Display substrate, preparation method of display substrate and display panel

A display substrate and electrode technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of weak light output in the edge area, decline in device luminous brightness and efficiency, and small effective light-emitting area, achieving reduction The effect of climbing volume, increasing the area of effective light-emitting area, and alleviating the edge pinning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the embodiments of the present application will be described in detail below in conjunction with the implementation manners of the present application. It should be noted that the described implementations are only some of the implementations of the present application, not all of the implementations.

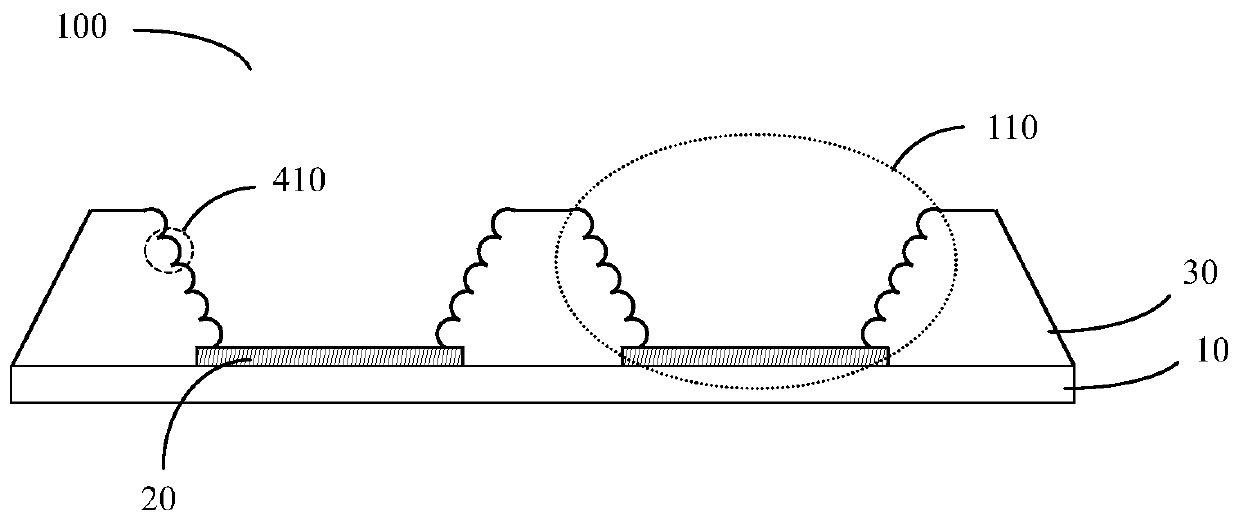

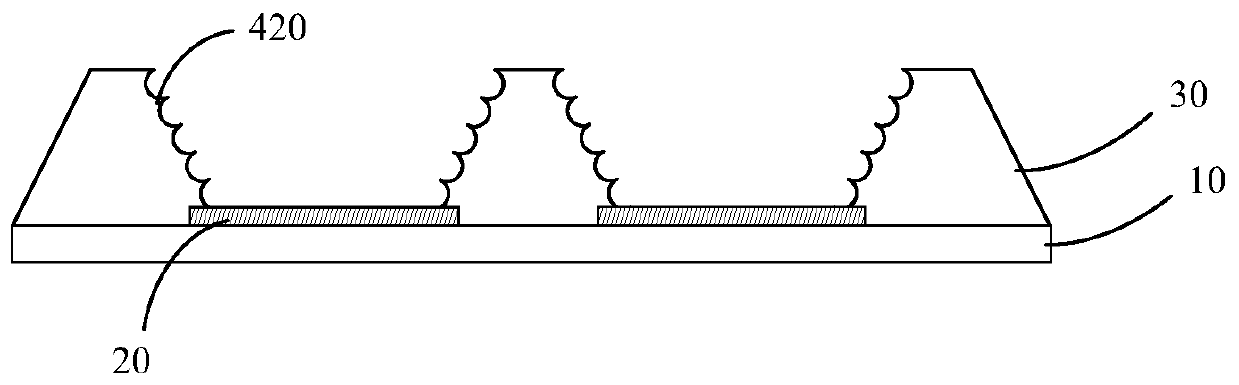

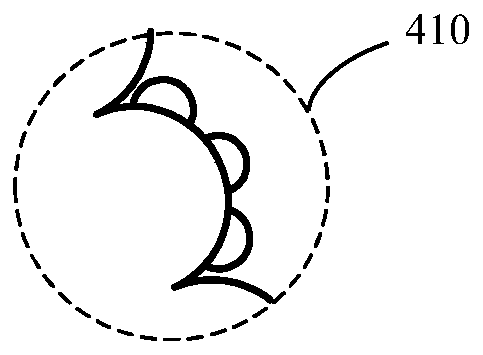

[0022] The embodiments of the present application are aimed at the preparation of quantum dot display devices by inkjet printing in the prior art. After the ink containing functional materials is printed to the designated pixel area, edge climbing occurs during the process of drying to form a film, and the display device emits light effectively. For the problems of small area and uneven luminous brightness, a display substrate and its manufacturing method and display panel are provided to solve the above problems, effectively alleviate the edge pinning effect caused by the evaporation of ink droplet solvent, and reduce the climbing volume of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com