Bearing roller of seat damper

A shock absorber and bearing technology, applied in the field of bearing rollers, can solve problems such as lack of comfort and service life, and achieve the effects of low noise, good wear resistance and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

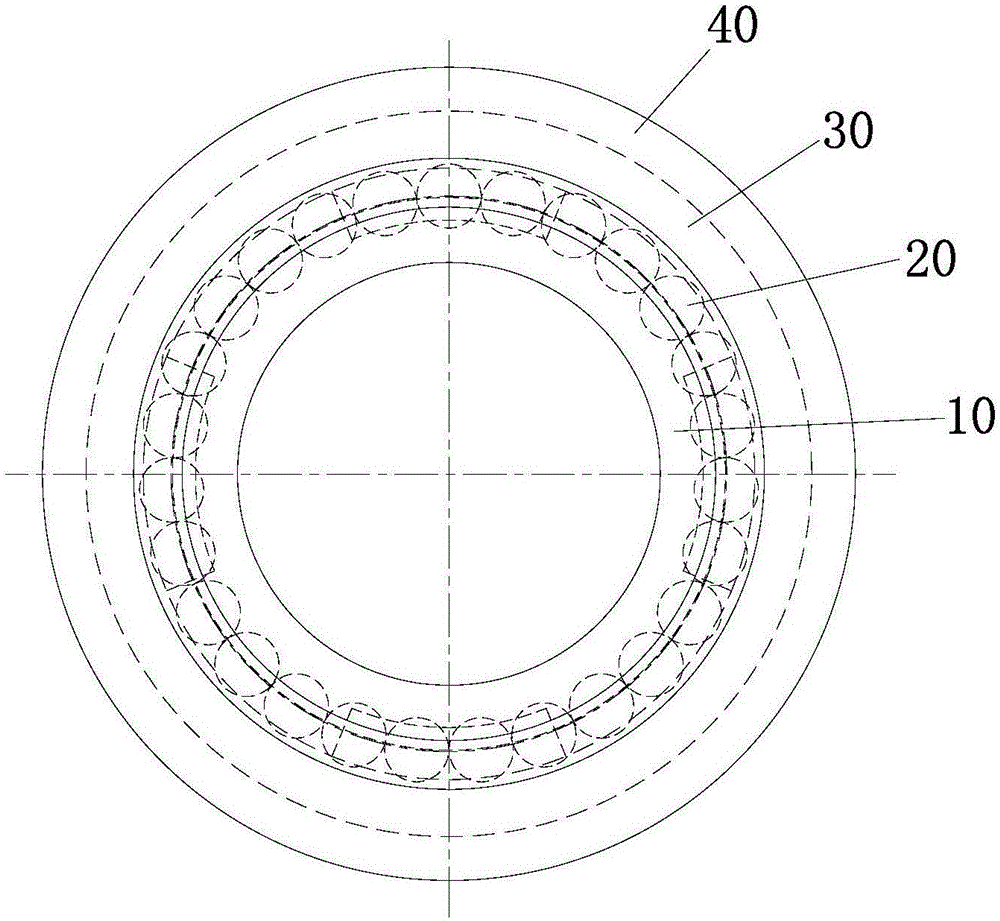

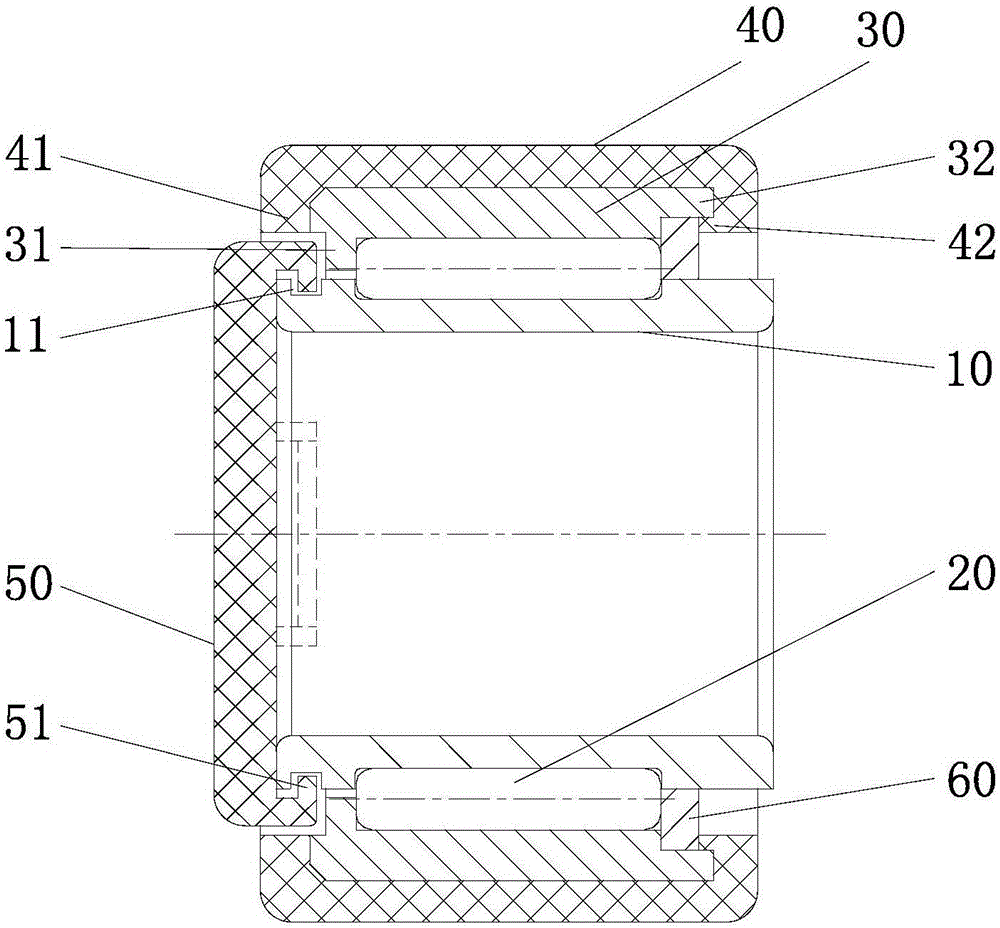

[0021] The present invention will be further described below with specific embodiments in conjunction with the drawings, see figure 1 — Image 6 :

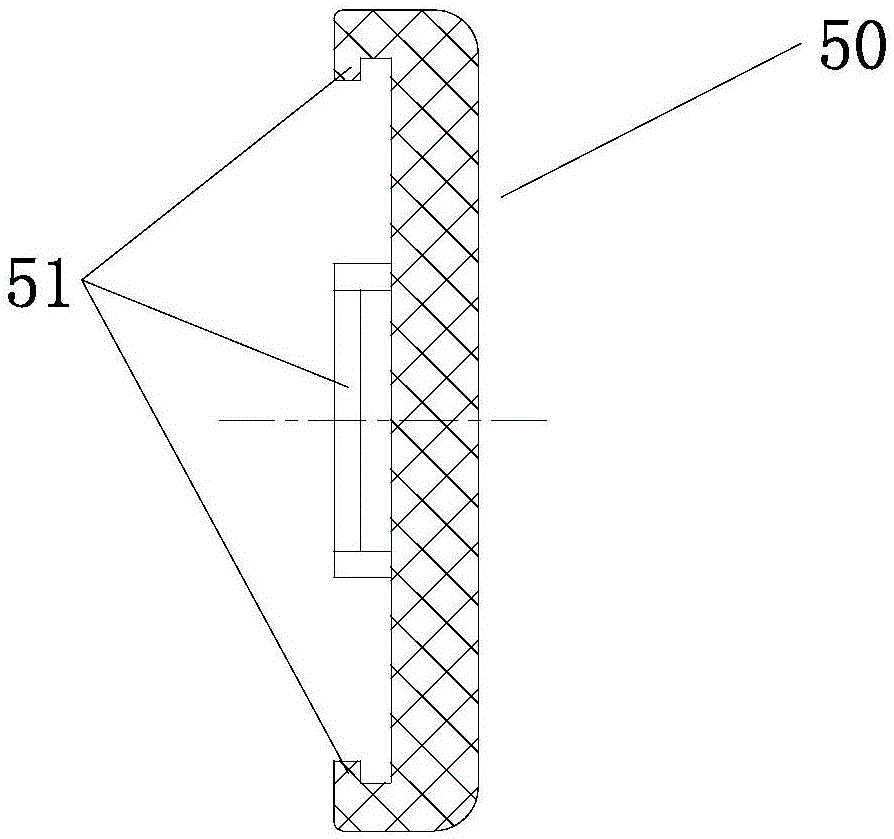

[0022] The bearing roller of the seat shock absorber includes a bearing inner ring 10, a bearing outer ring 30, a roller 20 between the inner and outer rings of the bearing, and a roller retaining ring 60 at one end of the roller 20. The bearing outer ring 30 An annular rolling ring 40 is sleeved on the outer cylindrical surface of the bearing inner ring 10, and a side cover plate 50 is sleeved on one end of the bearing inner ring 10.

[0023] The above-mentioned specific structure of the outer cylindrical surface of the bearing outer ring 30 is covered with an annular rolling ring 40: one side of the bearing outer ring 30 is provided with an inwardly projecting annular protrusion 41 of the limited roller 20, and the bearing outer ring 30 Roller retaining ring 60 is installed on the thin-walled table 32 formed by the expansion of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com