Evaporation source for deposition process and insulation fixing plate, and heating wire winding plate and method for fixing heating wire

A technology of insulating fixed plate and evaporation source, which is used in the manufacture of circuits, electrical components, semiconductor/solid-state devices, etc., can solve problems such as weakening of mechanical strength, cracking of heating wires, uneven temperature distribution of crucibles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings.

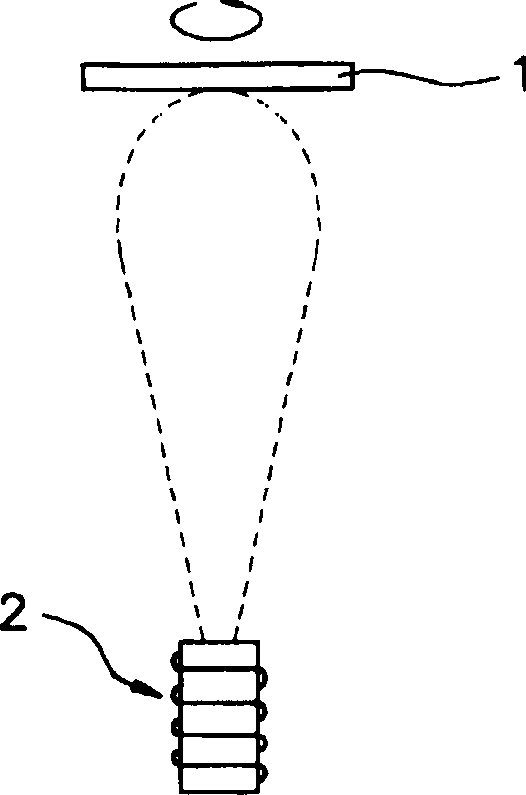

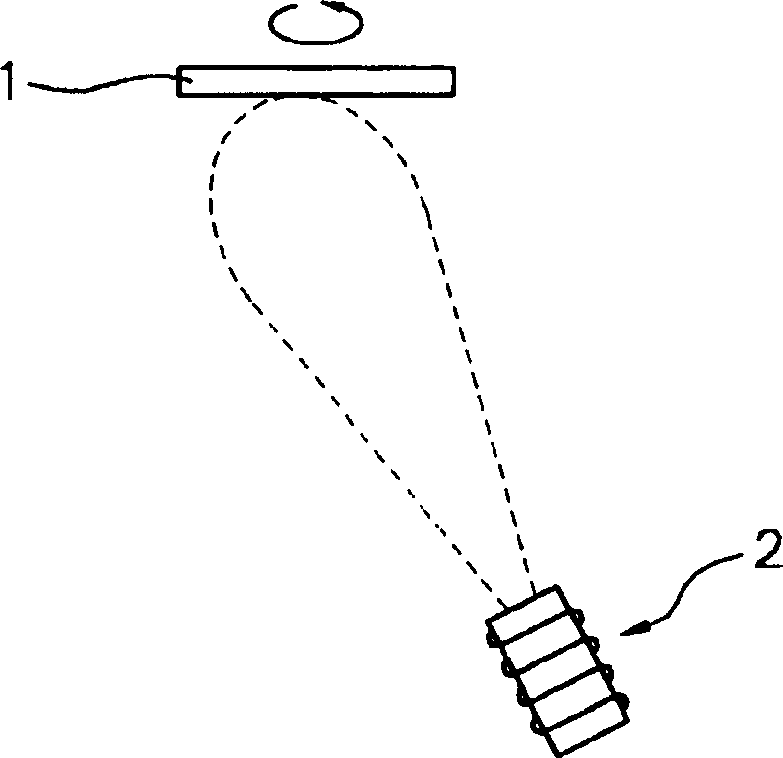

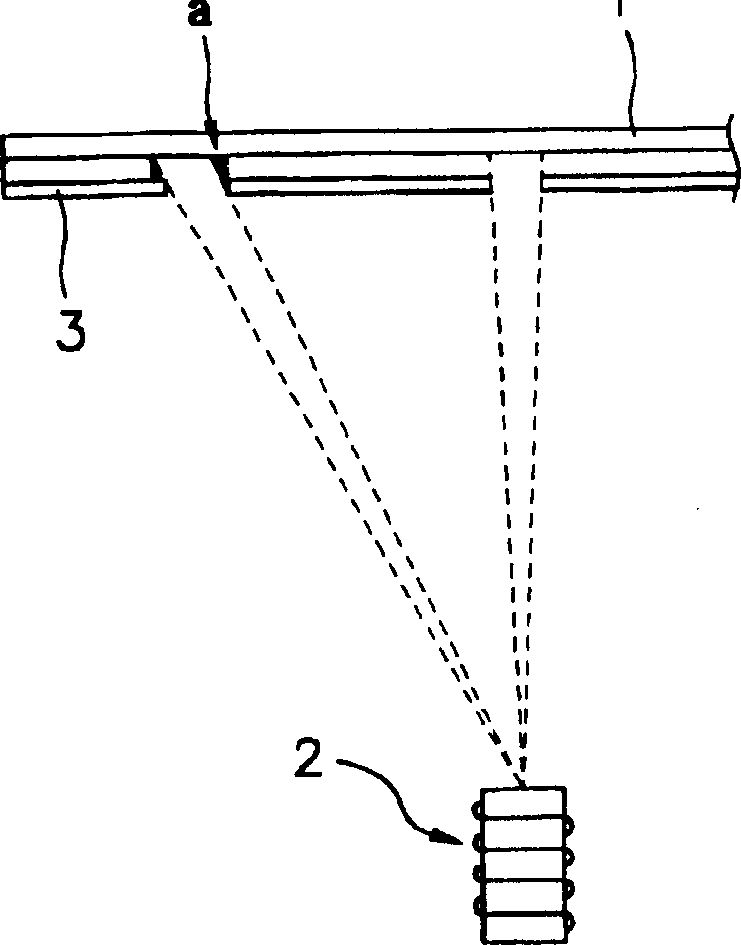

[0062] Figure 5 is a perspective view of a linear evaporation source for manufacturing a thin organic semiconductor device according to a first embodiment of the present invention, and Figure 6 yes Figure 5 The side cross-sectional view of the linear evaporation source shown in .

[0063] The crucible 10 has an opening 11 formed at one side thereof. The other side of the crucible 10 is closed to form a storage space. The deposition substance (A) is accommodated in the accommodation space. Preferably, the crucible 10 is processed into a long column shape, and the opening 11 is formed along the length direction of the crucible 10 .

[0064] Here, a thin film can be deposited by moving the crucible 10 over the opening 11 in a direction perpendicular to the length direction or vice versa.

[0065] According to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com