Integrated wood formwork

A wood formwork, integral technology, applied in the direction of formwork/formwork member, formwork/formwork/work frame, formwork/formwork/work frame connection, etc. The joints are easy to damage the wooden square back and the wooden formwork has a short service life, so as to achieve the effects of stable and reliable connection, convenient disassembly and long service life of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

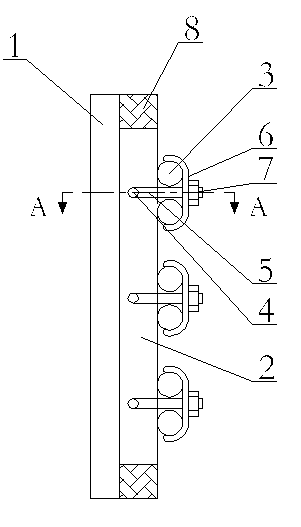

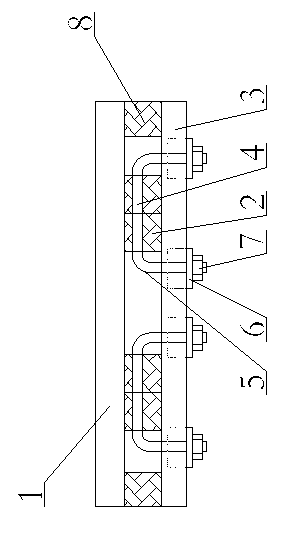

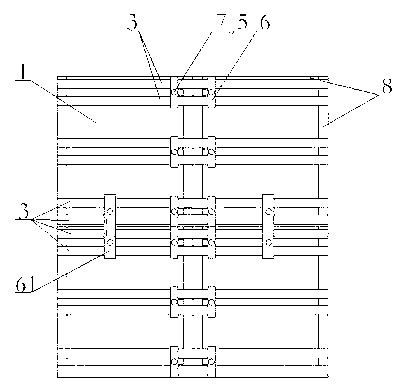

[0018] Figure 1-2 As shown, a combined overall wooden formwork includes a panel 1, a wooden square longitudinal flute 2, a steel pipe horizontal flute 3, a U-shaped hook bolt 5, a "3" type clamp 6, a nut 7 and a wooden square flute 8. The outer surface of the panel 1 is longitudinally and uniformly provided with a plurality of wooden square corrugations 2, and a plurality of steel pipe transverse corrugations 3 are horizontally arranged on the outer surface of the panel 1 and attached to the wooden square corrugations 2, and the wooden square longitudinal corrugations 2 are provided with multiple vertical corrugations. The hook bolt hole 4 in the extending direction of the wooden longitudinal corrugation 2, the U-shaped hook bolt 5 is connected in the hook bolt hole 4, and the two ends of the U-shaped hook bolt 5 are connected with a "3" type card 6, and a "3" type cli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com