Large thin-wall frame type precision casting part clamping device and clamping method

A clamping device and frame-type technology, applied in positioning devices, metal processing machinery parts, clamping, etc., can solve problems such as difficulty in ensuring the coordination relationship of parts, affecting appearance and performance, and stress concentration of parts, so as to reduce processing vibration, The effect of reducing the time occupied by the machine tool and reducing the vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

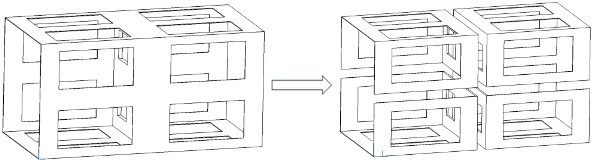

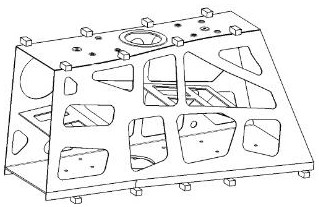

[0068] A large thin-walled frame type precision casting parts clamping device, the parts 7 are placed on the tooling backing plate 6, such as figure 2 As shown, the upper and lower surfaces of the part 7 are respectively provided with double rows of semi-suspended bosses 1 along the length of the parallel sides; Figure 6 As shown, the open end area of the part 7 is provided with an open end area pressing device 2, and the upper surface of the part 7 is provided with a top surface boss pressing device 4; the bottom of the part 7 is provided with There is a pressing device 3 for positioning bosses on the bottom surface; a pressing device 5 in the middle web hole area is provided in the middle of the part 7 for double-sided pressing of the web of the part 7 .

[0069] The present invention is provided with upper and lower double-sided, left-right double-sided bosses 1, which can ensure that there are pressing connection devices on the upper and lower surfaces of the casting, ...

Embodiment 2

[0071] This embodiment is optimized on the basis of embodiment 1, such as Figure 7 , Figure 8 As shown, the open-end area pressing device 2 includes a mounting base and an upper pressing device and a lower pressing device arranged on the mounting base, and the upper pressing device and the lower pressing device are fixedly clamped Part 7; also includes a support 8 and a bracket 11, the top of the support 11 is connected to the mounting seat, and the bottom is connected to the support 8 through a bolt 10, and the support 8 is detachably connected to the tooling backing plate 6.

[0072] Further, as Figure 7 , Figure 8 As shown, the upper end pressing device includes a pressing plate 13, a stud 16, a guide screw 12, and a nut 14, and the stud 16 and the guide screw 12 are arranged in parallel on the mounting seat, and the pressing plate 13 is connected with the stud 16 and the guide respectively. The screw 12 is slidingly connected, and the stud 16 passes through the pres...

Embodiment 3

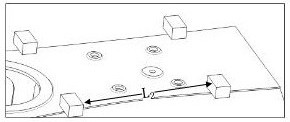

[0076] This embodiment is optimized on the basis of embodiment 1 or 2, as Figure 14-Figure 18 As shown, the pressing device 5 in the middle web hole area includes a pillar 27, an adjusting nut 26, a washer 25, and a circular pressure plate 24. The pillar 27 is arranged inside the part 7, and the bottom of the pillar 27 passes through the part 7 And be connected with tool backing plate 6, and the top passes through the web of part 7 upwards and is connected with circular pressure plate 24, and screw 9 passes through circular pressure plate 24 and is threaded with the top of pillar 27; A washer 25 and an adjusting nut 26 are sequentially arranged on the pillar 27 from top to bottom. The washer 25 is slidably installed on the pillar 27 , and the adjusting nut 26 is screwed to the pillar 27 .

[0077] There are large-diameter holes in the upper and lower middle areas of the casting, which belong to the weakest rigidity of the entire casting. The present invention is suitable for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com