Test leakage machine plugging assembly

A leak tester and component technology, applied in the direction of using liquid/vacuum for liquid tightness measurement, etc., can solve the problems of misjudging products as qualified products, poor sealing, leakage, etc., to improve accuracy and easy processing , the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

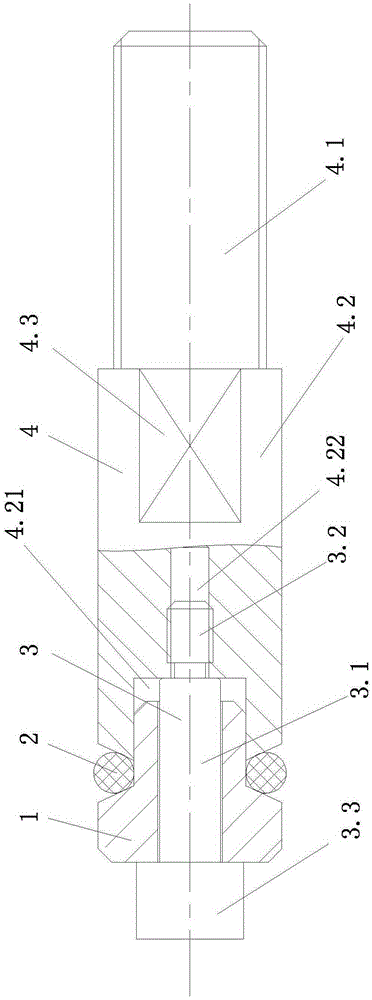

[0014] Such as figure 1 As shown, the present invention includes a movable casing 1, a sealing ring 2, a movable casing casing rod 3 and a fixed rod 4; the movable casing casing rod 3 includes a casing rod section 3.1, and the two ends of the casing rod section 3.1 are respectively screw sections 3.2 and wrench means 3.3, the diameter of sleeve rod section 3.1 is larger than the diameter of screw rod section 3.2 and smaller than the diameter of wrench means 3.3; one end of the fixed rod 4 is the fixed rod installation part 4.1, and the other end of the fixed rod is the movable sleeve connection part 4.2 , the diameter of the fixed rod mounting part 4.1 is smaller than the diameter of the movable casing connecting part 4.2, the movable casing connecting part 4.2 is provided with a movable casing connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com