Workpiece painting processing equipment

A technology for processing equipment and workpieces, which is applied in the field of workpiece painting processing equipment, can solve problems such as health injuries of operators, achieve the effects of improving processing efficiency, automating the drying process, and saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

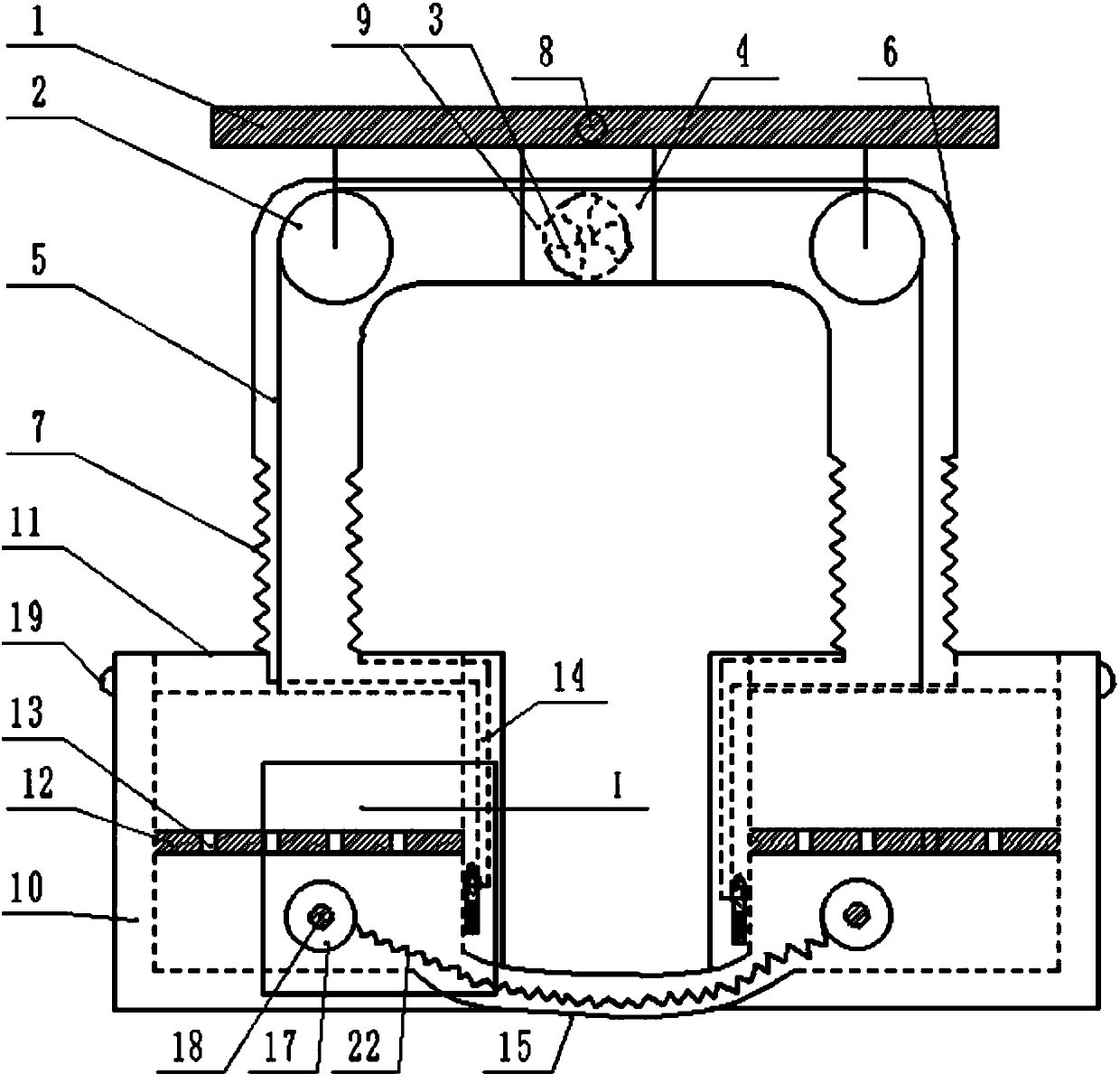

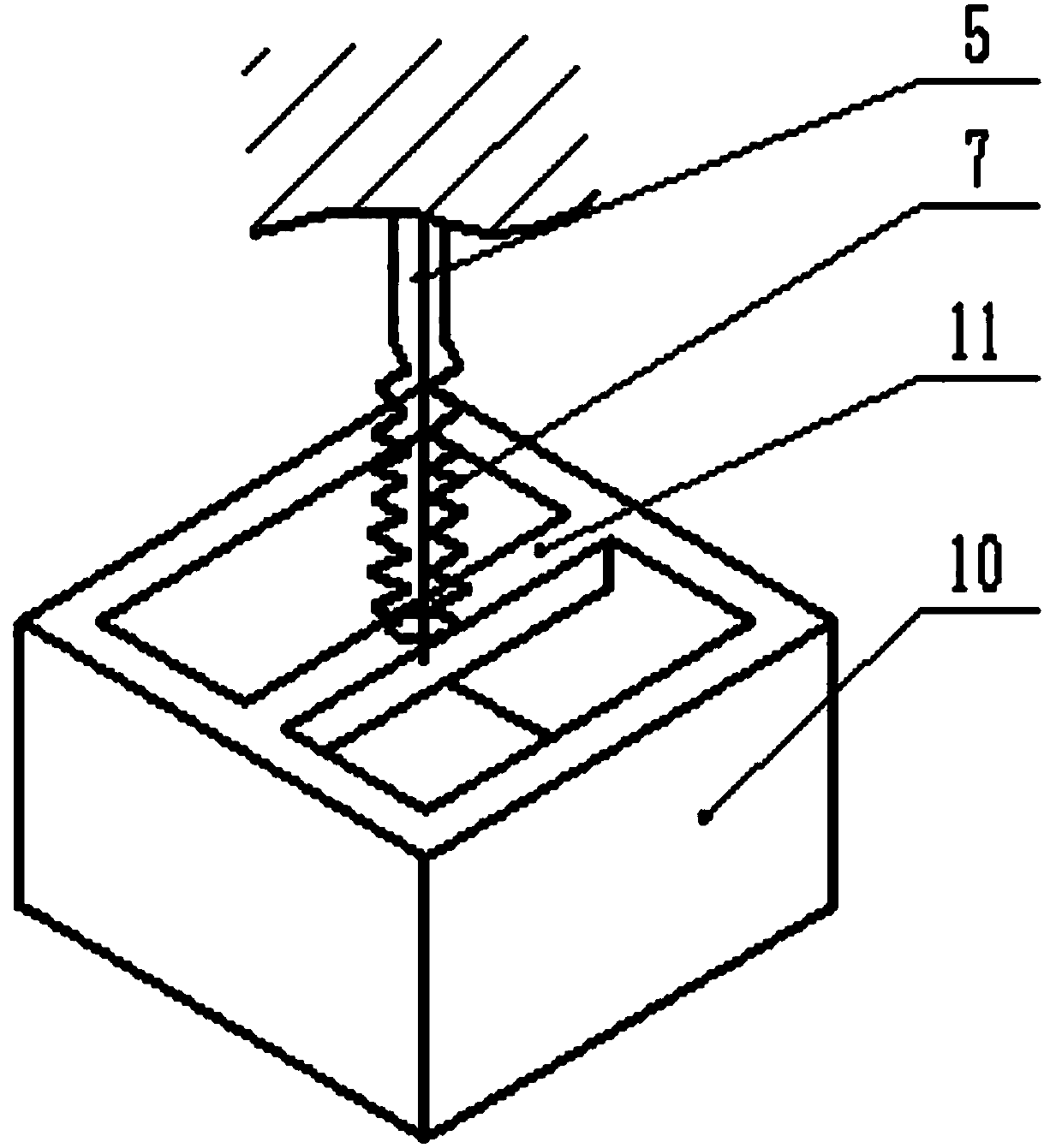

[0021] A workpiece painting processing equipment includes a control mechanism and an execution mechanism, and the control mechanism is located above the execution mechanism. The control mechanism includes a beam 1, two fixed pulleys 2, a fan 3, a rotating motor 4, a chain 5, a ventilation cover 6, a ventilation hose 7 and a rotation motor switch 8. Such as figure 1 As shown, the rotary motor switch 8 is located on the beam 1, the rotary motor switch 8 is electrically connected to the rotary motor 4, the two fixed pulleys 2 are welded on the beam 1 through the pole, the rotary motor 4 is welded on the beam 1, and the rotary motor 4 is located at In the middle of the two fixed pulleys 2, the chain 5 is wound on the two fixed pulleys 2, and the two fixed pulleys 2 play the role of supporting and positioning the chain 5, and the rotating shaft of the rotating motor 4 is welded with a sprocket 9, and the sprocket 9 and the chain 5 mesh with each other . A fan 3 is welded coaxiall...

Embodiment 2

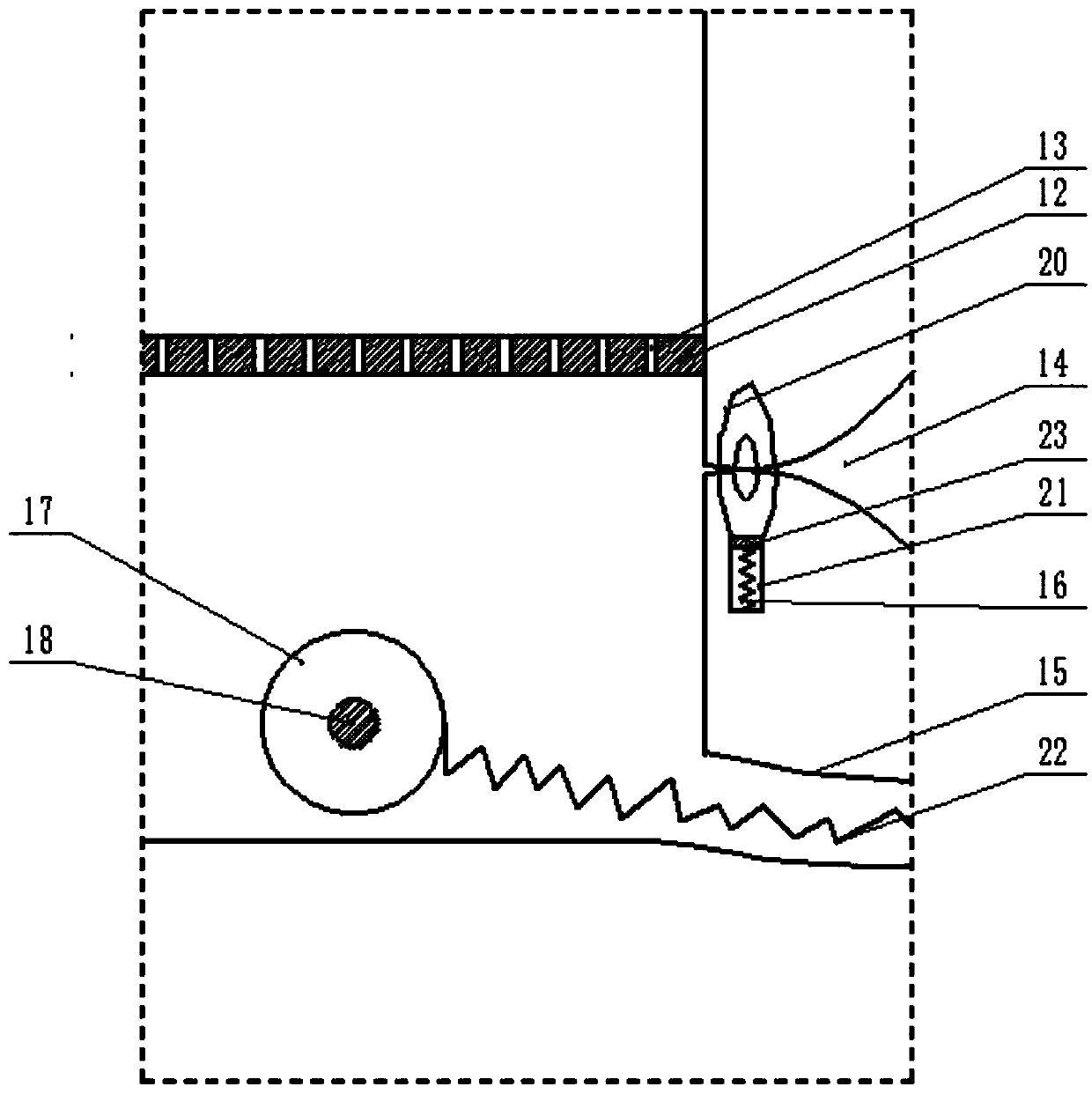

[0024] Such as Figure 5 Shown is a workpiece painting processing equipment, the difference between this workpiece painting processing equipment and the specific embodiment 1 is that the drying hose 14 of this solution communicates with the through hole 13 of the carrier plate 12 . In this solution, when the drying hose 14 is working, the wind force is directly delivered to the through hole 13, so that the wind force no longer flows into the working groove 10 below the bearing plate 12, but the wind force directly acts on the workpiece, avoiding excessive wind force waste, further improving the processing efficiency of workpiece painting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com