonding technology and semiconductor device structure

A bonding process and device structure technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve problems such as poor performance, low degree of dangling bonding, and lack of bonding power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

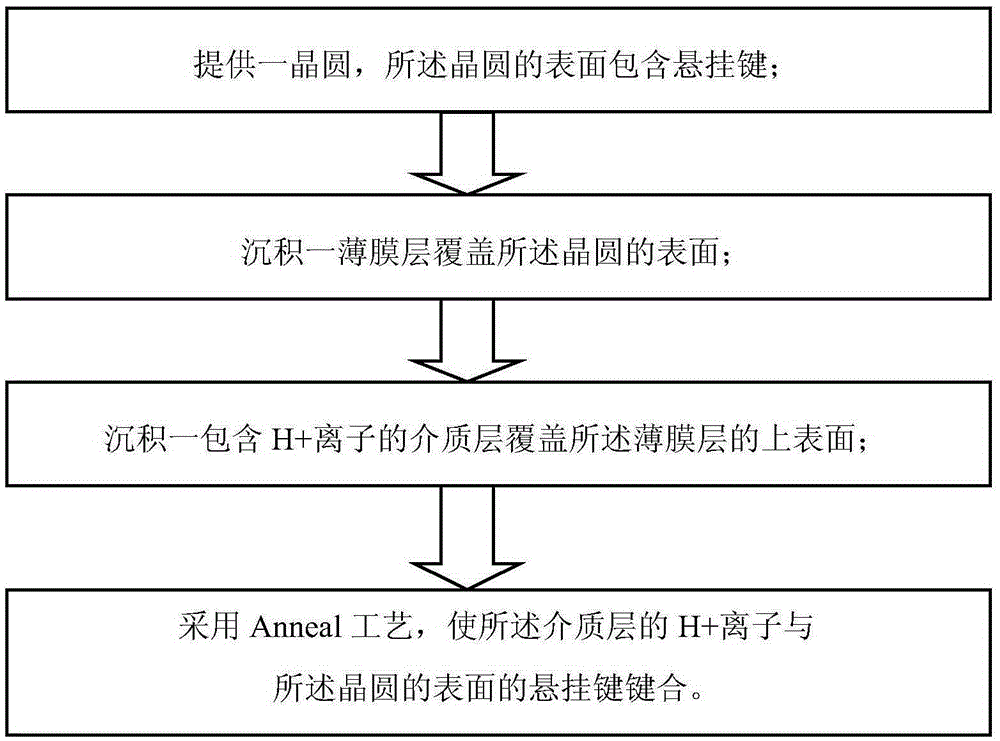

[0026] see figure 1 As shown in the structure, the present invention provides a wafer surface bonding process, which specifically includes:

[0027] First, a wafer 1 is provided, the surface of the wafer 1 is made of Si, and the surface of the wafer 1 contains dangling bonds, see Figure 2a shown.

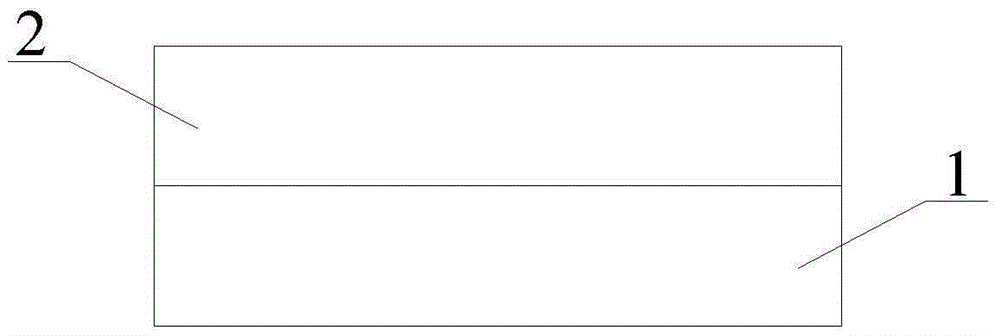

[0028] Secondly, deposit a film layer and cover the surface of wafer 1, preferably, refer to Figure 2b As shown, first deposit a first thin film layer 2, preferably, the first thin film layer 2 is a high-K dielectric layer, wherein the first thin film layer 2 covers the upper surface of the wafer 1; see Figure 2c As shown, a second thin film layer 3 is deposited, preferably, the second thin film layer is a silicon oxide layer, and the second thin film layer 3 covers the upper surface of the first thin film layer 2 .

[0029] Continue to deposit a dielectric layer 4 that contains H+ ions, see Figure 2d As shown, preferably, the dielectric layer 4 is a SiN layer, the dielectri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com