Connecting structure of non-metallic pipe and metal plate

A non-metallic pipe and connection structure technology, which is applied to non-detachable pipe connections, pipes/pipe joints/fittings, passing components, etc., can solve the problems of falling off of welds, affecting service life, high labor costs, etc., and achieve stable connection structure , Improve the sealing strength and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

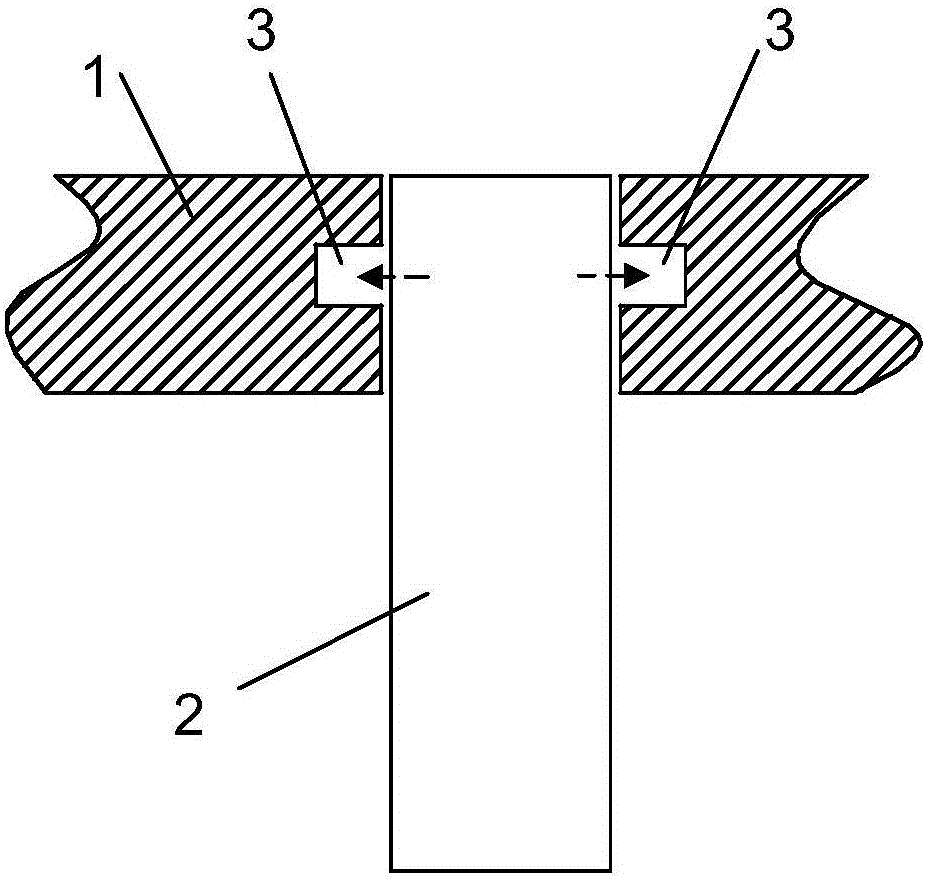

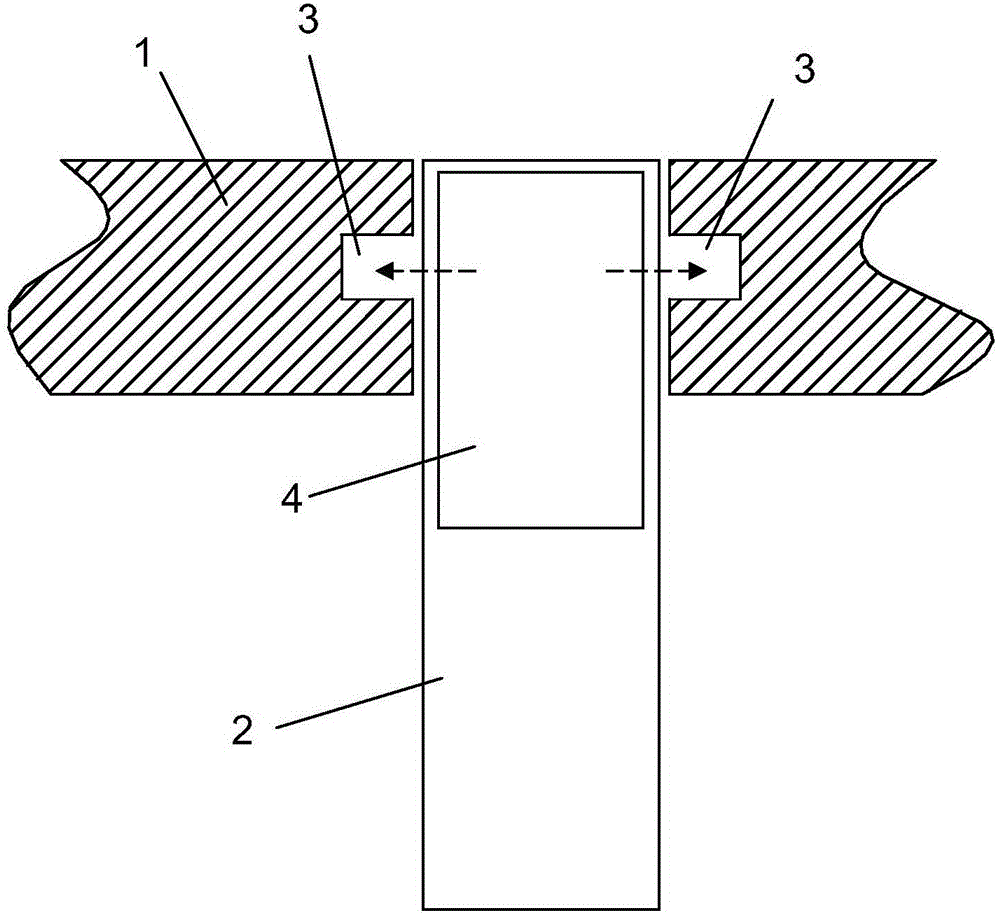

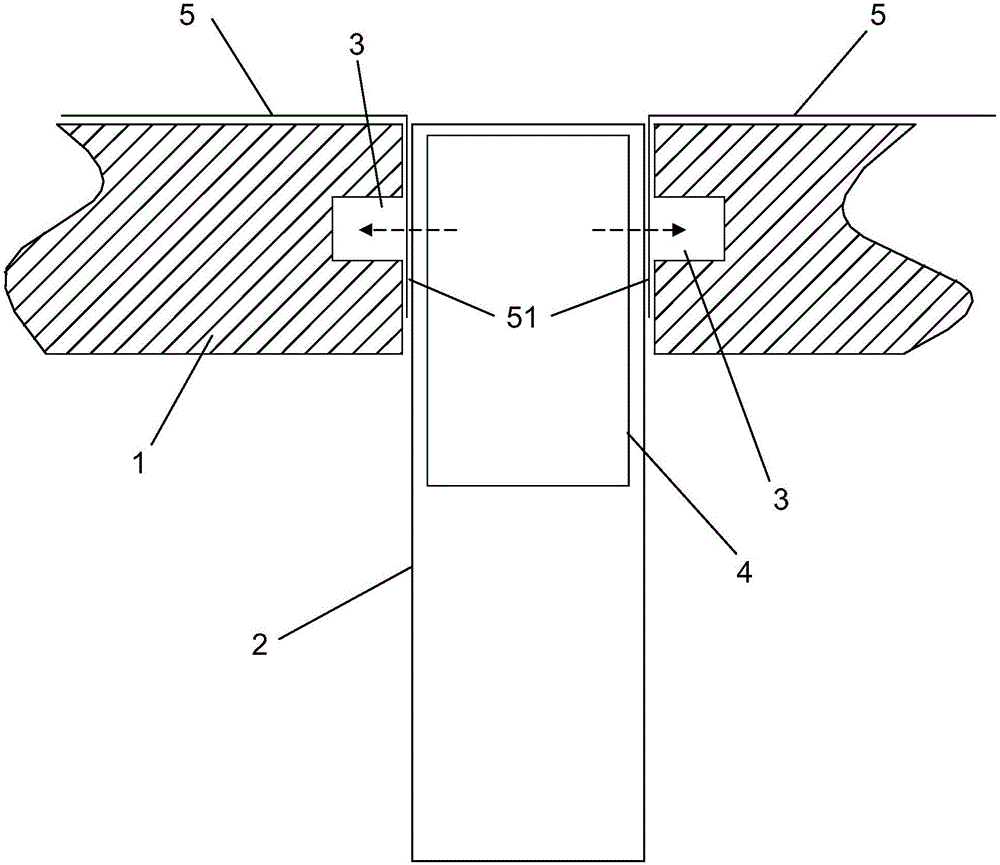

[0024] Please combine Figure 1 to Figure 3 As shown, a connection structure between a non-metallic pipe and a metal plate provided by the present invention includes a metal plate 1 and a non-metallic pipe 2, and the metal plate 1 has an installation hole and is sleeved on the non-metallic pipe 2. A cavity 3 is formed on the inner wall of the installation hole, and the wall of the non-metallic pipe 2 corresponding to the cavity 3 is squeezed into the cavity 3 to form a connection structure with the metal plate 1 . Extrusion can be carried out by means of internal expansion in the tube to extrude outward (see the dotted arrow in the figure).

[0025] The above-mentioned non-metallic pipe 2 can be made of high temperature resistant and corrosion resistant materials. Preferably, the non-metallic pipe 2 can be made of fluorine-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com