Metal film preparation method

A metal thin film and thin film technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of poor step integrity, corrosion damage to the surface of the substrate, incomplete corrosion of the surface coating or over-corrosion, etc. The structure is complete and clear, preventing impurities from remaining, and avoiding the effect of impurity residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

[0029] (1) Processing and surface treatment of nickel base material

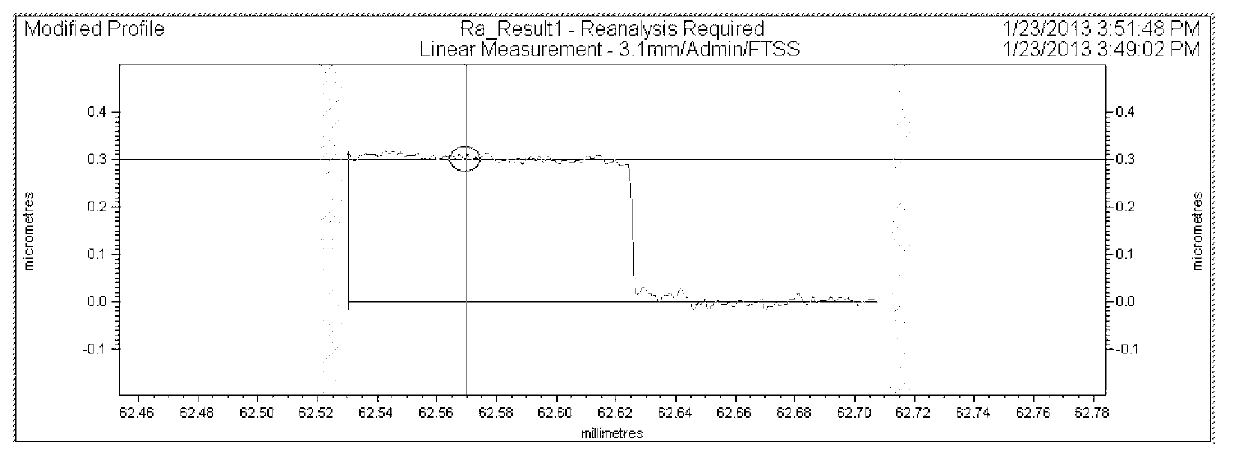

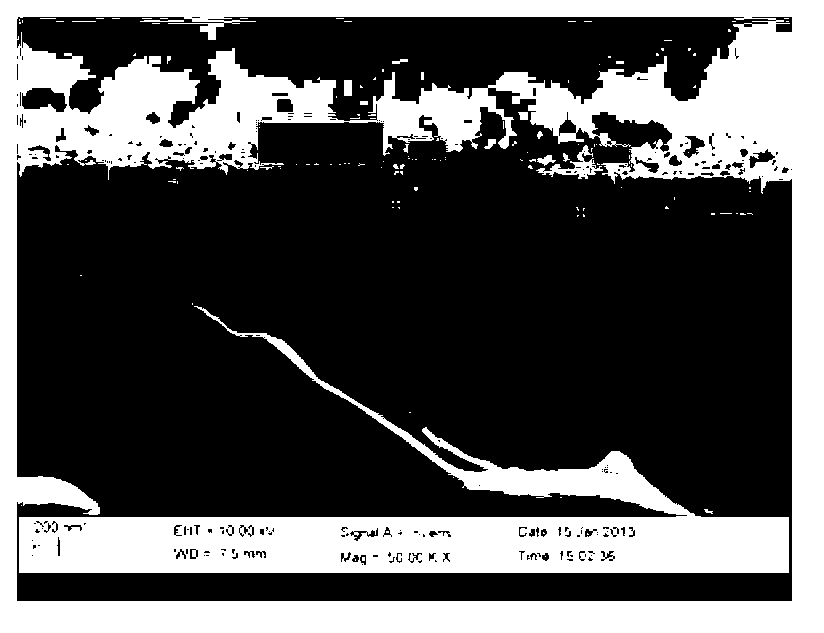

[0030] Wire-cut pure nickel block (nickel purity over 99.9%) into a 5mm×5mm×5mm cube matrix. Mount samples on a mounting machine with epoxy resin. Use 400#, 600#, 800#, 1000# and 1200# metallographic sandpaper for mechanical grinding, and then polish with flannelette. After cleaning the surface with absolute ethanol, use a roughness tester to check that the surface roughness of the nickel substrate is 0.017 μm. Remove the epoxy resin coating by hammering or squeezing, place the taken out nickel substrate in absolute ethanol for ultrasonic cleaning for 20 minutes, and then dry it for later use.

[0031] (2) Partial glue protection on the surface of nickel substrate

[0032] Apply an appropriate amount of conductive silver glue evenly on one side of the printing plate with a thickness of 1mm, and use the printing plate to print a linear silver glue on the center of the surface of the nickel substrate. After...

Embodiment 3~10

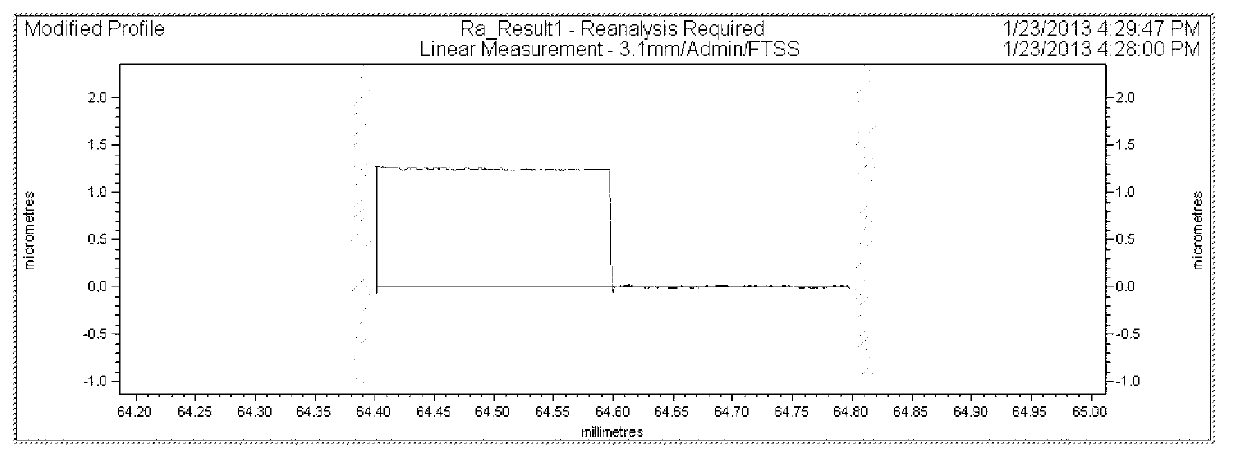

[0039] Cut the blocks in Table 1 into substrates of corresponding specifications. Mount samples on a mounting machine using bakelite powder. Use 400#, 600#, 800#, 1000# and 1200# metallographic sandpaper to manually grind, and then polish with flannelette, so that the surface roughness of the metal substrate is less than 0.02 μm. Remove the bakelite coating by hammering or squeezing, place the metal substrate in absolute ethanol for ultrasonic cleaning according to the time in Table 1, and then dry it for later use.

[0040] Apply the adhesive shown in Table 1 evenly on the surface of the substrate by brushing.

[0041] After the adhesive dries to form an adhesive layer, a metal film is plated on the surface of the metal substrate and the adhesive layer. Place the metal substrate in the magnetron sputtering coating device and use the metal target vacuum coating as shown in Table 1. During the coating process, the temperature of the substrate is kept at room temperature, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com