Piezoelectric-static compound micro machine vibration energy collector and manufacture method thereof

A vibration energy harvesting, composite technology, applied in generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, manufacturing microstructure devices, etc., can solve problems such as poor stability and performance, and achieve Avoid device instability and poor performance, improve collection efficiency, and achieve broadband collection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

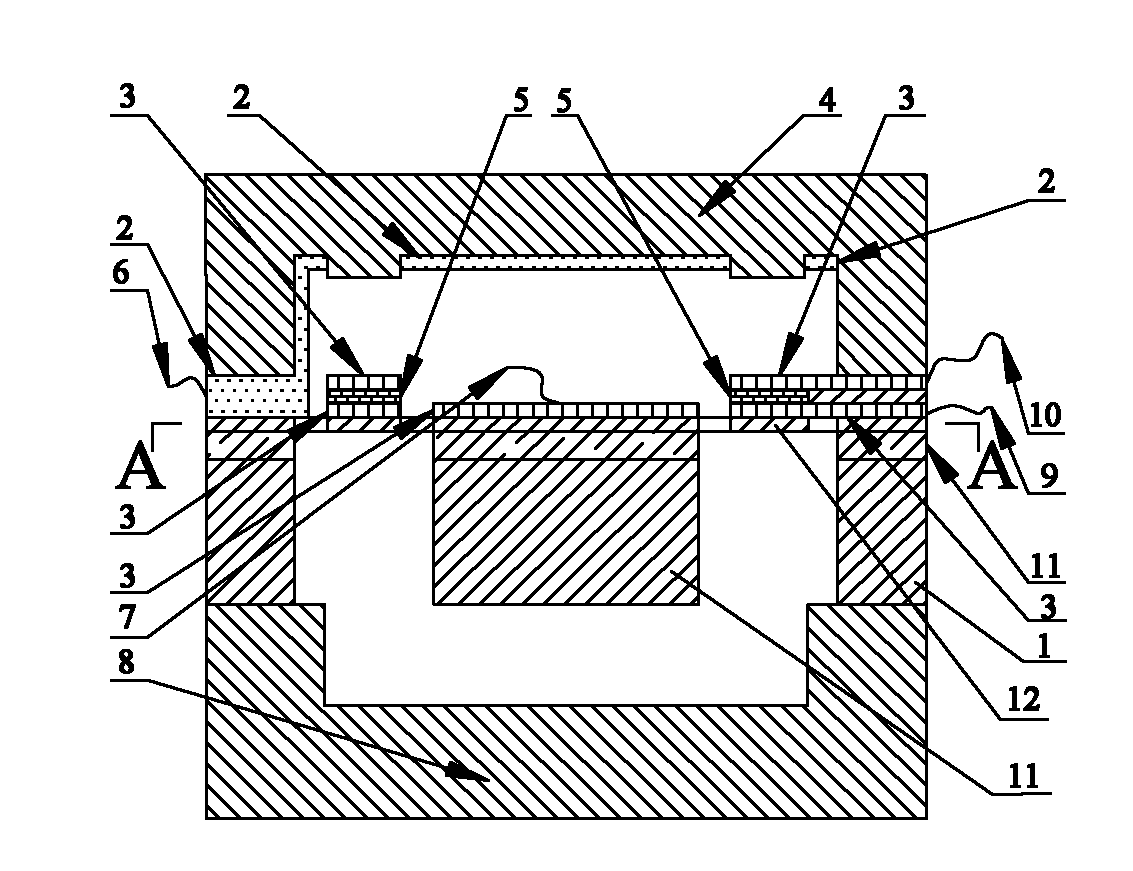

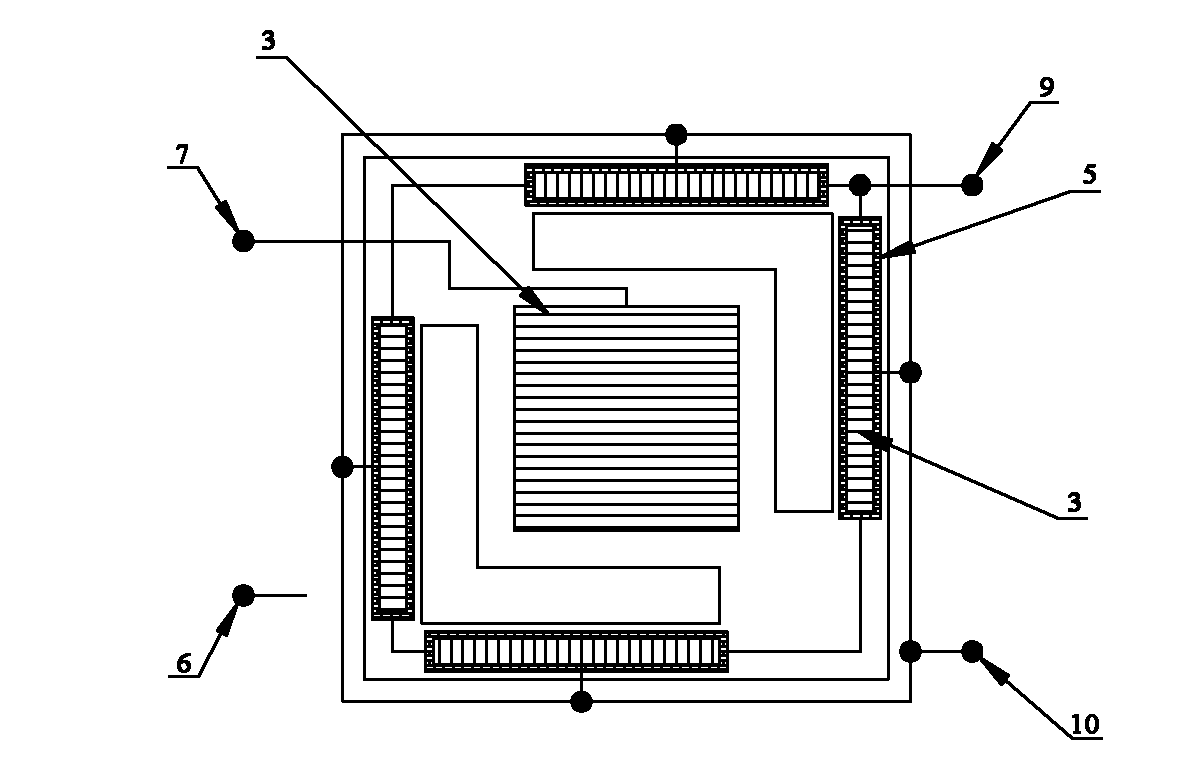

[0069] see Figure 1~3 , the piezoelectric-electrostatic composite micromechanical vibration energy harvester of the present invention is provided with a chip main body and an external circuit of the chip;

[0070] The main body is a three-layer sheet structure, with an upper glass sheet device 4, an SOI sheet device 1, a lower glass sheet device 8, a piezoelectric ceramic sheet group (composed of 4 piezoelectric ceramic sheets 5), piezoelectric ceramic sheet electrodes (there are 4 pairs of electrodes 3) and variable capacitance plate electrodes (1 pair of electrodes made up of upper electrode 2 and lower electrode 3).

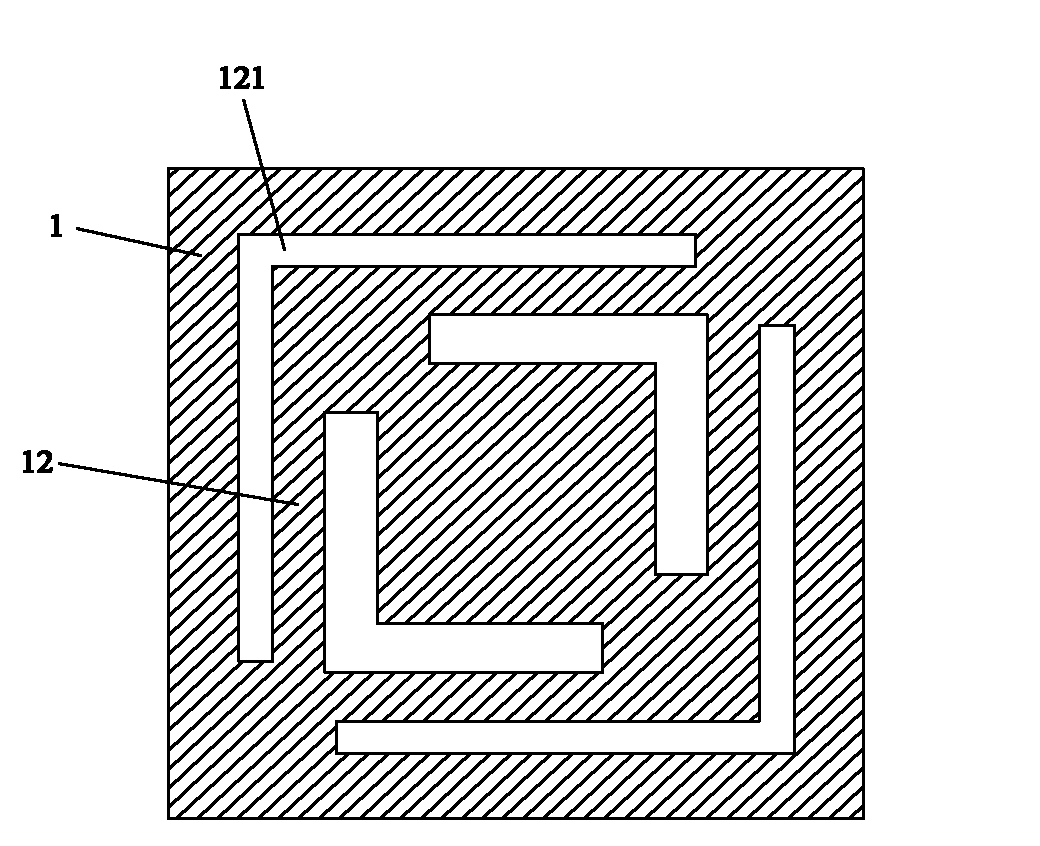

[0071] The cross-sectional shape of the upper glass sheet device 4 is an inverted U shape; the cross-sectional shape of the SOI sheet device 1 is an inverted mountain shape, and the middle part of the SOI sheet device 1 is a mass block 11, and the connecting portion 12 between the mass block 11 and the surrounding wall is set. There are four L-shaped hollow ...

Embodiment 2

[0112] see Figure 8 , similar to Embodiment 1, the only difference is that the external circuit of the chip is different. The external circuit of the chip is provided with a filter capacitor 14 (C), a first switch 15 (SW1), a second switch 17 (SW2), an energy storage capacitor 18 (C s ) and the variable capacitance plate start-up power supply 20; the output end of the variable capacitance plate start-up power supply 20 is connected to the variable capacitor 16 (C through the first switch 15 v ) plate electrode input terminal, the output terminal of the variable capacitor 16 plate electrode is connected to the input terminal of the energy storage capacitor 18 through the second switch 17, and the output terminal of the energy storage capacitor 18 is connected to an external load R. Both the first switch 15 and the second switch 17 are diode switches. The starting power supply 20 of the capacitor plate can directly adopt an external DC power supply, such as a battery or an ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com