Tire

A tire and tread technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problem of wear resistance reduction, and achieve the effect of improved handling stability, good low and good handling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0163] (Preparation of rubber composition)

[0164] Within the scope of not impairing the purpose of the present invention, the rubber composition of the present invention may contain various agents commonly used in the rubber industry, such as vulcanizing agents, vulcanization accelerators, process oils, anti-aging agents, Anti-scorch agent, zinc oxide, stearic acid, etc.

[0165] Examples of the vulcanizing agent include sulfur and the like. The amount of the vulcanizing agent (as sulfur) used in the rubber component is preferably 0.1 to 10.0 parts by mass, more preferably 1.0 to 5.0 parts by mass, based on 100 parts by mass of (A). When the amount is less than 0.1 parts by mass, the breaking strength, wear resistance, and low heat build-up of the vulcanized rubber may decrease, and when it exceeds 10.0 parts by mass, it may cause loss of rubber elasticity.

[0166] The vulcanization accelerator usable in the present invention is not particularly limited, for example, M (2-...

Embodiment

[0173] The present invention will be described in further detail below through examples, but the present invention is by no means limited by these examples.

[0174] In addition, the physical properties of the polymer were measured by the following methods.

[0175] In addition, various characteristics were measured by the following methods.

[0176] "Physical Properties of Unmodified or Modified SBR"

[0177]

[0178] The vinyl bond content (%) was measured by an infrared method (Morrelo method).

[0179]

[0180] Measured by GPC [manufactured by TOSOH CORPORATION, HLC-8020] using a refractometer as a detector, and expressed as a polystyrene-equivalent value using monodisperse polystyrene as a standard. In addition, the column was GMHXL [manufactured by TOSOH CORPORATION], and the eluent was tetrahydrofuran.

[0181] 1+4 , 100℃) Determination>

[0182] According to JIS K6300, the L rotor is preheated for 1 minute, and the rotor operation time is 4 minutes, and it is c...

Synthetic example 1

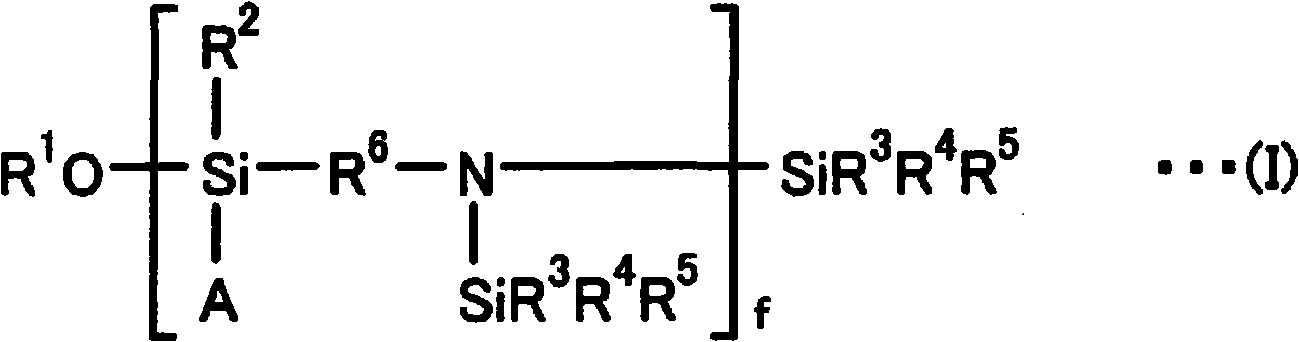

[0196] Synthesis Example 1: Synthesis of N,N-bis(trimethylsilyl)aminopropylmethyldiethoxysilane

[0197] Under a nitrogen atmosphere, 36g of 3-aminopropylmethyldiethoxysilane (manufactured by Gelest) as the aminosilane site was added to 400ml of dichloromethane solvent in a glass flask equipped with a stirrer, and then further in the solution 48 ml of trimethylsilyl chloride (manufactured by Aldrich), 53 ml of triethylamine were added as protective sites, and stirred at room temperature for 17 hours, after which the solvent was removed by placing the reaction solution in an evaporator to obtain a reaction mixture, and further The resulting reaction mixture was distilled under reduced pressure at 665 Pa to obtain 40 g of N,N-bis(trimethylsilyl)aminopropylmethyldiethoxysilane as a 130-135° C. fraction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com