Laser hole processing system and method with processing and real-time detection capability

A real-time detection and processing system technology, applied in the field of micro-nano detection, can solve the problems of complex structure of detection equipment and high detection cost, and achieve the effect of compact and simple structure, improved signal-to-noise ratio, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

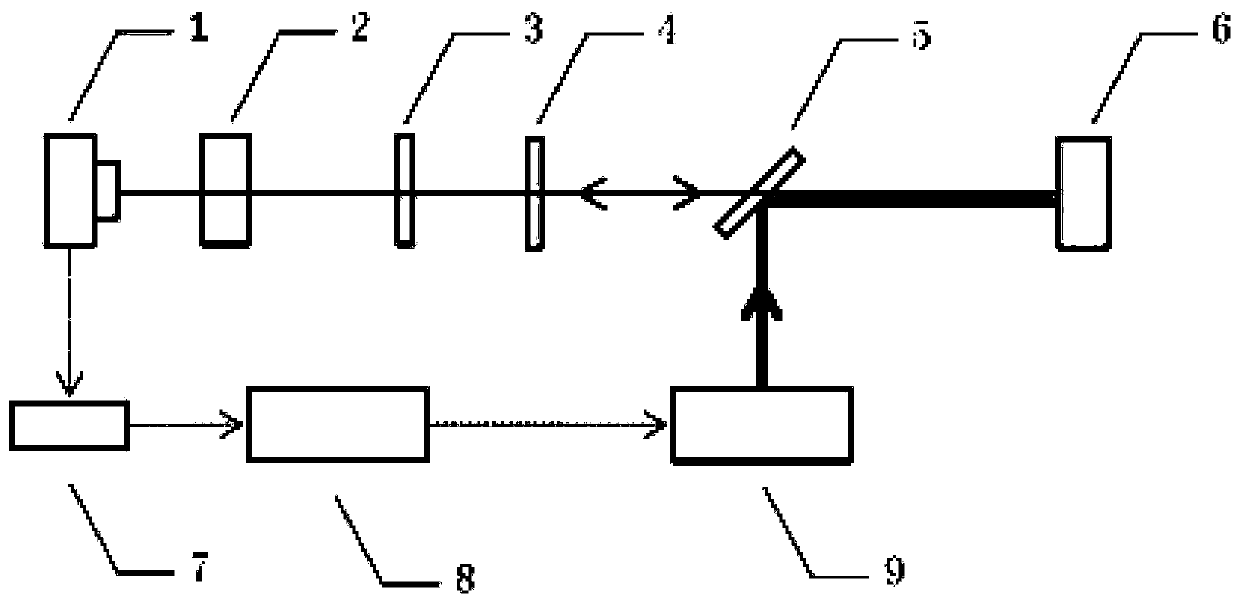

[0041] see figure 1 , a laser hole processing system with both processing and real-time detection capabilities, including a semiconductor laser 1, a beam collimation unit 2, a polarizer 3, a quarter wave plate 4, a dichroic beam splitter 5, a data acquisition unit 7, Data processing unit 8 and laser processing equipment 9; It should be noted that: laser processing equipment 8 adopts existing conventional laser processing equipment, and its main components include laser, laser focusing unit, parameter adjustment and motion control unit. In addition, the laser here may be a continuous laser, a pulse laser or an ultrashort pulse laser. In this embodiment, an ultrashort pulse laser is selected. The beam collimation unit 2 here is a fast and slow axis collimation system;

[0042] A beam collimation unit 2, a polarizer 3, a quarter-wave plate 4, a dichroic beam splitter 5, and a workpiece 6 are sequentially arranged on the probe beam emitted by the semiconductor laser 1; the polar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com