Novel dual-sealing type dome valve

A dome valve and double-sealing technology, which is applied to valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of airbag life not reaching the renewal effect, inconvenient production and maintenance, and increased wear and tear of sealing parts, etc. problems, achieve good sealing, reliable performance and life, and increase the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

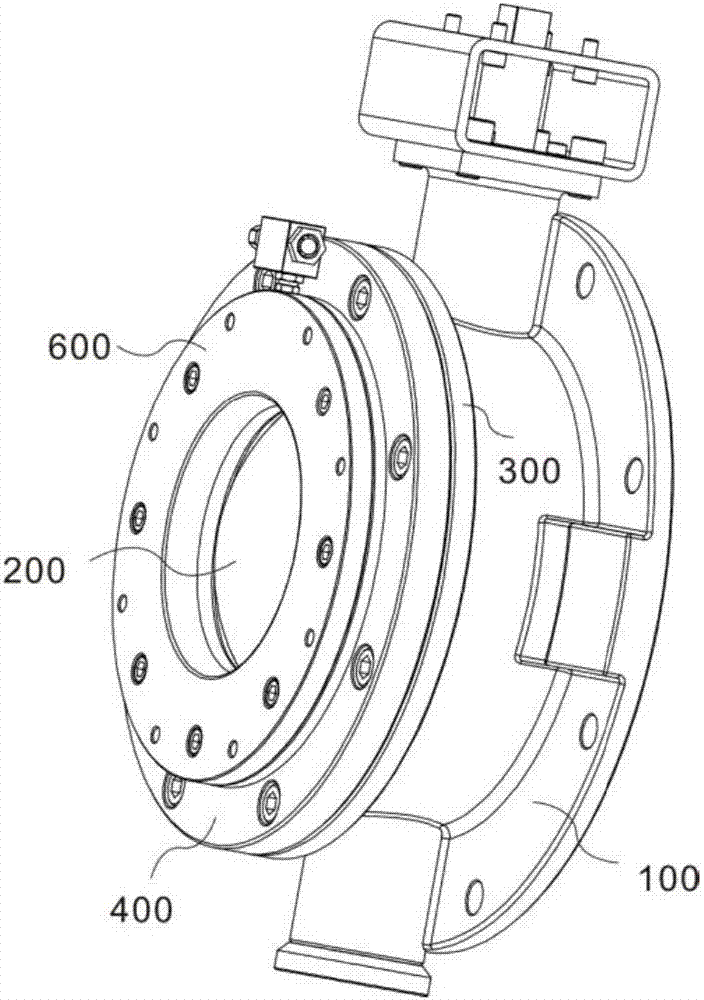

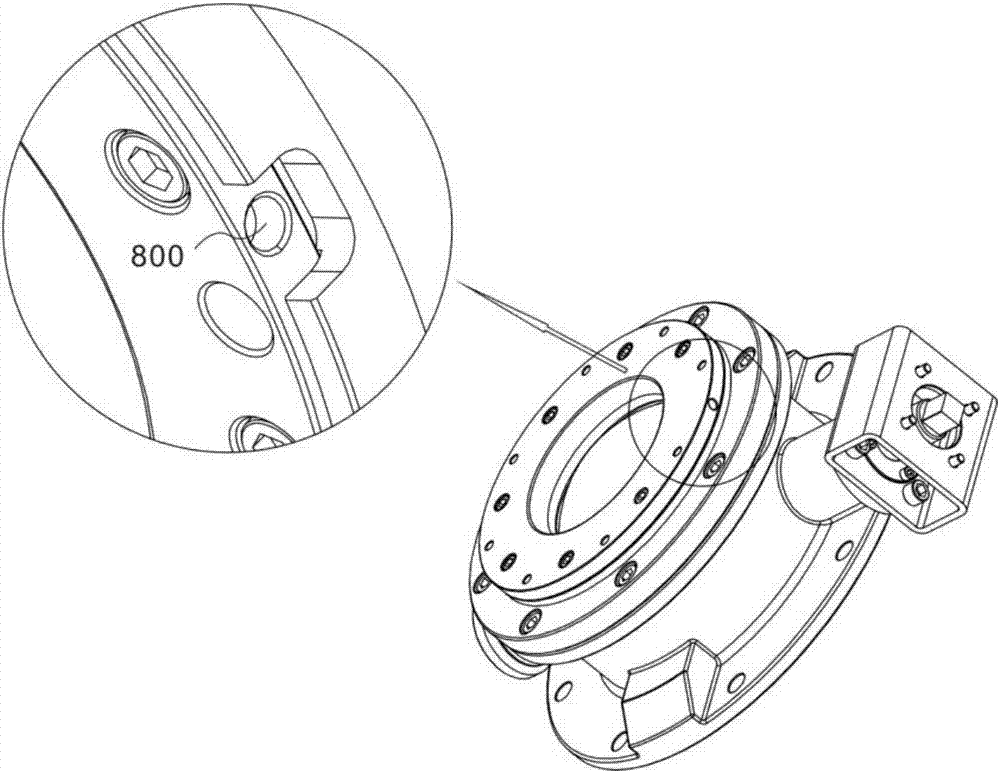

[0037] like figure 1 as shown, figure 1 A schematic diagram of the main structure of a new double-sealed dome valve is shown. Dome valves are often used on pipelines and tanks for gas-solid two-phase injection or transportation to achieve cut-off or shut-off functions. The new double-sealed dome valve in this embodiment includes a valve body 100, a valve core 200 disposed inside the valve body 100, an annular valve seat 300, and a valve cover 400 disposed on the valve seat 300 , wherein, the spool 200 is fixedly connected with the rotating shaft part 500 through screws, and the rotating shaft part 500 drives the spool 200 to move through rotation so as to realize the opening or closing of the new double-sealed dome valve. In order to better realize the sealing of the new double-sealed dome valve, see figure 2 and image 3 , in this embodiment, the new double-sealed dome valve also includes a gland 600, one end of which is fixedly connected to the valve cover 400 by screws...

Embodiment 2

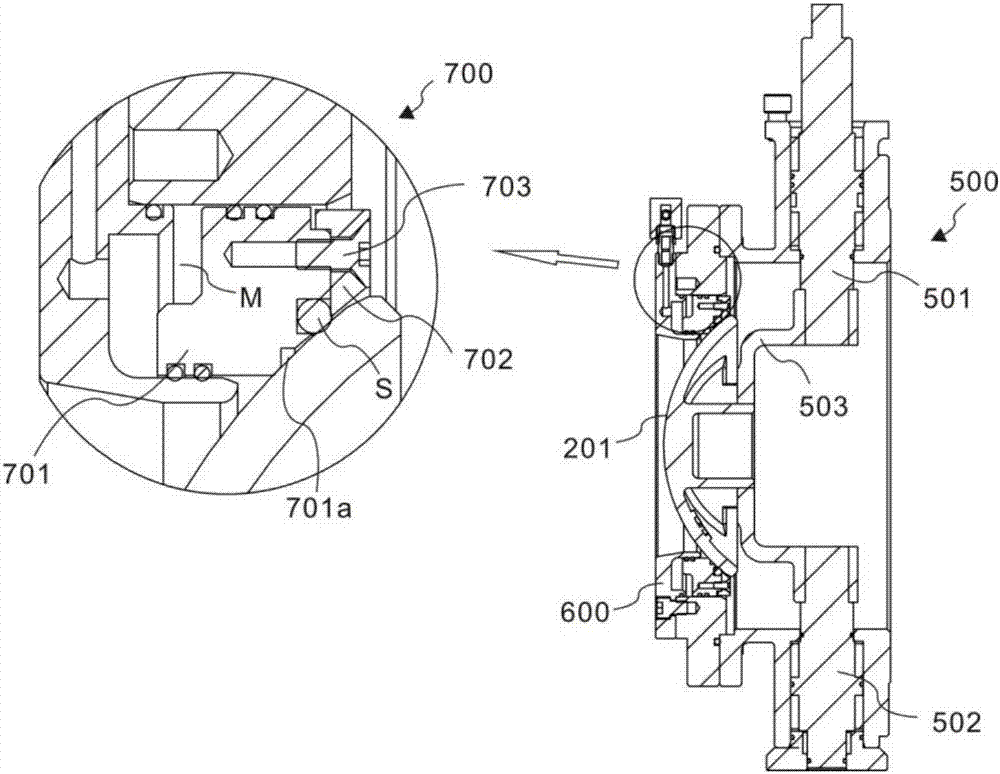

[0041] like Figure 5 and Image 6 shown, and see Figure 1 ~ Figure 4 , the novel double-sealed dome valve in this embodiment, which includes a valve body 100, a valve core 200 disposed inside the valve body 100, an annular valve seat 300, and a valve disposed on the valve seat 300 The cover 400, wherein the valve core 200 is fixedly connected with the rotating shaft part 500 through screws, and the rotating shaft part 500 drives the valve core 200 to move through rotation so as to realize the opening or closing of the new double-sealed dome valve. Here, in order to better realize the opening and closing of the new type double-sealed dome valve, the rotating shaft component 500 includes an upper rotating shaft 501 and a lower rotating shaft 502, and the upper rotating shaft 501 and the lower rotating shaft 502 are connected to the valve core 200 through a rotating arm plate 503 , so as to drive the movement of the spool 200 . In order to better realize the sealing of the n...

Embodiment 3

[0046] like Figure 5 and Image 6 shown, and see Figure 1 ~ Figure 4 , the novel double-sealed dome valve in this embodiment, which includes a valve body 100, a valve core 200 disposed inside the valve body 100, an annular valve seat 300, and a valve disposed on the valve seat 300 The cover 400, wherein the valve core 200 is fixedly connected with the rotating shaft part 500 through screws, and the rotating shaft part 500 drives the valve core 200 to move through rotation so as to realize the opening or closing of the new double-sealed dome valve. Here, in order to better realize the opening and closing of the new type double-sealed dome valve, the rotating shaft component 500 includes an upper rotating shaft 501 and a lower rotating shaft 502, and the upper rotating shaft 501 and the lower rotating shaft 502 are connected to the valve core 200 through a rotating arm plate 503 , so as to drive the movement of the spool 200 . In order to better realize the sealing of the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com