Fuel injection valve

A fuel injection valve, fuel technology, applied in the direction of fuel injection devices, special fuel injection devices, fuel injection devices with anti-corrosion measures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0020] A fuel injection valve of a first embodiment of the present disclosure injects fuel for combustion of an internal combustion engine from an injection hole. The internal combustion engine is a compression ignition diesel engine, and is installed in a vehicle as a driving source for travel. Fuel (such as light oil) remaining in a fuel tank not shown is pressure-delivered into the common rail by a high-pressure fuel pump, and then distributed from the common rail into each fuel injection valve 10 and injected from the fuel injection valve 10 to the combustion in the room.

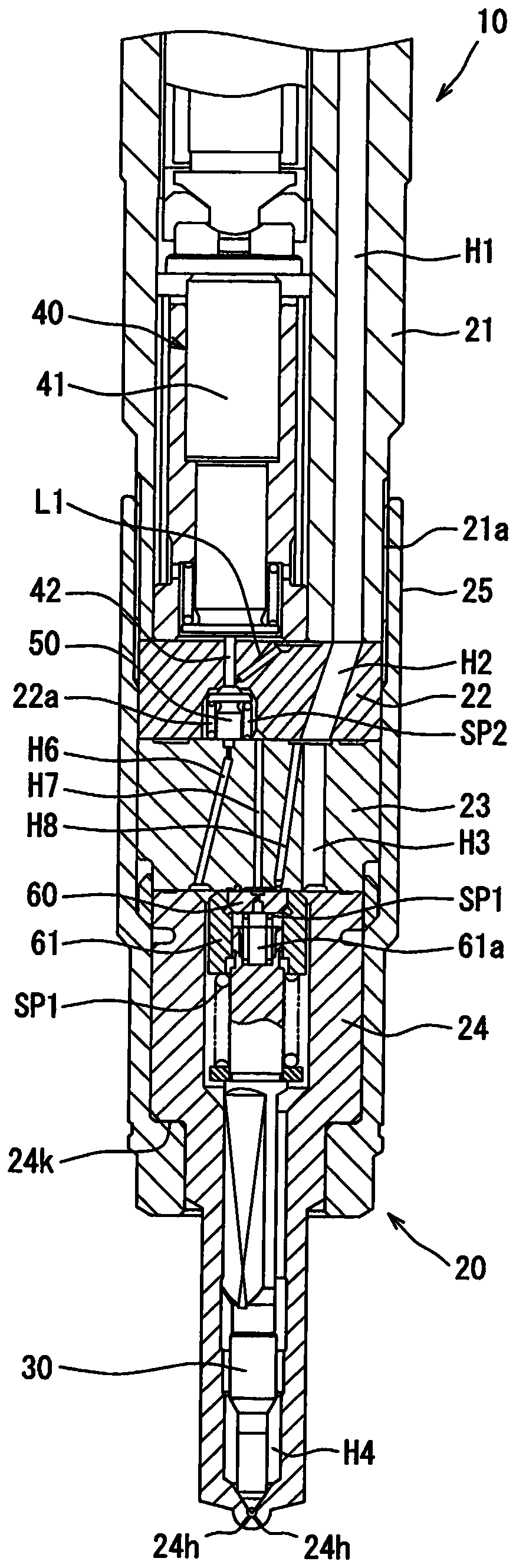

[0021] Such as figure 1 As shown, the fuel injection valve 10 includes a body 20 , a valve needle 30 , a driving part 40 , a control valve element 50 , a control plate 60 and a cylinder 61 .

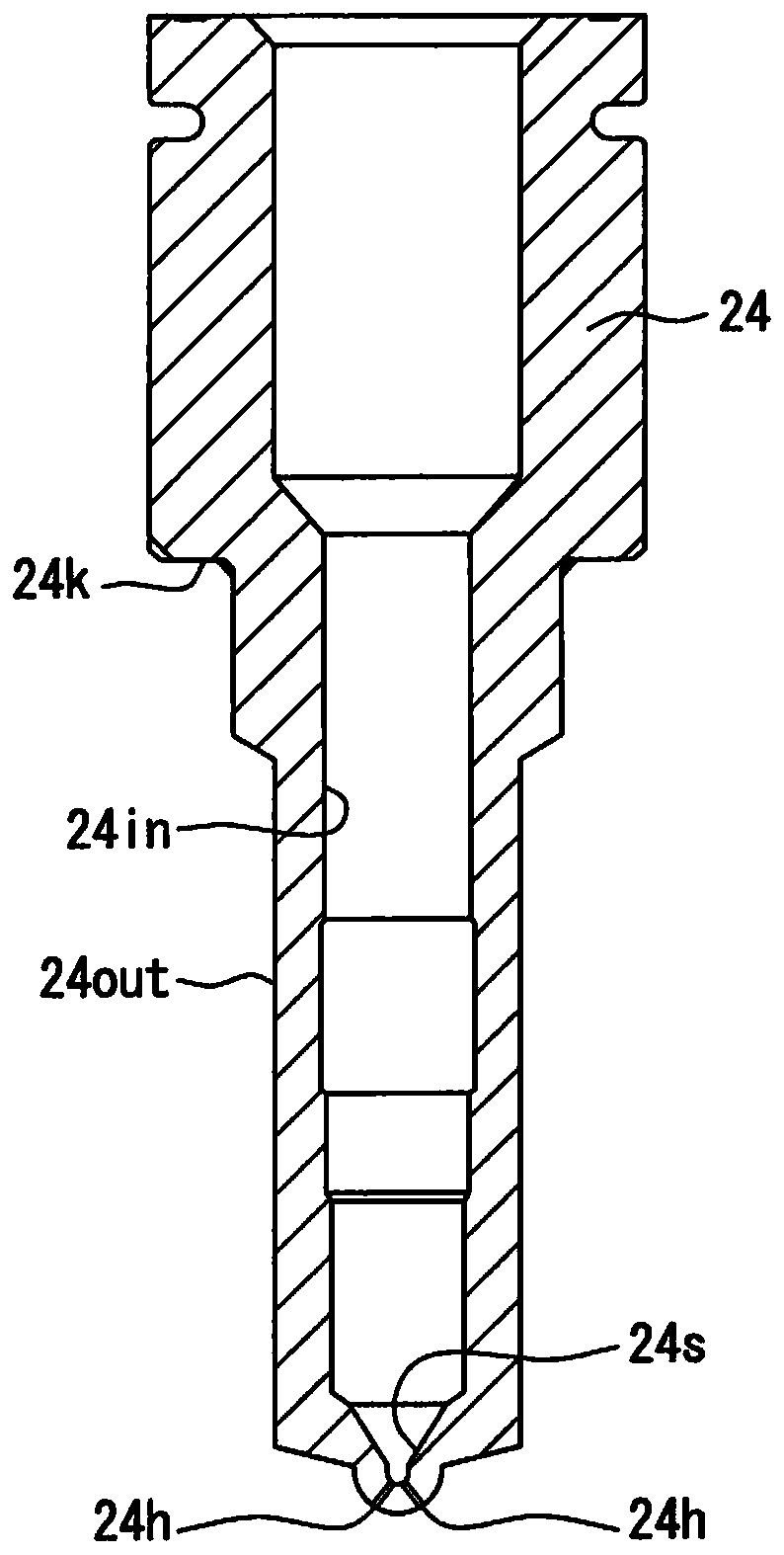

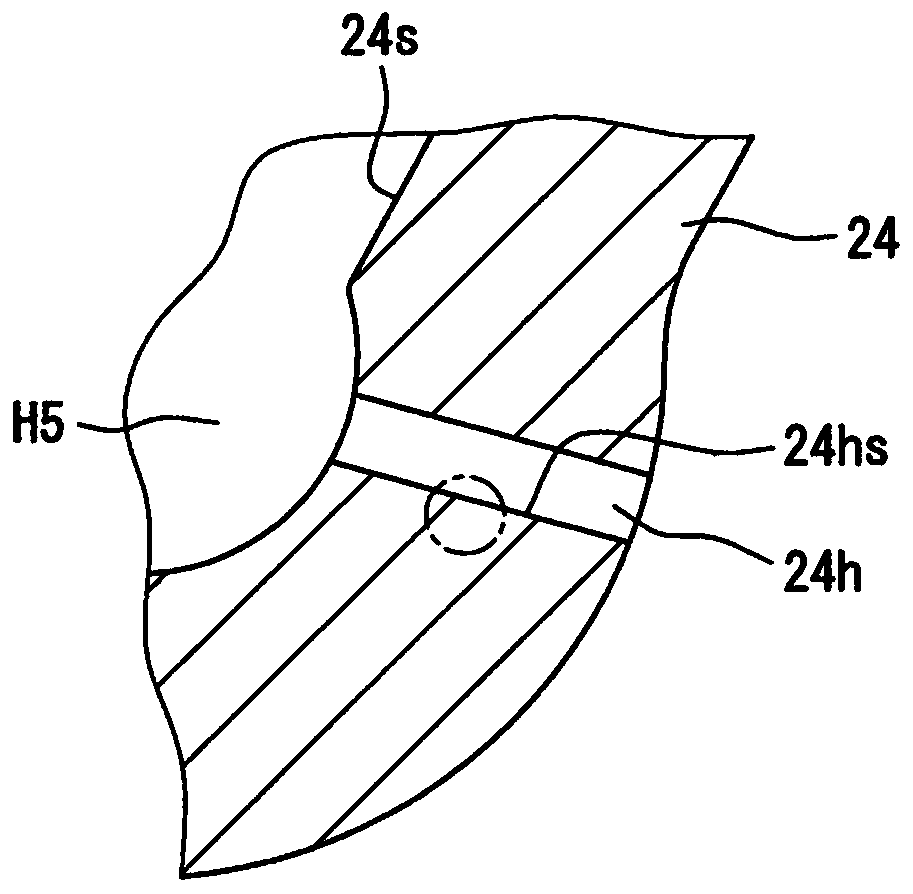

[0022] The body 20 includes a plurality of metal parts, such as a driving part body 21 , a valve plate 22 , an orifice plate 23 , and a valve body 24 , which are combined together by holding nuts 25 . Specifica...

no. 2 example

[0048] Such as Figure 6 As shown, the valve body 24A of the second embodiment has an intermediate layer 244 positioned between a sacrificial corrosion layer 245 and a corrosion resistant layer 242 . The intermediate layer 244 is provided by stacking a plurality of films. exist Figure 6 In , the respective films are indicated as intermediate layers 244a, 244b and 244c.

[0049] Each of the intermediate layers 244a, 244b, and 244c is formed by a method of depositing a film on the surface of the sacrificial etching layer 245 by chemical reaction in the gas phase, that is, by a chemical vapor deposition process. In particular, intermediate layers 244a, 244b, and 244c are desirably formed by atomic layer deposition (ALD), which is a chemical vapor deposition process.

[0050] The intermediate layer 244 has a linear expansion coefficient lower than that of one of the sacrificial corrosion layer 245 and the corrosion-resistant layer 242 and higher than that of the other of the s...

no. 3 example

[0061] Such as Figure 4 As shown, the valve body 24 of the first embodiment has a structure in which a sacrificial corrosion layer 245 and a corrosion-resistant layer 242 are disposed on a base material 241 . On the other hand, if Figure 7 As shown, the valve body 24B of the third embodiment has a structure in which a diffusion preventing layer 243 is provided on a base material 241 in addition to a sacrificial corrosion layer 245 and a corrosion-resistant layer 242 . The diffusion preventing layer 243 will now be described in detail.

[0062] The diffusion barrier layer 243 is located between the base material 241 and the sacrificial corrosion layer 245, and is made of, for example, aluminum oxide (Al 2 o 3 ) in which diffusion of the metal component (for example, iron) of the base material 241 is less likely to occur than in the corrosion-resistant layer 242 and the sacrificial corrosion layer 245. While "diffusion" is known as the phenomenon in which matter is dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com