Selective laser melting forming method for small-gap closed aluminum alloy impeller

A technology of laser selective melting and aluminum alloy impeller, which is applied in the directions of additive manufacturing, process efficiency improvement, additive processing, etc. problems, to achieve the effect of ensuring the consistency of the surface quality of the flow channel, improving the dimensional accuracy and shape accuracy, and improving the mechanical properties and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] Such as Figure 5 As shown, a small-gap closed-type aluminum alloy impeller laser selective melting forming method, the steps include:

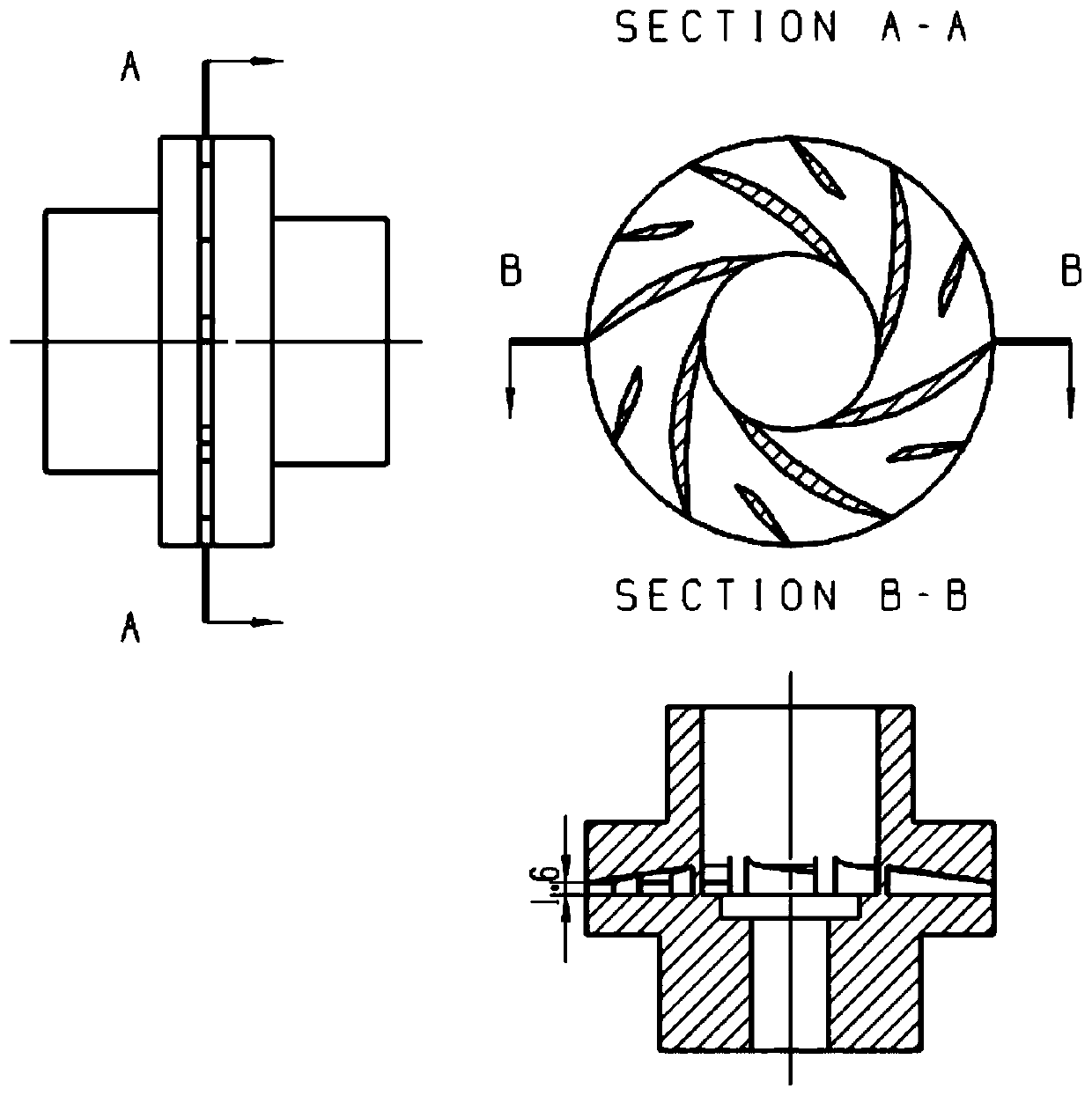

[0069] (1) The established three-dimensional model of the aluminum alloy impeller, such as figure 1 As shown, the diameter is 70mm, the height is 46mm, and the outlet size is 1.6mm;

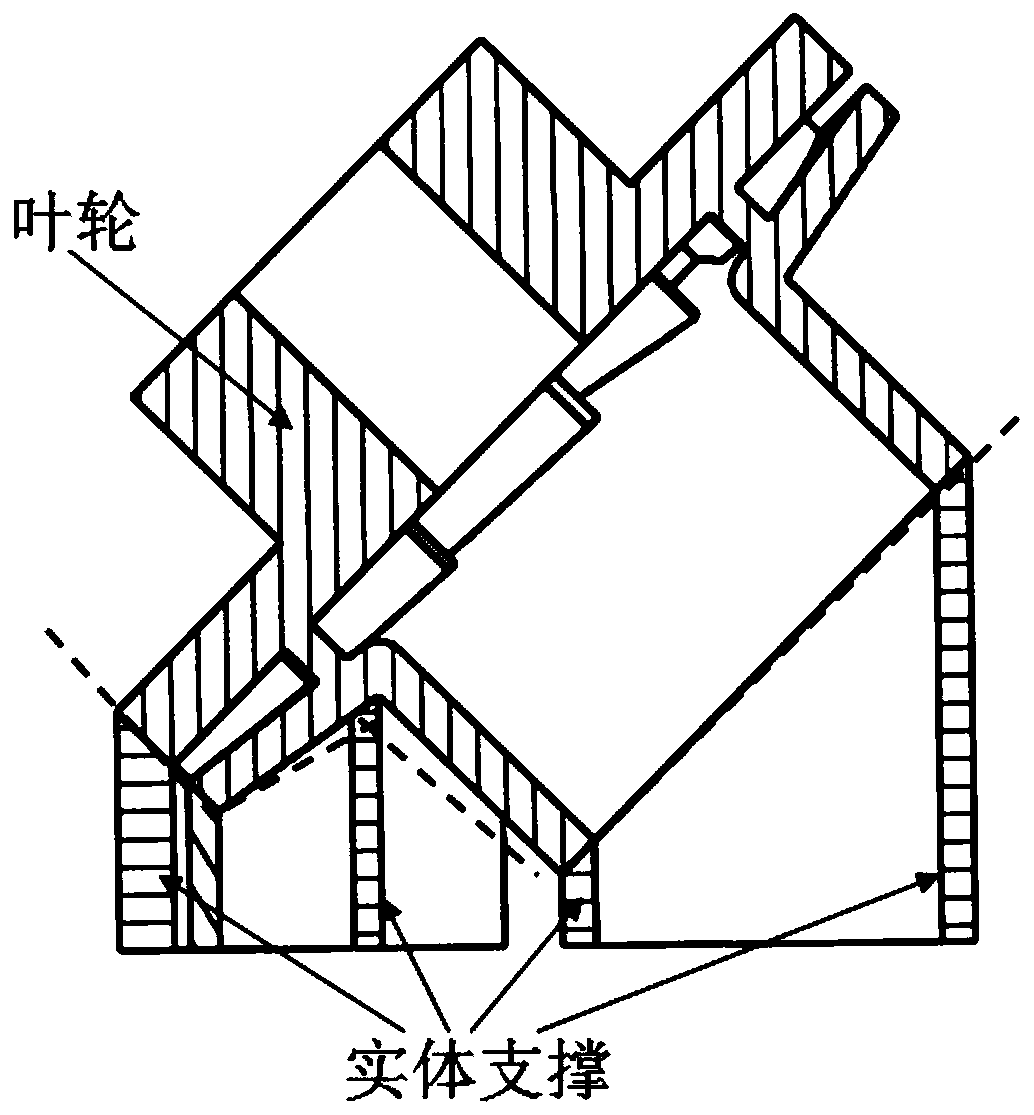

[0070] (2) The selected impeller forming direction, such as figure 2 shown.

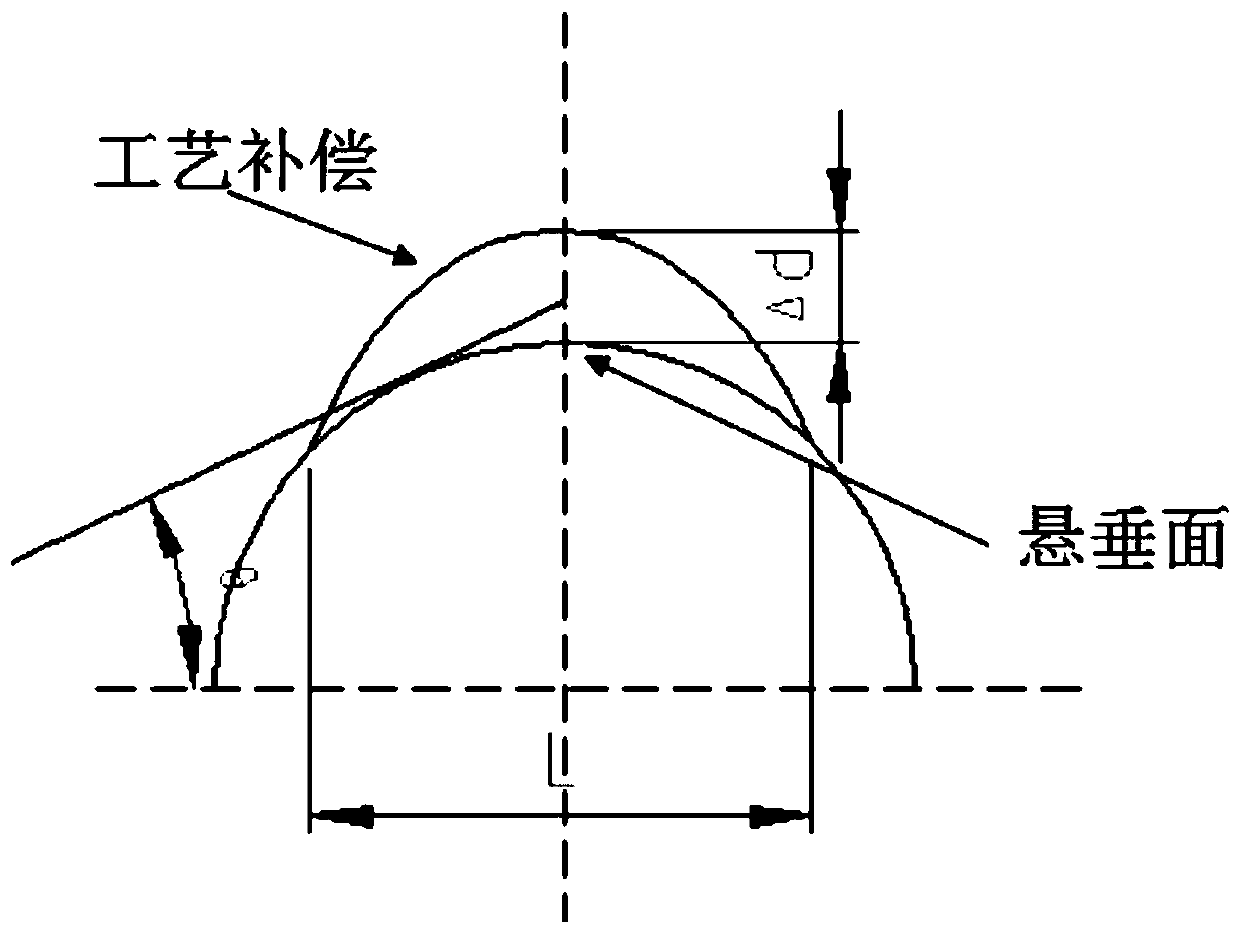

[0071] (3) Add process pre-compensation, the schematic diagram of process pre-compensation is as follows image 3 shown.

[0072] (4) The added support of the final model, including the hollow columnar support inside the impeller and the solid support at the lower part of the cover plate, the hollow columnar support is as follows Figure 4 shown.

[0073] (5) Adjust the position of the model with added support on the forming substrate platform, and then select the parameter package of AlSi10Mg aluminum alloy for subdivision processing. The process parameters of the impell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com