An electric discharge machine tool for inner cavity treatment of metal products

A technology for EDM machine tools and metal products, applied in metal processing equipment, manufacturing tools, electrode manufacturing, etc., can solve the problems affecting processing efficiency and processing quality, difficulty in discharging electrical corrosion products, and processing size changes, and achieve stable processing. Reliable, improving the efficiency of electro-erosion processing, and the effect of reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

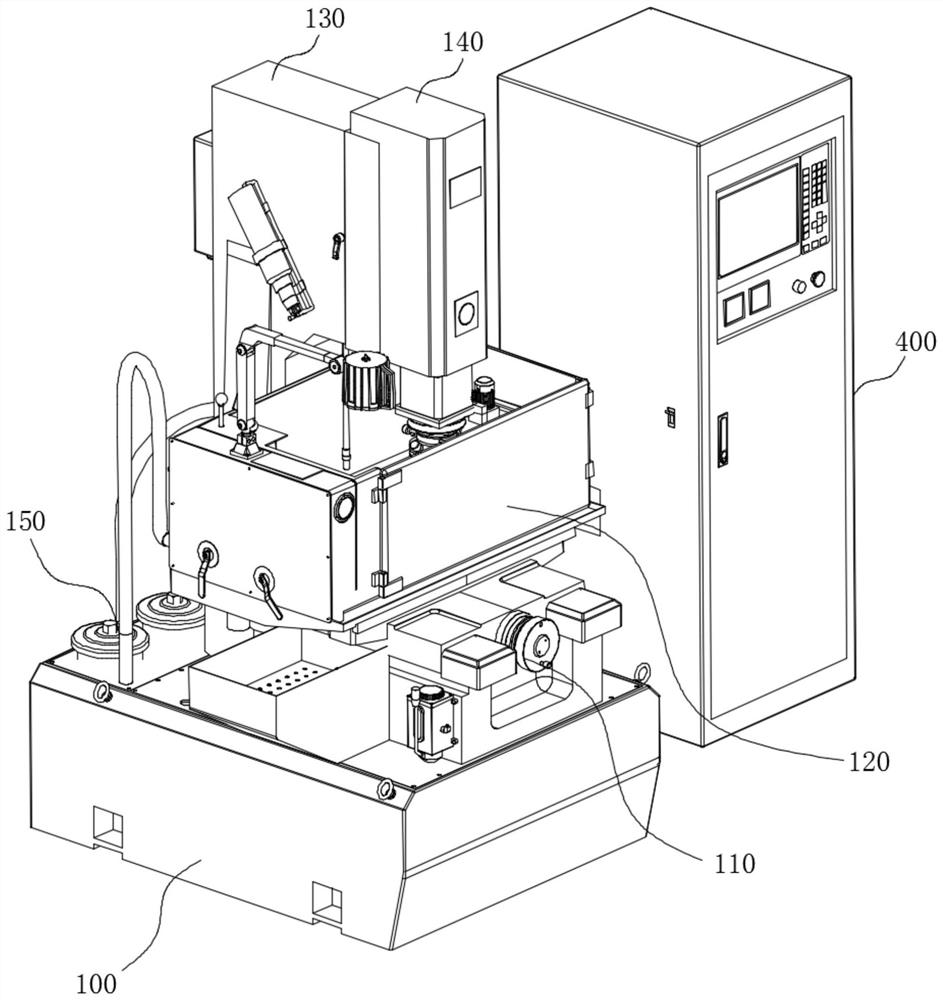

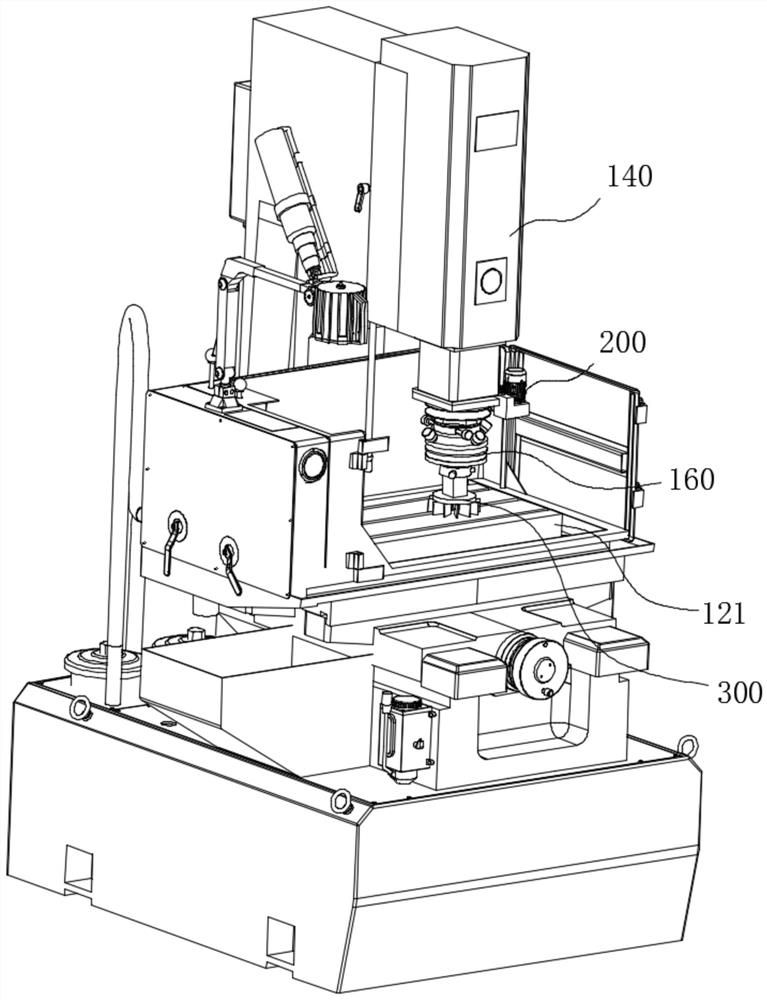

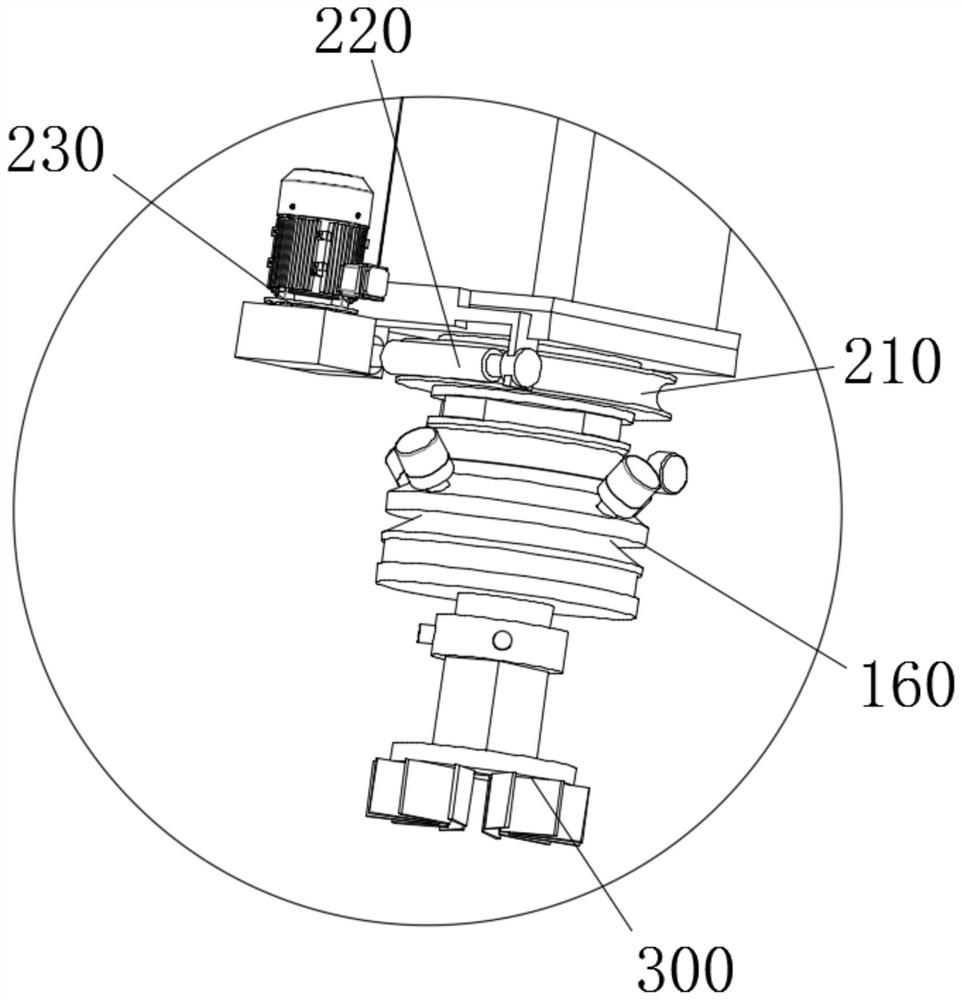

[0042] Reference attached figure 1 and figure 2 , in this embodiment, a kind of electric discharge machine tool for internal cavity treatment of metal products is proposed, which includes a bed 100 and a column 130. The table 110 is arranged correspondingly. The workbench 110 is provided with a water tank 120 , the bottom of the water tank 120 is provided with a fixture 121 for clamping the workpiece, the water tank 120 is connected to the working fluid circulation system 150 , and the lower end of the spindle head 140 is equipped with an electrode chuck 160 ;

[0043] The tool electrode 300 is installed on the electrode chuck 160, and the cavity structure of the tool electrode 300 and the workpiece 500 are matched. The long direction is consistent with the height direction of the machine tool. The various shaped grooves 510 are distributed in a circular array around the center line of the cavity. The groove width of the shaped grooves 510 gradually increases along the dire...

Embodiment 2

[0056] In this embodiment, a processing method for machining a special-shaped groove of a metal workpiece cavity using an electric discharge machine tool in Embodiment 1 is proposed, including the following steps:

[0057] Step 1: using graphite material to prepare the tool electrode 300 matching the cavity shaped groove 510 of the workpiece 500;

[0058] Step 2: horizontally position and clamp the workpiece 500 on the fixture 121;

[0059] Step 3: install the tool electrode 300 on the electrode holder 160;

[0060] Step 4: Start the EDM machine tool, the tool electrode 300 and the workpiece 500 are aligned. After the two are aligned, the spindle head 140 drives the tool electrode 300 to descend gradually, and the tool electrode 300 discharges and erodes the cavity side wall of the workpiece 500 and the water outlet hole 311 The working fluid is discharged in the middle, and the working fluid flushes out the electro-corrosion products;

[0061] Step 5: When the tool electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com