Pipeline bus and detachable bus unit of pipeline bus

A busbar and pipeline technology, applied in the field of detachable busbar units, can solve the problems of high maintenance cost, low disassembly efficiency, inconvenient disassembly of the busbar unit, etc., and achieve the effects of convenient disassembly, convenient disassembly, and improved disassembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation of the pipeline busbar and the detachable busbar unit in the present invention will now be described in conjunction with the accompanying drawings.

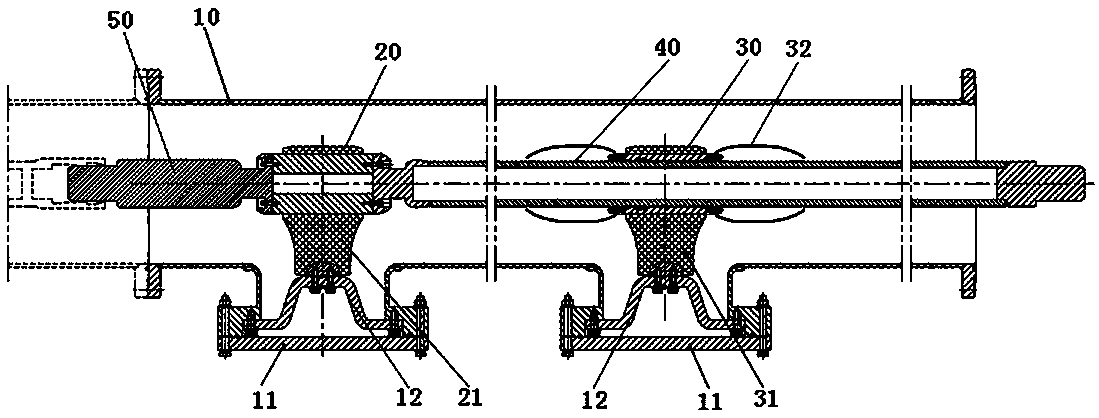

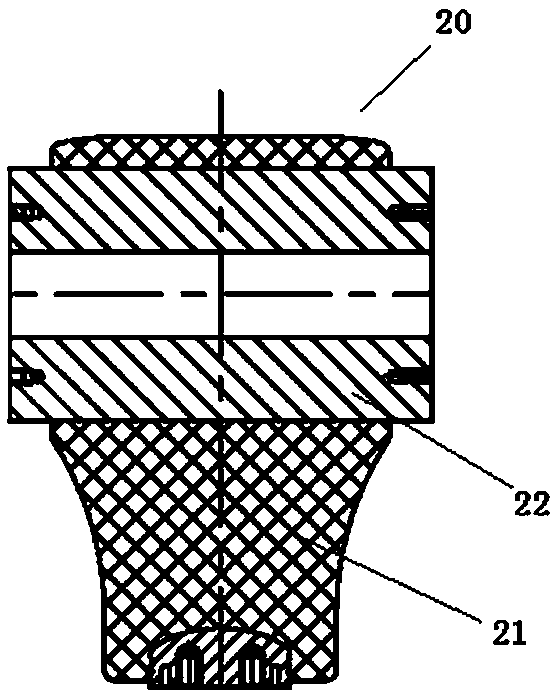

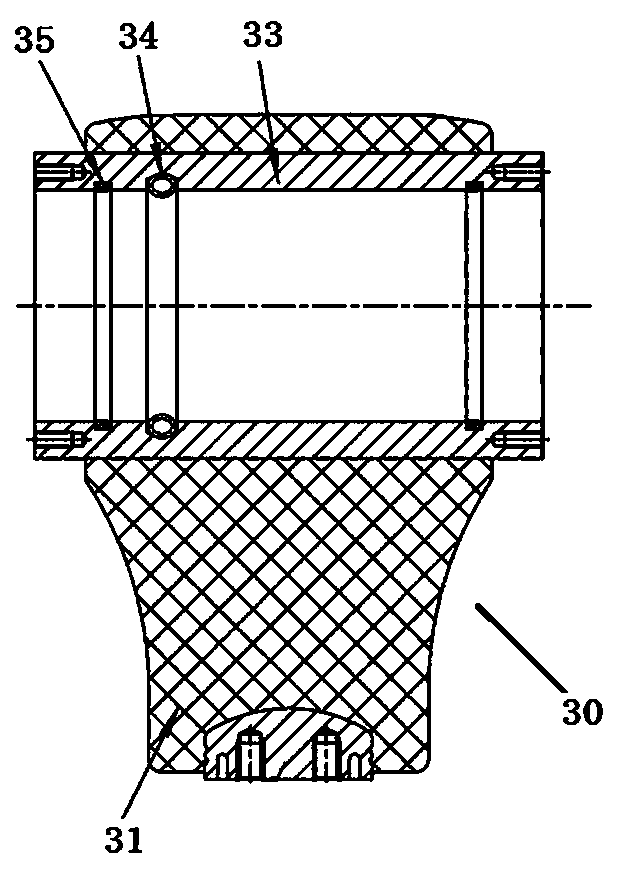

[0046] Such as figure 1 As shown, it is an embodiment of the pipeline busbar in the present invention: the pipeline busbar is formed by butt jointing of multiple busbar units, and a detachable busbar unit is also included in the pipeline busbar, and the detachable busbar unit includes a cylinder body 10 and a The conductive rod includes an adapter 50 and a conductive connecting rod 40. An insulator for supporting the conductive rod is arranged in the cylinder body 10, and the insulator is further divided into a fixed support insulator 20 and a movable support insulator 30. Both the fixed support insulator 20 and the movable support insulator 30 are single-pillar insulators, that is, they have a leg, the bottom end is a fixed end for fixed connection with the cylinder 10, and the top end is a con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com