Thermally driven deformable micromirror

A micromirror-shaped, thermally driven technology, applied in optical components, optics, instruments, etc., can solve the problems of complex preparation process, small deformation, and high driving voltage, and achieve a simplified preparation process, low production difficulty, and improved heating efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the accompanying drawings and examples.

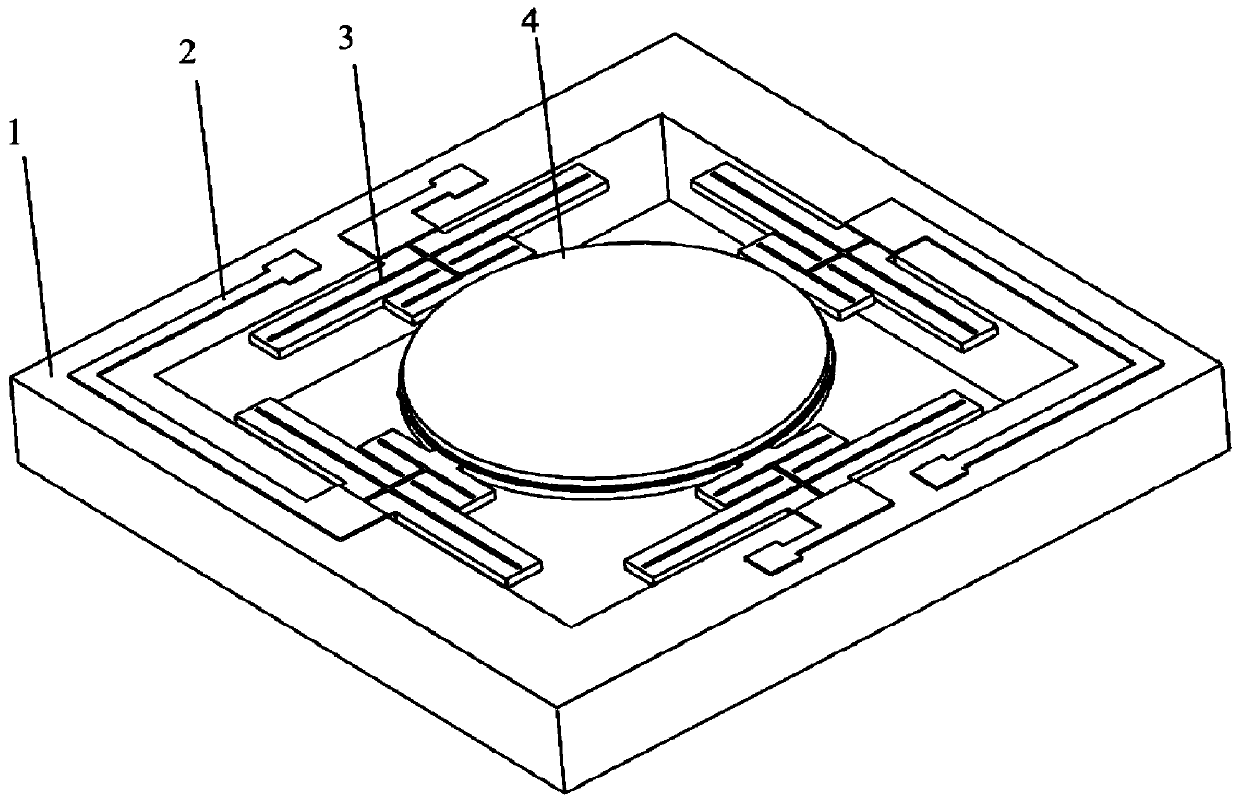

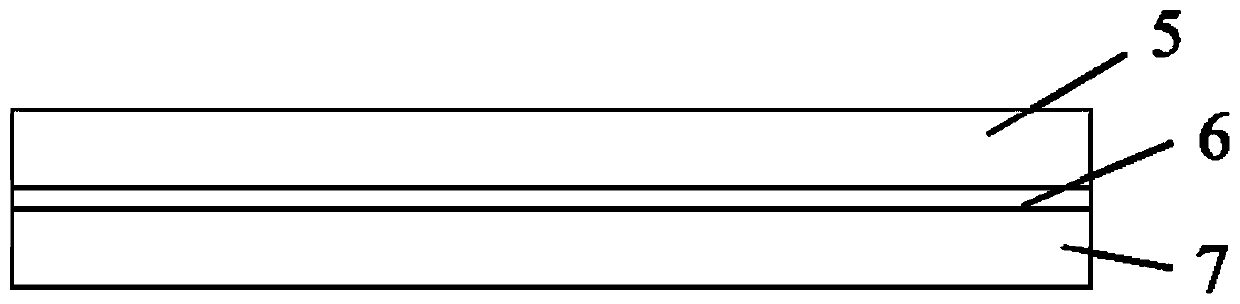

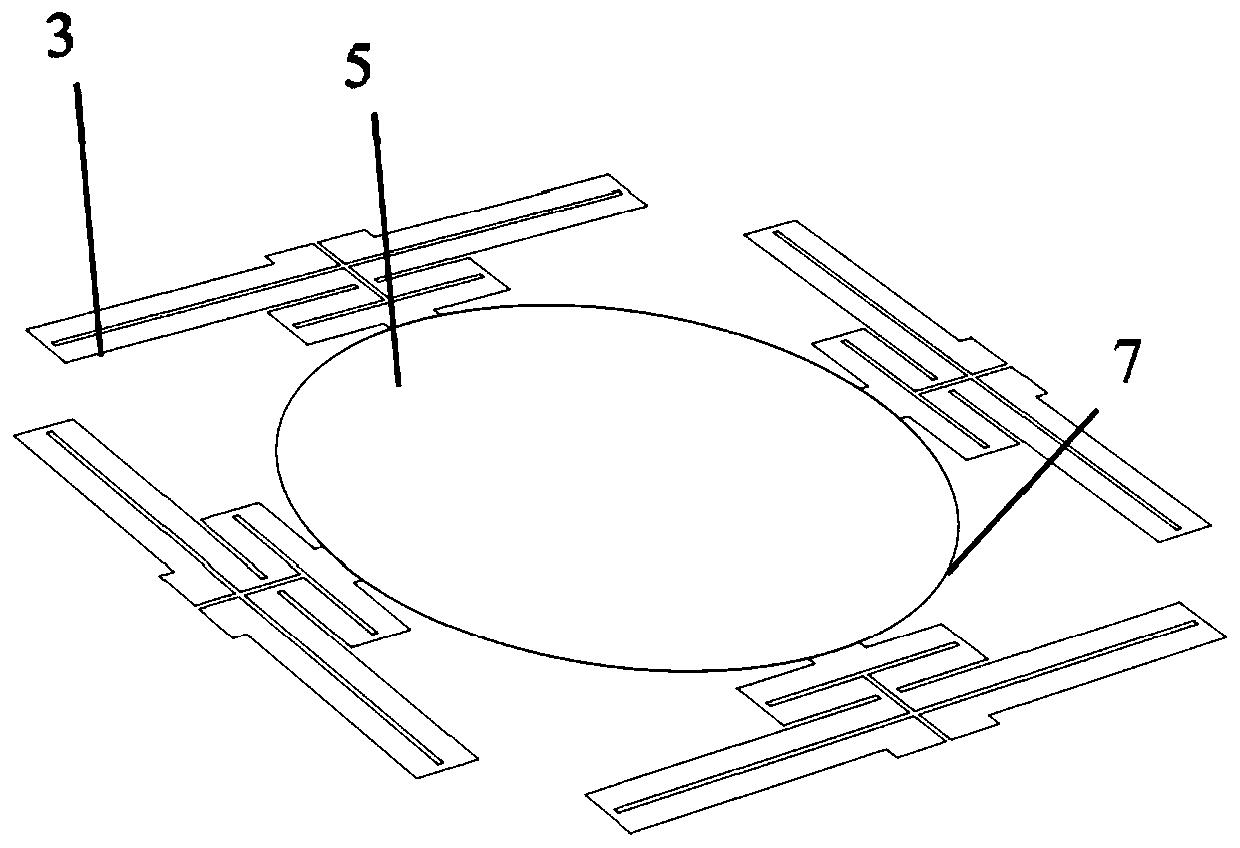

[0033] as attached figure 1 As shown, the present invention provides a thermally driven deformable micromirror. The micromirror is made up of a lens 4, an electrode 2, a beam 3 and a silicon structural frame 1, and four beams 3 support the circular lens 4 in the air on the silicon structure. The center of the structural frame 1, as attached figure 2 As shown, the lens 4 is divided into three layers from top to bottom, which are aluminum reflective layer 5, silicon dioxide layer 6 and silicon layer 7, as shown in the attached image 3 and 4 As shown, the silicon layer 7 of the beam 3 and the lens 4 is integrally formed of the same material, the silicon structure frame 1 and the beam 3 are insulated by a silicon dioxide layer 6, and the electrode 2 is arranged on the surface of the silicon structure frame 1 and the support The beam 3 is connected, and af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com