Blast furnace gas dry method bag type dust removing mechanical type pressure dust unloading process and device thereof

A bag-type dust removal and blast furnace gas technology, applied in blast furnaces, dust collectors, blast furnace details, etc., can solve the problems of high energy consumption, short-term, large process gas consumption, etc., and achieve a large cross-sectional area of material flow and interval changes. The effect of less investment and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

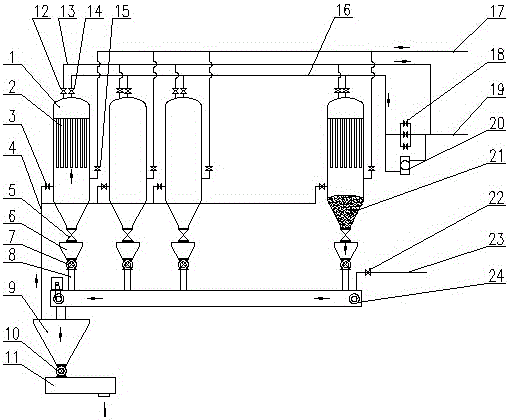

[0027] The blast furnace gas dry method bag type dedusting mechanical type pressure ash unloading process of the present invention comprises steps:

[0028] (1) Steps for constructing pressure relief and recovery system for ash conveying gas under pressure: install the first gas pressure relief valve 3 in the dust gas chamber at the lower part of each baghouse 1, and release the pressure of the first gas corresponding to each baghouse 1 The valve 3 is connected to the centralized ash bin 9 through the first gas pressure relief pipe 4, so that the dust gas under pressure in the centralized ash bin 9 enters the lower dust gas chamber of each bag dust removal box 1 through the first gas pressure relief valve 3; The upper clean gas chamber of each baghouse 1 is provided with a second gas pressure relief valve 12, and the second gas pressure relief valve 12 corresponding to each baghouse 1 is connected to the low-pressure net gas main pipe through the second gas pressure relief pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com