Connection structure of connection end of component and connection terminal

A connection structure and terminal button technology, which is applied in connection, electrical components, clamping/spring connection, etc., can solve the problems of insufficient stability, false welding at the welding place, separation from the base material, etc., and achieve a highly stable working state, The effect of prolonging the service life and saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

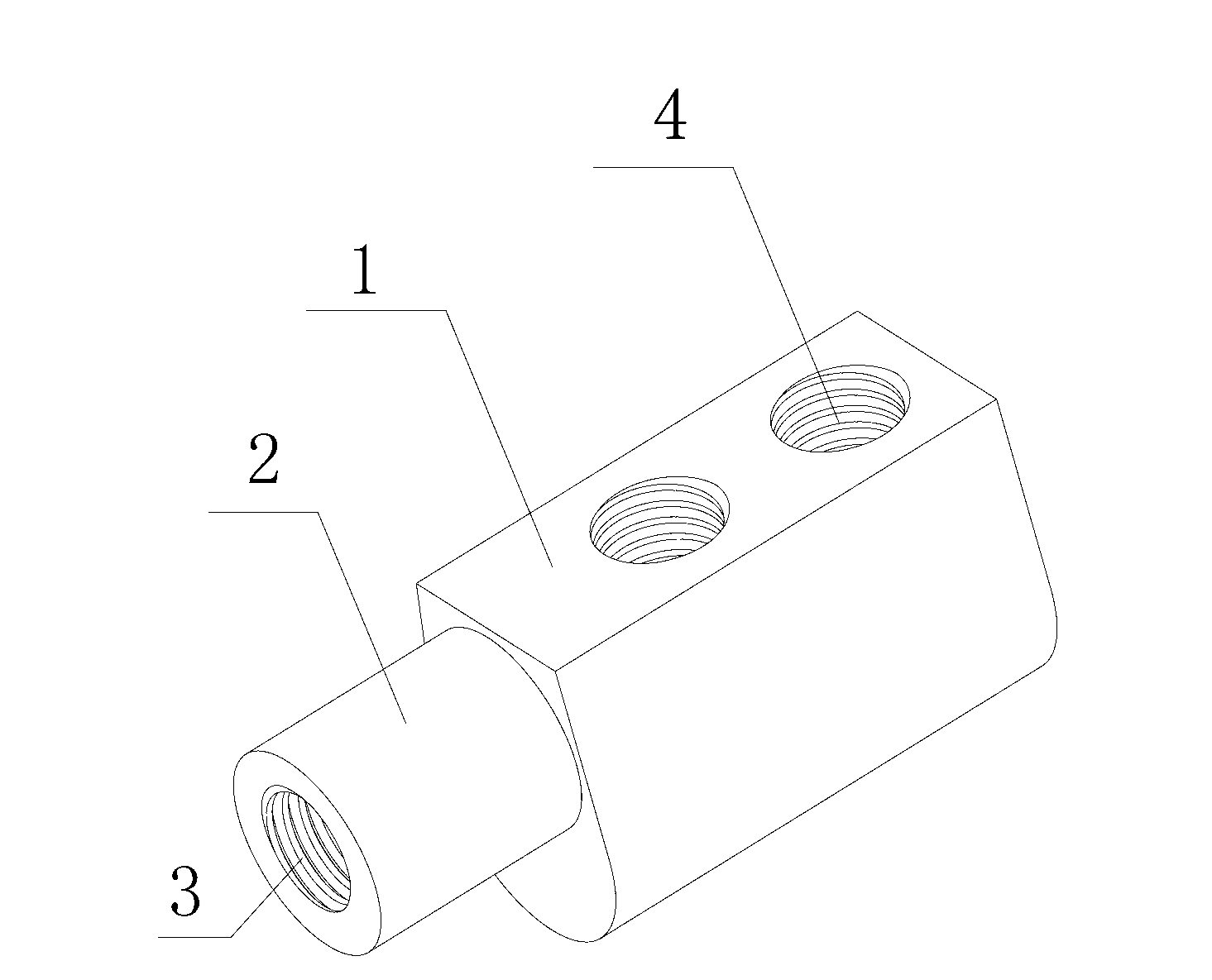

[0029] figure 1 , figure 2 As shown in , the axial end of the terminal button 1 is provided with a cylindrical column 2, and the center of the cylindrical column 2 is provided with a connecting hole 3, and the inner wall of the connecting hole 3 is provided with a radial groove, and the other axial end of the terminal button 1 One end is provided with a wiring hole 5 for external power input and output of the instrument, and a screw hole 4 is provided in the radial direction of the input and output wiring hole 5. The screw hole 4 is used to fix the external power input and output lines with screws. The connection hole 3 and the wiring hole The two holes of 5 are not connected to each other. Technically, the air outside the meter is blocked from entering the inside of the meter, which corrodes the internal components and prolongs the service life of the meter.

Embodiment 2

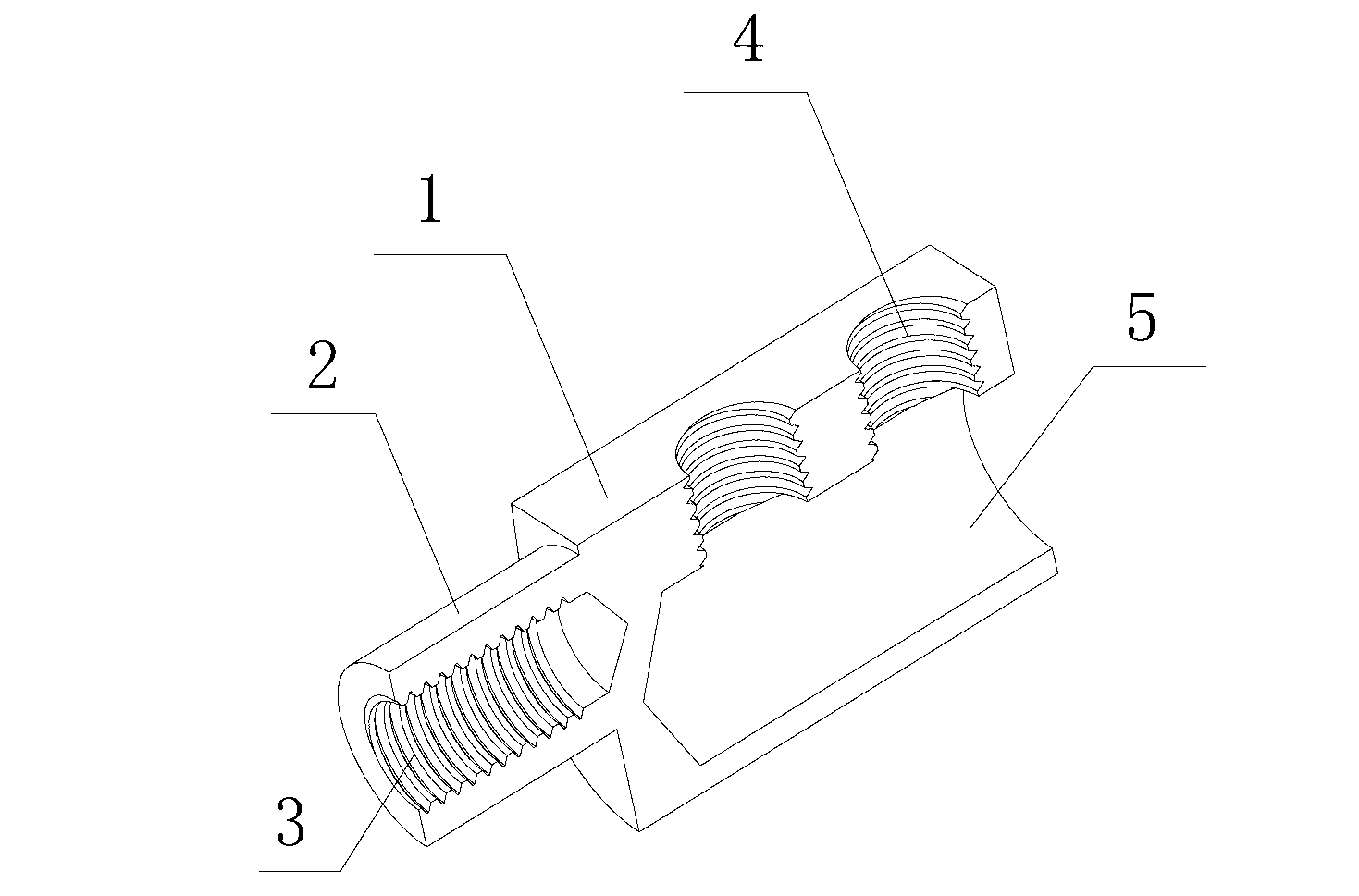

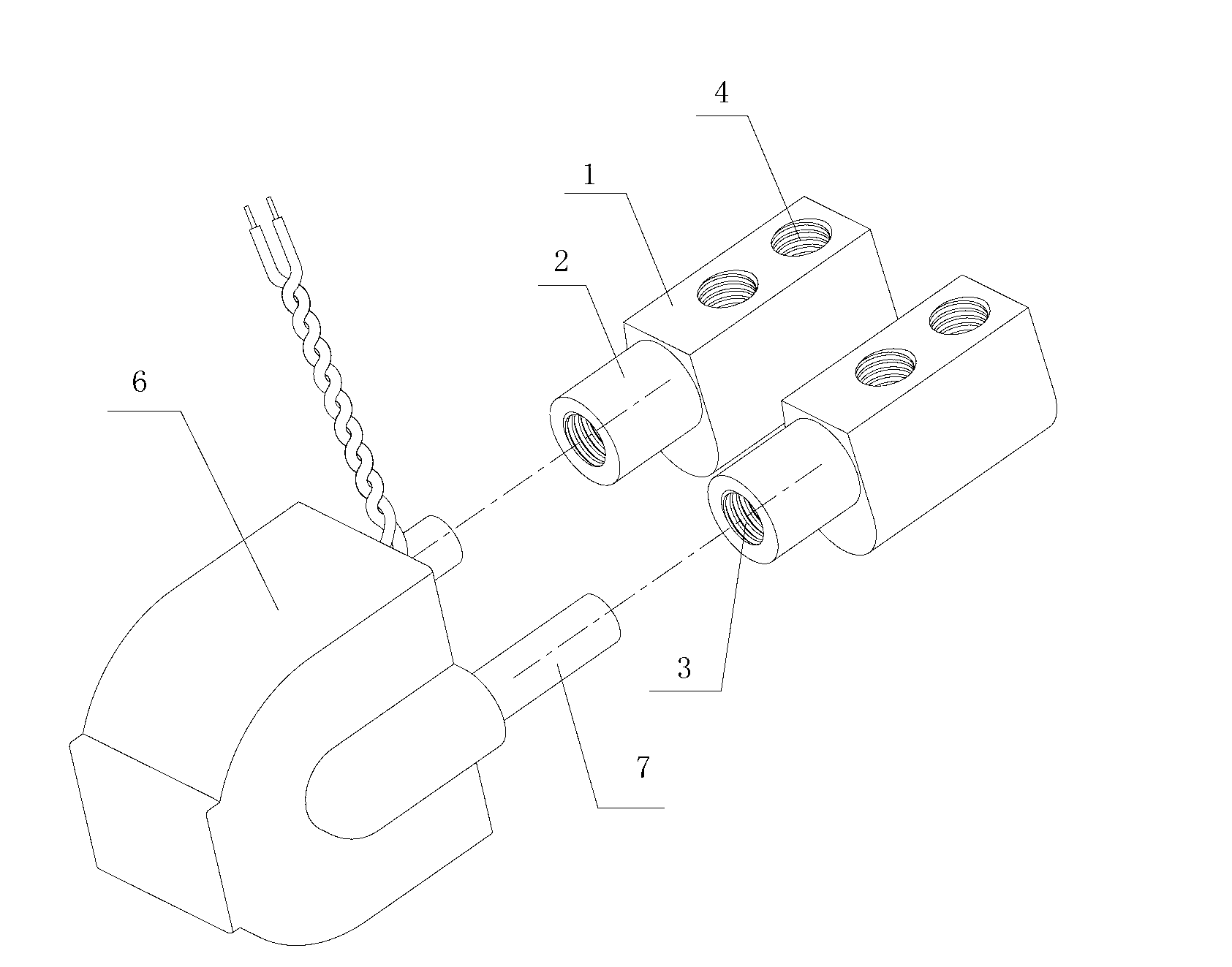

[0031] image 3 , Figure 4 , Figure 5 , Figure 6 In the shown embodiment, the connection terminal copper rod 7 of the device transformer 6 is inserted into the center of the cylindrical column 2 of the terminal button 1, and the connection hole 3 matching the connection terminal copper rod 7 of the device transformer 6 is provided. , use a press or a hydraulic press to press or hydraulically press the cylindrical column 2 of the terminal button 1, so that the material of the cylindrical column 2 is extruded and extended into the connecting hole 3, so that the cylindrical column 2 forms a hexagonal column 8 shape, and the connection The end copper rod 7 and the connection hole 3 are tightly attached to each other. Due to the stable and reliable mechanical pressing, the contact resistance is low; at the same time, after the connection hole 3 is mechanically pressed into the shape of the hexagonal column 8 by the cylindrical column 2, the connection hole 3 has become a spec...

Embodiment 3

[0034] Figure 7 , Figure 8 , Figure 9 , Figure 10 In the shown embodiment, the connecting end of the device transformer 6 and the self-holding relay 9 is inserted into the center of the cylindrical column 2 of the terminal button 1 with multi-strand flexible wires 10, and the device transformer 6, self-holding relay In the matching connecting hole 3 of the multi-strand flexible wire 10 at the connecting end of 9, press or hydraulically press or hydraulically press the cylindrical post 2 of the terminal button 1, so that the material of the cylindrical post 2 flows toward the connecting hole 3 Inner extruding extension causes cylindrical column 2 to form polygonal column 11 shape; The material is more evenly extruded and extended into the connecting hole 3, so that the multi-strand flexible wire 10 at the connecting end of the device is squeezed tightly and closely attached to the connecting hole 3; thereby further reducing the contact between the two Resistance is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com