Pump assembly for supplying fuel, preferably diesel fuel, to an internal combustion engine

A technology for pump components and internal combustion engines, applied to parts of pumping devices for elastic fluids, fuel injection pumps, liquid fuel engines, etc., capable of solving problems such as weakened thread couplings and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

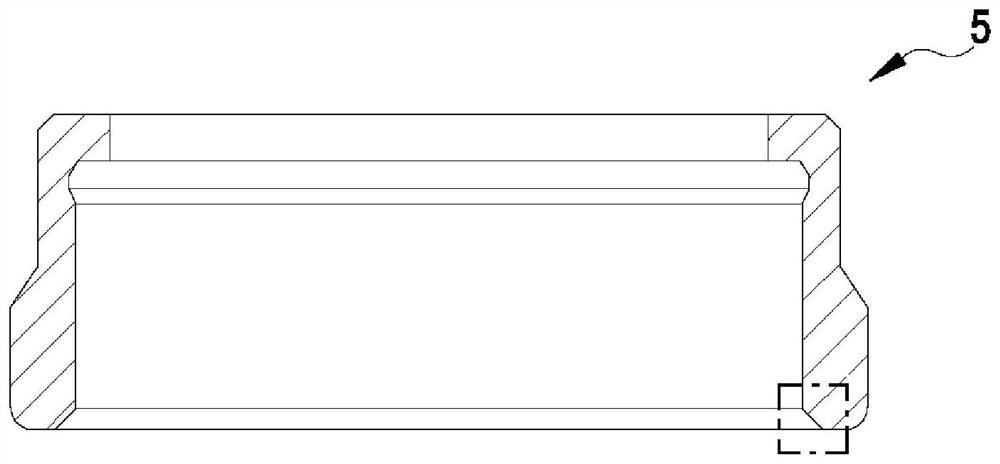

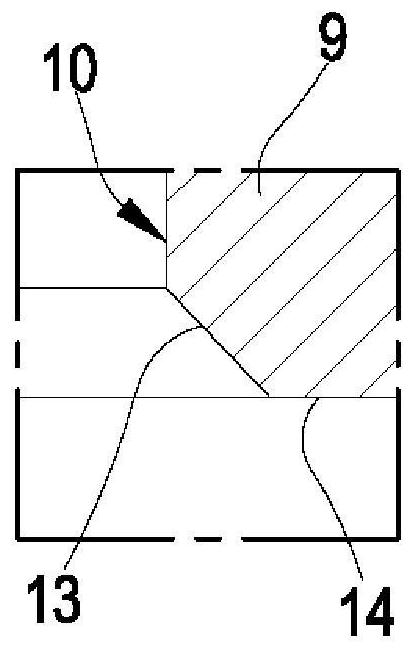

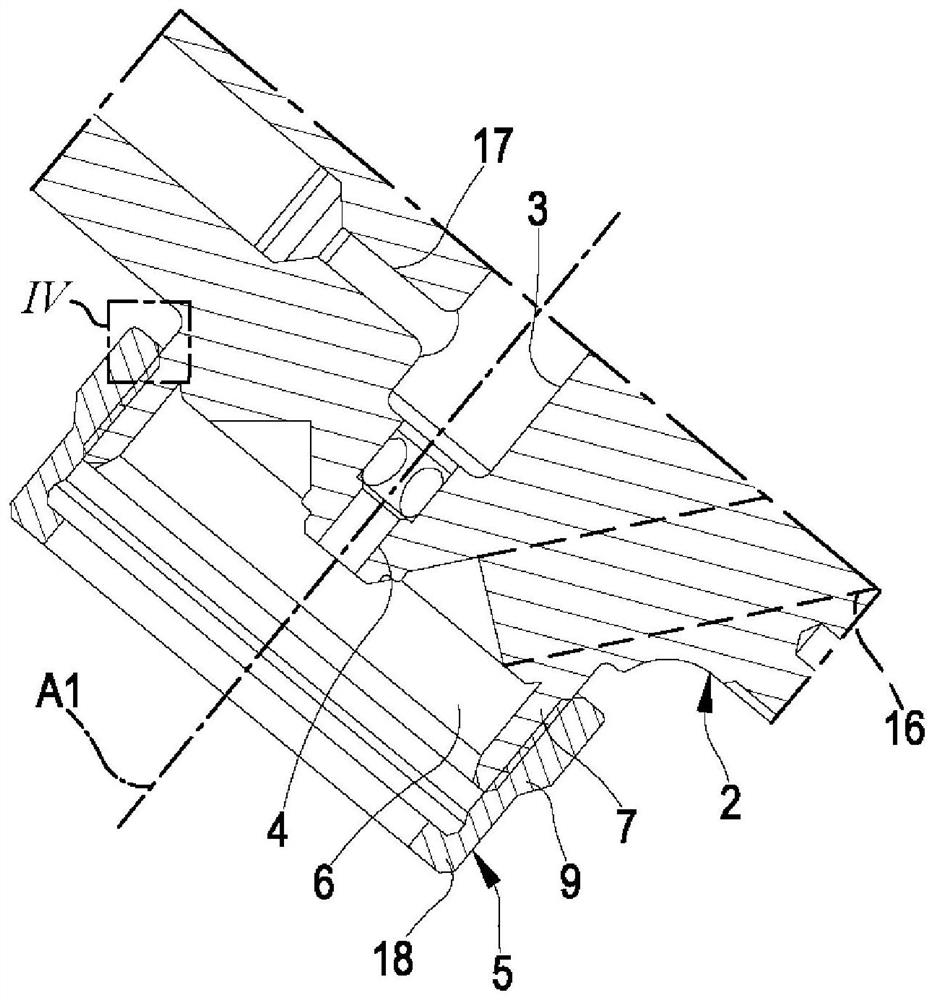

[0049] refer to image 3 , 1 denotes in its entirety a pump assembly for supplying fuel, preferably diesel fuel, to an internal combustion engine (not shown).

[0050]The pump assembly 1 generally comprises a high pressure pump with a pumping piston (partially shown) designed to be able to supply fuel to an internal combustion engine (not shown) and a not shown pre-feed pump, eg of the gear type , the pre-supply pump is designed to be able to supply fuel to the high-pressure pump. The high pressure and gear pumps are driven by shafts (not shown in the drawings).

[0051] The pump 1 includes a pump body (not shown) and a pump head 2 assembled with the pump body. A cylinder 3 is formed in the pump head 2 and extends along the axis A1. A pumping piston (not shown) extends along axis A1 and is slidably coupled to cylinder 3 . A suction duct 16 is formed laterally in the pump head 2 for feeding a suction chamber 6 which partially accommodates an inlet valve (not shown) for cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com