Anti-fingerprint coating and spraying method thereof

An anti-fingerprint and coating technology, used in coatings, antifouling/underwater coatings, polyurea/polyurethane coatings, etc. Contamination and other problems, to ensure the anti-fingerprint and anti-fouling ability, reasonable spraying method, and ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

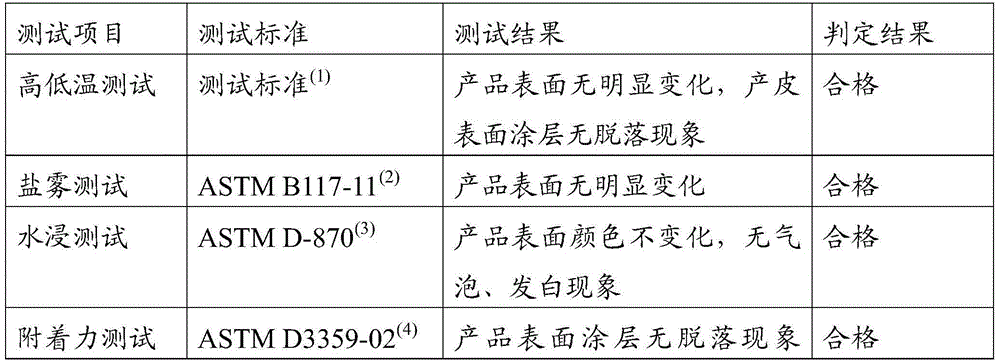

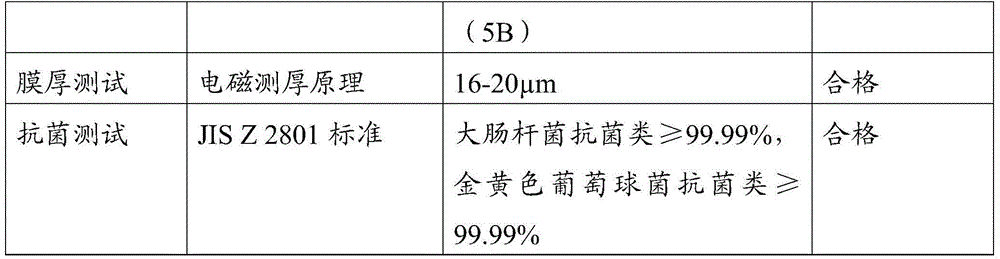

Examples

Embodiment 1

[0062] An anti-fingerprint coating and a spraying method, the specific steps are:

[0063] S1 debugs the primer paint, and fully stirs it evenly, and the debugging viscosity is 8.6S, and the components of the primer paint and the weight ratio of each component are:

[0064] 30 parts of paint;

[0065] 60 parts of diluent;

[0066] 10 parts of isocyanate;

[0067] Described diluent is the mixture of butyl acetate, ethyl acetate, butanone;

[0068] S2 debugs described anti-fingerprint coating, and fully stirs evenly, debugging viscosity is 8S, and the component of described anti-fingerprint coating and the weight ratio of each component are:

[0069] 62 parts of polyurethane UV-curable coating;

[0070] 33 parts of diluent;

[0071] 5 parts of UV curing fluorine-containing acrylic compound;

[0072] Described diluent is the mixture of butyl acetate, ethyl acetate, butanone;

[0073] S3 wipe the surface of the product with wiper water;

[0074] S4 Bake the product wiped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com