Foaming mold and manufacturing method for high-pressure oil pump noise insulation covers

A technology of foaming molds and manufacturing methods, which is applied in the field of auto parts manufacturing, can solve problems such as low production efficiency, unstable quality, falling off, etc., and achieve the effects of improving production efficiency, convenient and reliable operation, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

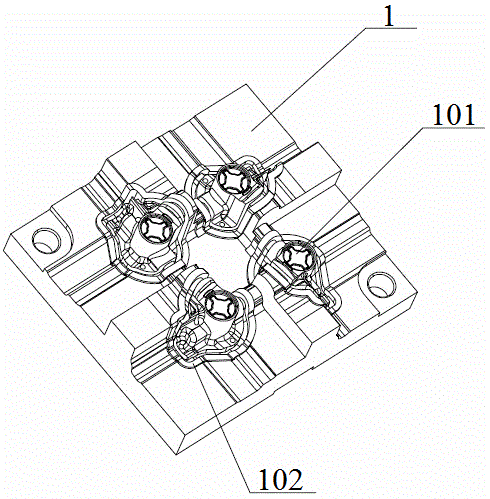

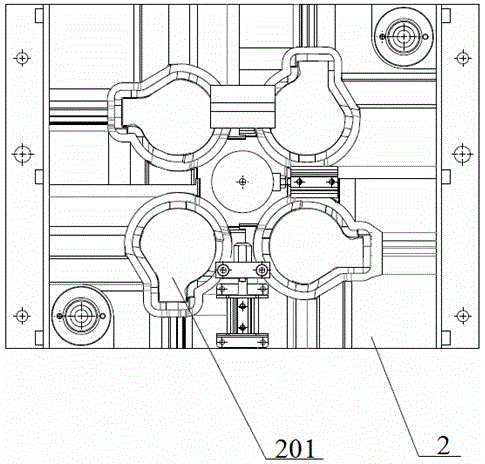

[0025] Such as figure 1 and figure 2 , this embodiment relates to a foaming mold, including an upper mold 1 and a lower mold 2, the top of the lower mold 2 is provided with at least one groove 201 for embedding an oil pump cover, and the bottom of the lower mold 2 is provided with An inflatable airbag (not shown in the figure) that vertically lifts the lower mold 2; at least one core 101 is correspondingly provided at the bottom of the upper mold 1, and when the upper mold 1 and the lower mold 2 are closed, Each core 101 enters into the oil pump cover embedded in the corresponding groove 201, a molding space is formed between the core 101 and the corresponding oil pump cover, and the top of the upper mold 1 A feeding mechanism is provided to supply materials to each of the molding spaces when the mold is closed; multiple water pipes (not shown in the figure) are uniformly arranged in the upper mold 1 and the lower mold 2, and each of the The inlet ends of the water pipes ar...

Embodiment 2

[0030] The embodiment of the present invention relates to a method for manufacturing a sound-proof cover of a high-pressure oil pump, using the above-mentioned foaming mold, including the following steps:

[0031] Step 1, an oil pump cover is embedded in each of the grooves 201 of the foaming mold.

[0032] Step 2, inflating the inflatable air bag to close the upper mold 1 and the lower mold 2; in this step, the inflation pressure is controlled to be 0.2-0.25 MPa.

[0033] Step three, lock the mold.

[0034] Step 4, pouring, injecting foaming material into each of the molding spaces through the feeding mechanism.

[0035] Step 5, control the foaming time, and control the foaming temperature by supplying hot water to each water pipe; after the foaming time is up, deflate the inflatable air bag and open the mold. The foaming time is controlled at about 6 minutes / mould.

[0036] Wherein, in step 1, hot water can be supplied to each water pipe, so that the upper mold 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com