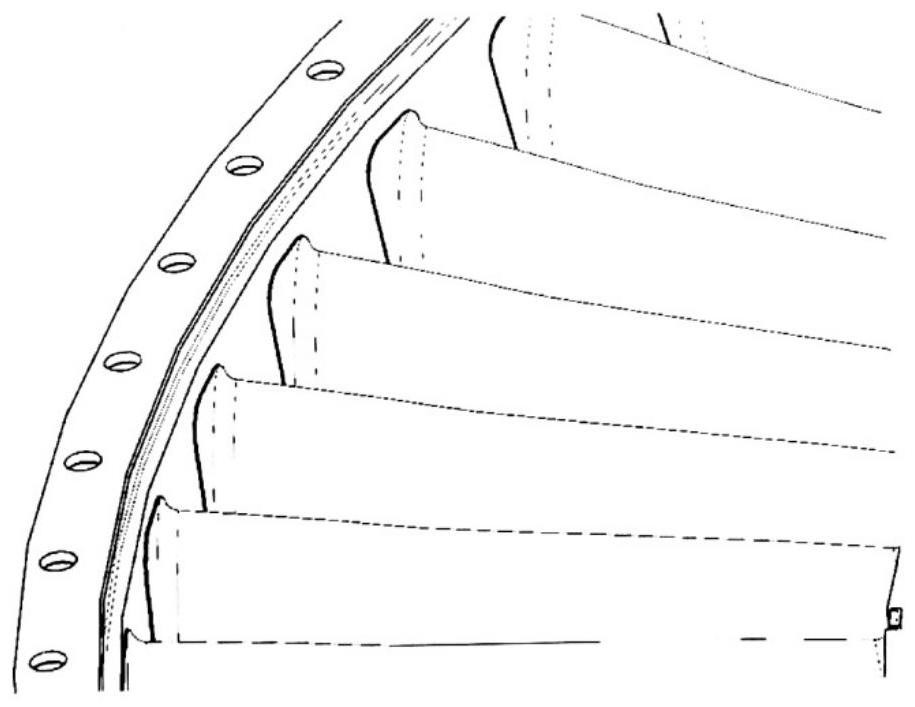

Mounting edge repairing method

A technology of parts installation and turning processing, which is applied in the field of installation and repair, and can solve problems affecting production and delivery tasks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

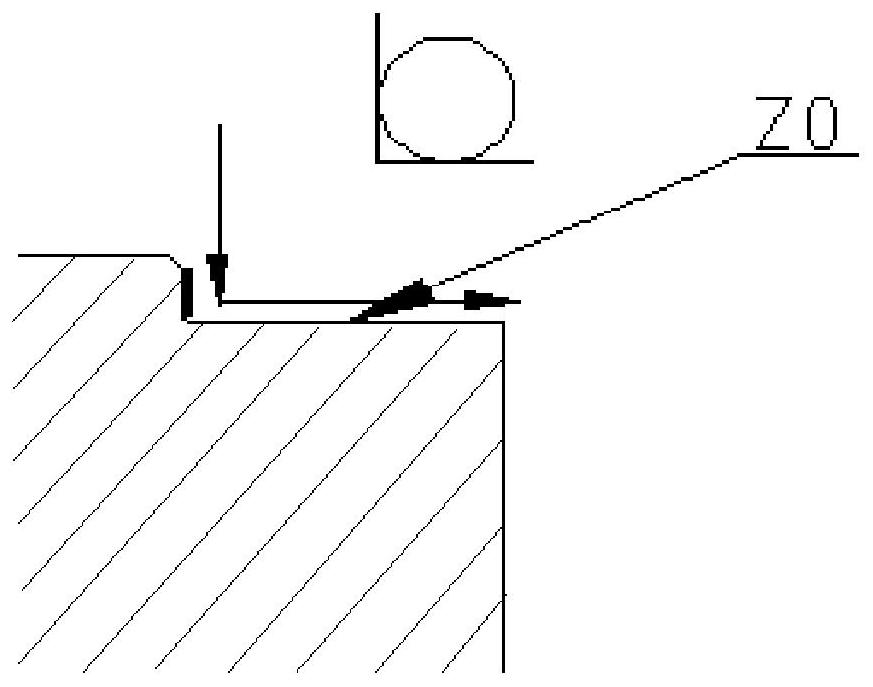

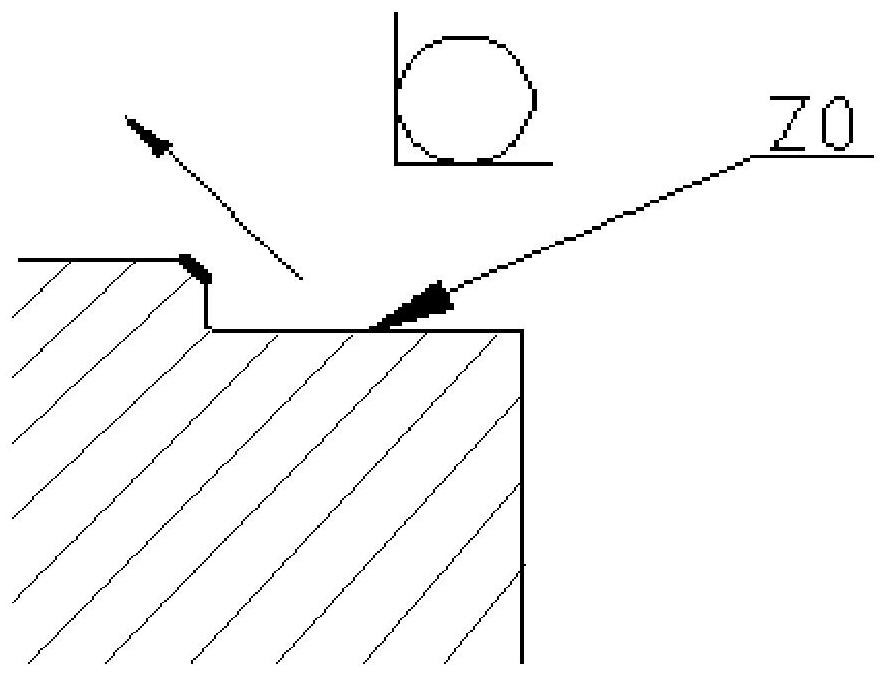

[0031] KF306 coating is an emerging wear-resistant material, which is widely used in wear-resistant coatings of aviation parts. In order to save a large number of titanium alloy TC4 material fan casing parts, on the basis of comprehensive analysis, heat resistance, wear resistance, hardness and other properties of titanium alloy materials, the repair process of spraying KF306 coating on the fan casing is adopted. Due to the high hardness and high brittleness of the KF306 coating, it is easy to break and fall off during the turning process. Therefore, after spraying the KF306 coating on the inner seam of the installation side, the initial repair stage can only be processed by grinding. Grinding machine equipment is limited, and the grinding cycle is long. It takes two days to grind and install a part. On the one hand, it takes up a lot of grinding machine equipment, and on the other hand, it seriously affects production efficiency and delivery nodes. The most ideal processing m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com