Injector Corrosion Isolation Seals

A technology for injectors and sealing components, which is applied to fuel injection devices, engine sealing, special fuel injection devices, etc., and can solve problems such as injectors not working.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following description of the preferred embodiments is merely illustrative in nature and in no way intended to limit the invention, its application or uses.

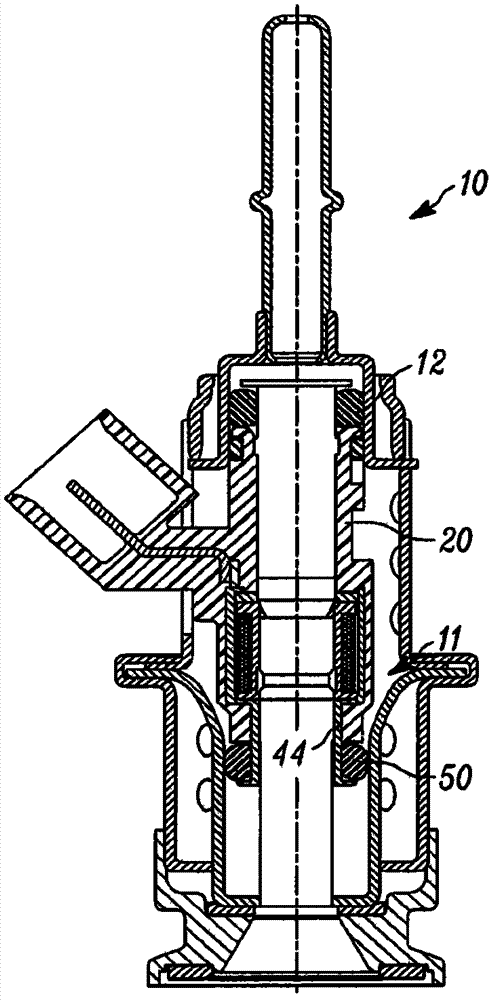

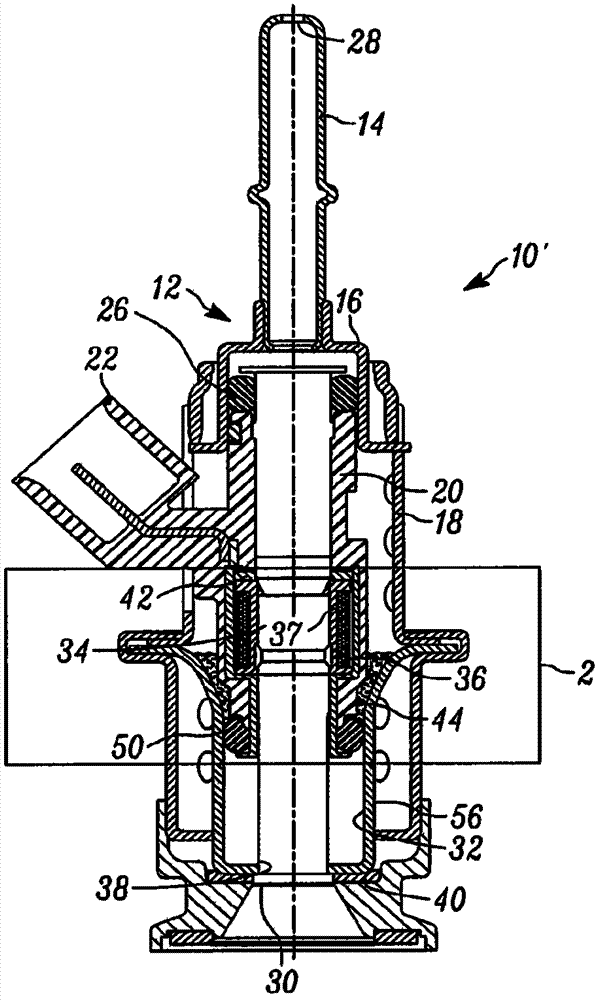

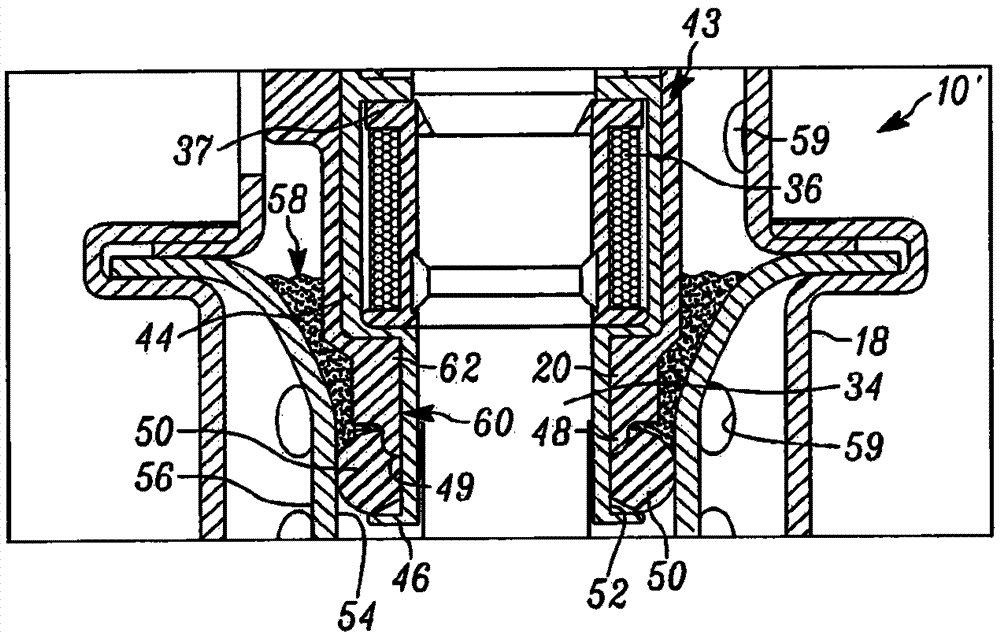

[0014] refer to figure 2 , a fluid injector according to an embodiment of the present invention is shown generally at 10'. The injector 10 ′ includes an inlet cap structure, shown generally at 12 , having a cap tube 14 and an inlet cap 16 . When the injector is configured as an RDU of a vehicle's selective catalytic reduction (SCR) system, the cap pipe 14 can be connected to a source of reductant. The inlet cap 16 is connected to a shroud 18 and the shroud 18 substantially surrounds a portion of the plastic body 20 with the connector 22 .

[0015] A portion of the inlet pipe 24 is disposed within the main body 20 . A primary sealing member 26 , such as an elastomeric O-ring, surrounds a portion of the inlet tube 24 to provide a seal between the inlet tube 24 , the inlet cap 16 and the body 20 .

[0016] Fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com