A scraper machine tail drum

A scraper and roller technology, which is applied to the field of the integrated tail roller of the scraper, can solve the problems that the mechanical performance is not stable and reliable, the processing of the tail roller is cumbersome, and the structural stability is poor, and the processing process is safe and reliable. Light, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

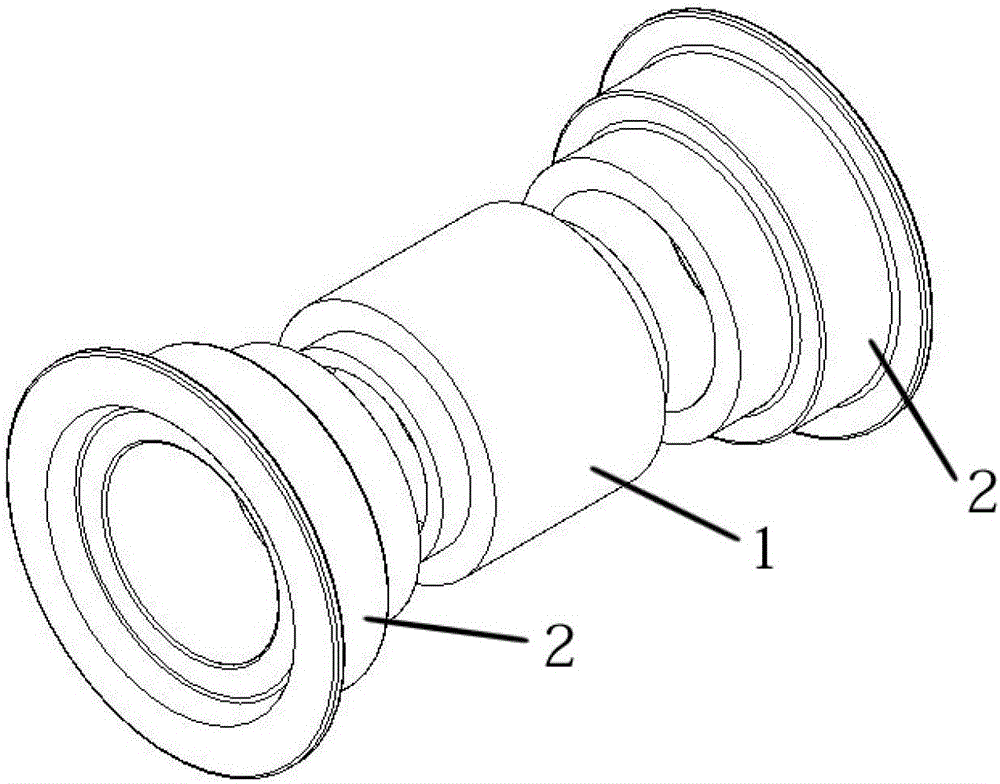

[0017] Such as image 3 , Figure 4 Shown is the tail drum of the scraper machine in the prior art, which is composed of a middle drum 1 and an outer drum 2. During processing, the middle drum 1 and the outer drum 2 need to be processed separately, and then assembled and welded together. Since the middle cylinder 1 and the outer cylinder 2 need to be well combined, the middle cylinder 1 or the outer cylinder 2 needs to have a corresponding joint shape, thus wasting materials and man-hours, and it is easy to increase the cost due to welding errors during processing. At the same time, since the materials used in the prior art are generally common iron alloys, which are prone to breakage and oxidation, the cost is thus increased.

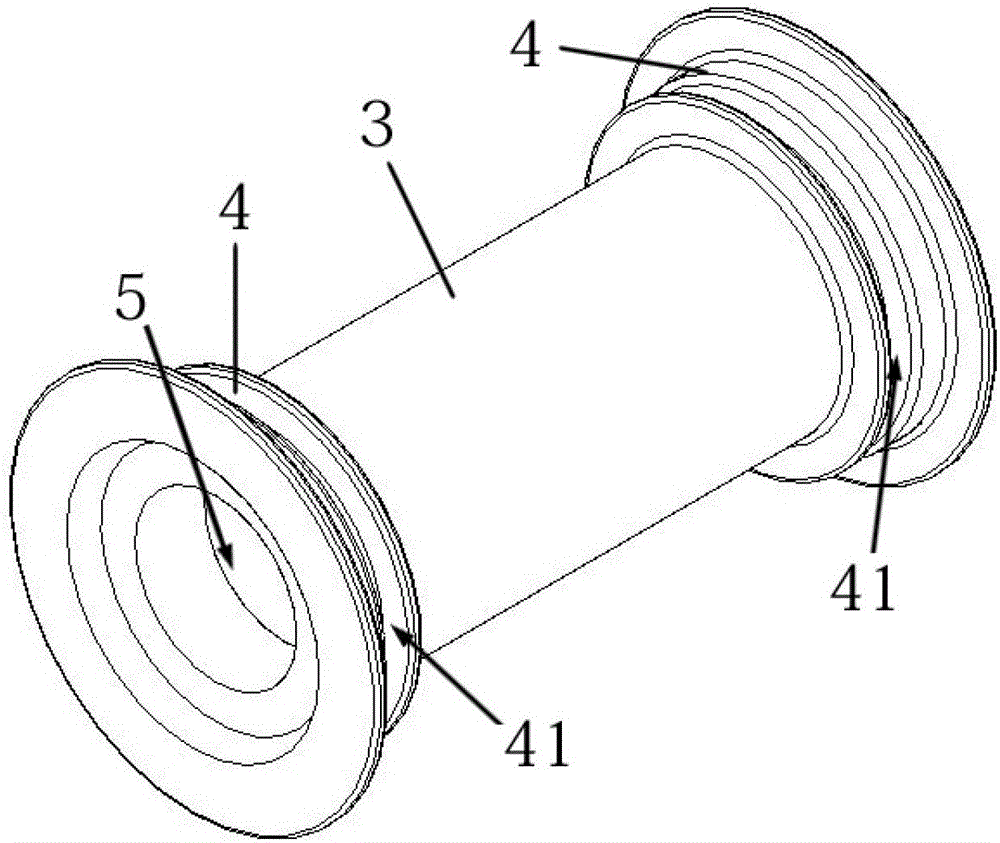

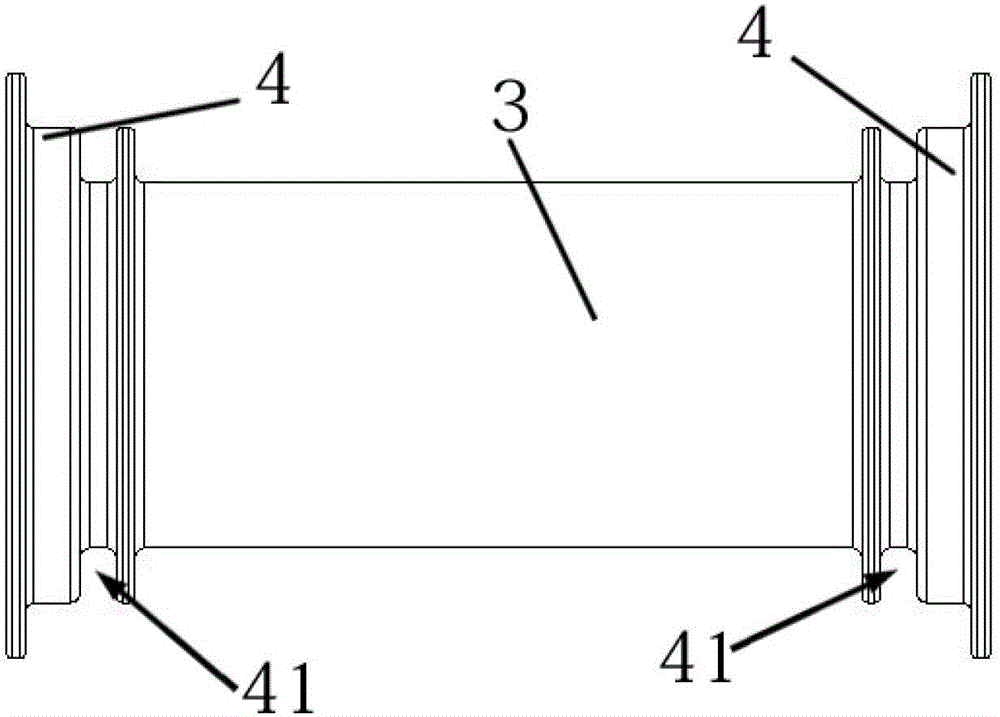

[0018] Such as figure 1 , figure 2 The tail drum of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com