Polymer nanometer composite material and preparation method thereof

A nano-composite material and polymer technology, which is applied in the field of polymer nano-composite materials and their preparation, can solve the problems of affecting the performance uniformity of the composite material, uneven distribution of particles in the composite material, and reduction of the breakdown field strength of the composite material. Achieve excellent dielectric properties and performance stability, high dielectric constant and breakdown field strength, and improved dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1, preparation polymer nanocomposite material

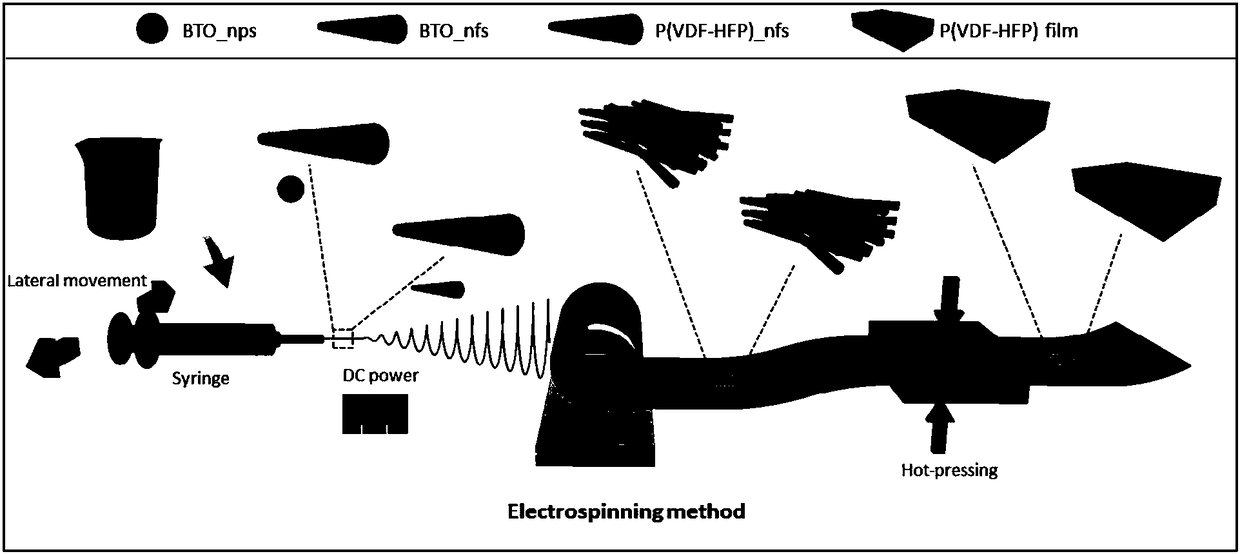

[0047] according to figure 1 The schematic flow diagram shown in the preparation of polymer nanocomposites, the specific steps are as follows:

[0048] (1) Measure 1g of polymer P(VDF-HFP) (molecular weight is 470,000), add it to a mixed solvent of 3mL of DMF and 2ml of acetone, stir until a stable sol is obtained, and obtain a precursor sol; BaTiO 3 Nanoparticles were added to the above P(VDF-HFP) sol to prepare BaTiO 3 Nanoparticles / P (VDF-HFP) sol, stir evenly to steady state, obtain precursor sol (in the gained precursor sol, the mass concentration of polymer P (VDF-HFP) is 20%; BaTiO 3 The amount of nanoparticles added is controlled in the final composite material BaTiO 3 The volume fraction of nanoparticles is 1%).

[0049] (2) The sol was transferred to a syringe for electrospinning, the injection speed was 1.0mL / h, the lateral movement distance was 80mm, the high voltage electric field was 1.3kV / cm, ...

Embodiment 2

[0052] Embodiment 2, preparation polymer nanocomposite material

[0053] according to figure 1 The schematic flow diagram shown in the preparation of polymer nanocomposites, the specific steps are as follows:

[0054] (1) Measure 1g of polymer P(VDF-HFP) (molecular weight is 470,000), add it to a mixed solvent of 3mL of DMF and 2ml of acetone, stir until a stable sol is obtained, and obtain a precursor sol; BaTiO 3 Nanoparticles were added to the above P(VDF-HFP) sol to prepare BaTiO 3 Nanoparticles / P (VDF-HFP) sol, stir evenly to steady state, obtain precursor sol (in the gained precursor sol, the mass concentration of polymer P (VDF-HFP) is 20%; BaTiO 3 The amount of nanoparticles added is controlled in the final composite material BaTiO 3 The volume fraction of nanoparticles is 5%).

[0055] (2) The sol was transferred to a syringe for electrospinning, the injection speed was 1.0mL / h, the lateral movement distance was 80mm, the high voltage electric field was 1.3kV / cm, ...

Embodiment 3

[0058] Embodiment 3, preparation polymer nanocomposite material

[0059] according to figure 1 The schematic flow diagram shown in the preparation of polymer nanocomposites, the specific steps are as follows:

[0060] (1) Measure 1g of polymer P(VDF-HFP) (molecular weight is 470,000), add it to a mixed solvent of 3mL of DMF and 2ml of acetone, stir until a stable sol is obtained, and obtain a precursor sol; BaTiO 3 Nanoparticles were added to the above P(VDF-HFP) sol to prepare BaTiO 3 Nanoparticle / P (VDF-HFP) sol, stir evenly and to steady state, obtain precursor sol (in the gained precursor sol, the mass concentration of polymer P (VDF-HFP) is 20%; BaTiO 3 The amount of nanoparticles added is controlled in the final composite material BaTiO 3 The volume fraction of nanoparticles is 10%).

[0061] (2) The sol was transferred to a syringe for electrospinning, the injection speed was 1.0mL / h, the lateral movement distance was 80mm, the high-voltage electric field was 1.3kV / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com