Rock asphalt fluid fine grinding modification mixing process

A mixing process, rock asphalt technology, applied in construction, building components, grain processing, etc., can solve the problem of low modification ability of rock asphalt, and achieve the effect of improving the degree of bonding and improving the fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

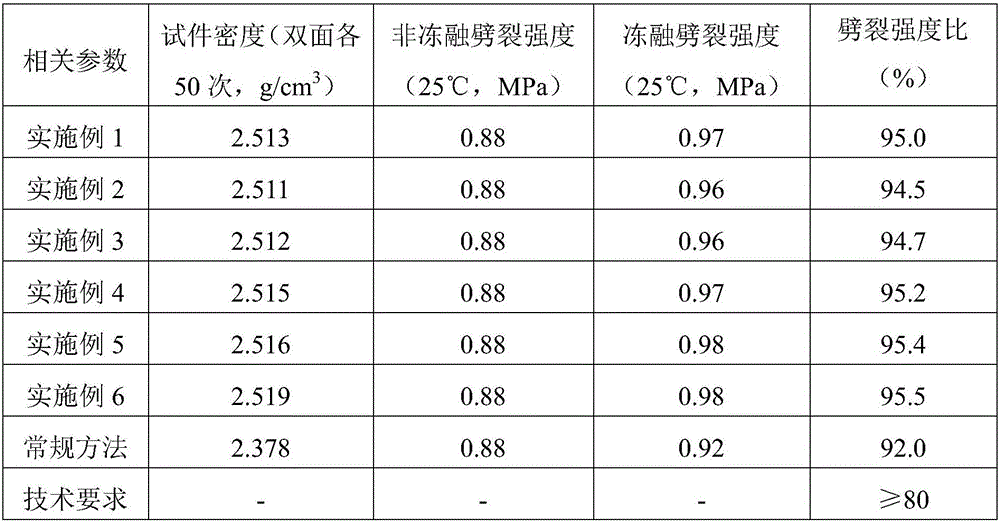

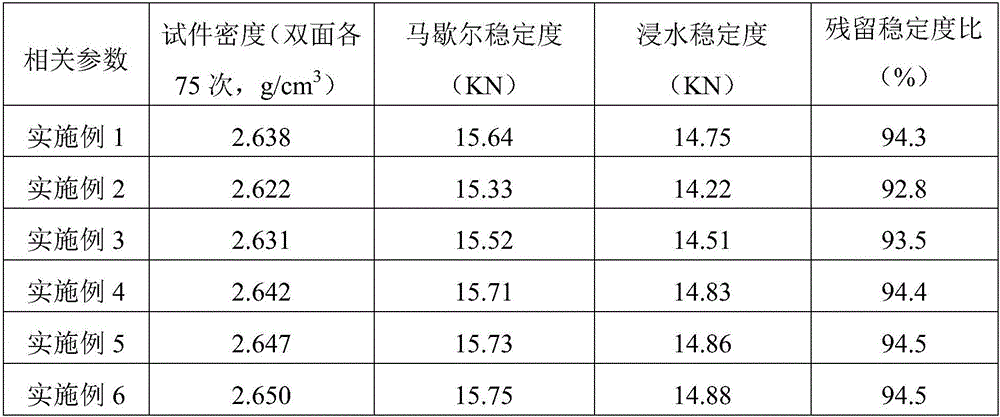

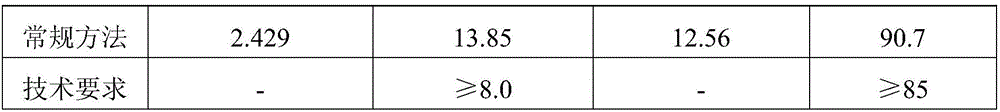

Examples

Embodiment 1

[0015] Embodiment 1 of the present invention provides a kind of asphalt fluid fine grinding modified mixing process, comprising the following steps:

[0016] (1) Crushing rock asphalt to a particle size of less than 5mm, dehydrating and activating at 150-180°C, and controlling the water content of the dehydrated rock asphalt to be below 5%;

[0017] Among them, after the rock asphalt is activated, in order to avoid the increase of water content in the rock asphalt, the rock asphalt can be dried and protected, and the water content of the rock asphalt under drying protection can be controlled below 3%.

[0018] (2) Shearing and milling the activated rock asphalt until the fineness is -150 mesh, the temperature of the shearing mill is 150-180° C., and the shearing speed is 2000-2700 rpm;

[0019] (3) Glue the shear-milled rock asphalt and base asphalt at 150-180°C for 10 minutes.

Embodiment 2

[0021] Embodiment 2 of the present invention provides a kind of asphalt fluid fine grinding modified mixing process, comprising the following steps:

[0022] (1) Crushing rock asphalt to a particle size of less than 5mm, dehydrating and activating at 150-180°C, and controlling the water content of the dehydrated rock asphalt to be below 5%;

[0023] Among them, after the rock asphalt is activated, in order to avoid the increase of water content in the rock asphalt, the rock asphalt can be dried and protected, and the water content of the rock asphalt under drying protection can be controlled below 3%.

[0024] (2) Shearing and milling the activated rock asphalt until the fineness is -150 mesh, the temperature of the shearing mill is 150-180° C., and the shearing speed is 2000-2700 rpm;

[0025] (3) Glue the shear-milled rock asphalt and base asphalt at 150-180° C. for 9 minutes.

Embodiment 3

[0027] Embodiment 3 of the present invention provides a kind of asphalt fluid fine grinding modified mixing process, comprising the following steps:

[0028] (1) Crushing rock asphalt to a particle size of less than 5mm, dehydrating and activating at 150-180°C, and controlling the water content of the dehydrated rock asphalt to be below 5%;

[0029] Among them, after the rock asphalt is activated, in order to avoid the increase of water content in the rock asphalt, the rock asphalt can be dried and protected, and the water content of the rock asphalt under drying protection can be controlled below 3%.

[0030] (2) Shearing and milling the activated rock asphalt until the fineness is -150 mesh, the temperature of the shearing mill is 150-180° C., and the shearing speed is 2000-2700 rpm;

[0031] (3) Glue the shear-milled rock asphalt and base asphalt at 150-180°C for 12 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com