Hot plate type continuous vacuum drying system

A technology of vacuum drying and hot plate, which is applied in the direction of drying solid materials by heating, drying solid materials without heating, and drying solid materials, etc. The problem of anti-oxidation of materials, the inability to carry out continuous vacuum drying and other problems, achieve the effect of compact structure, small footprint and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

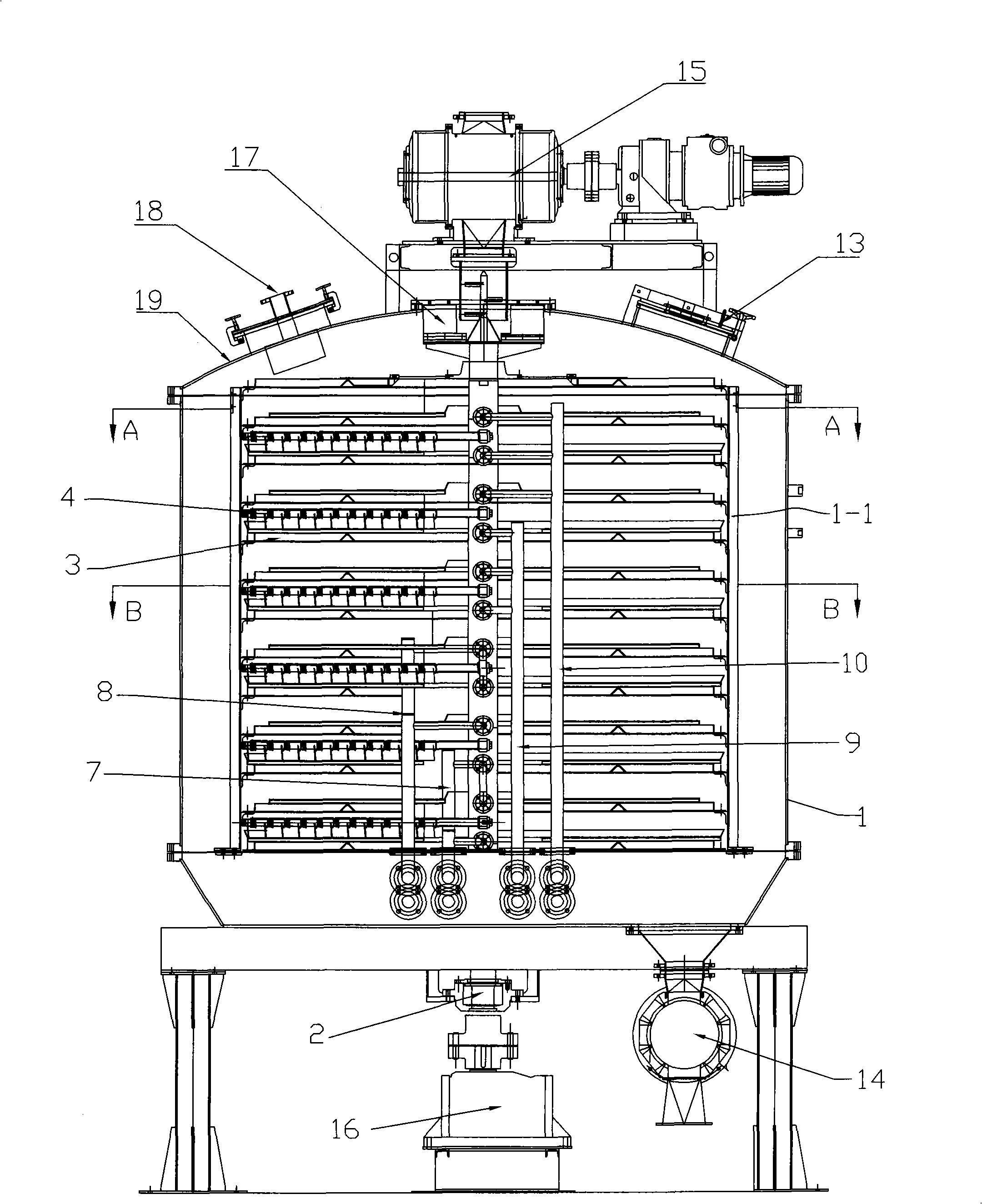

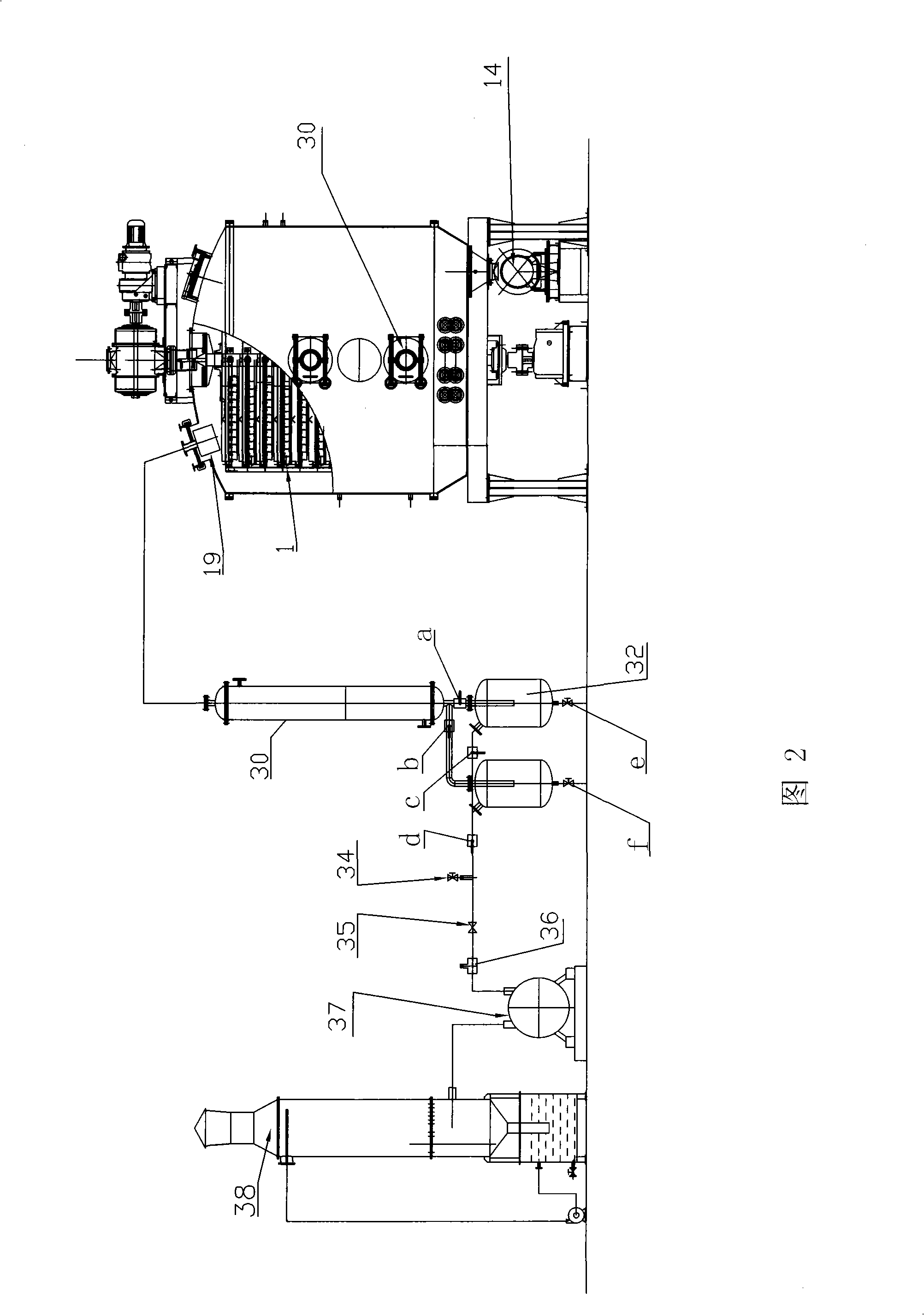

[0028] See Figure 1-6 , The hot-plate continuous vacuum drying system of this embodiment includes: a main engine, an automatic control system, a condenser 30, a pair of buffer tanks 32, a vacuum pump 37 and a dust removal and absorption device 38.

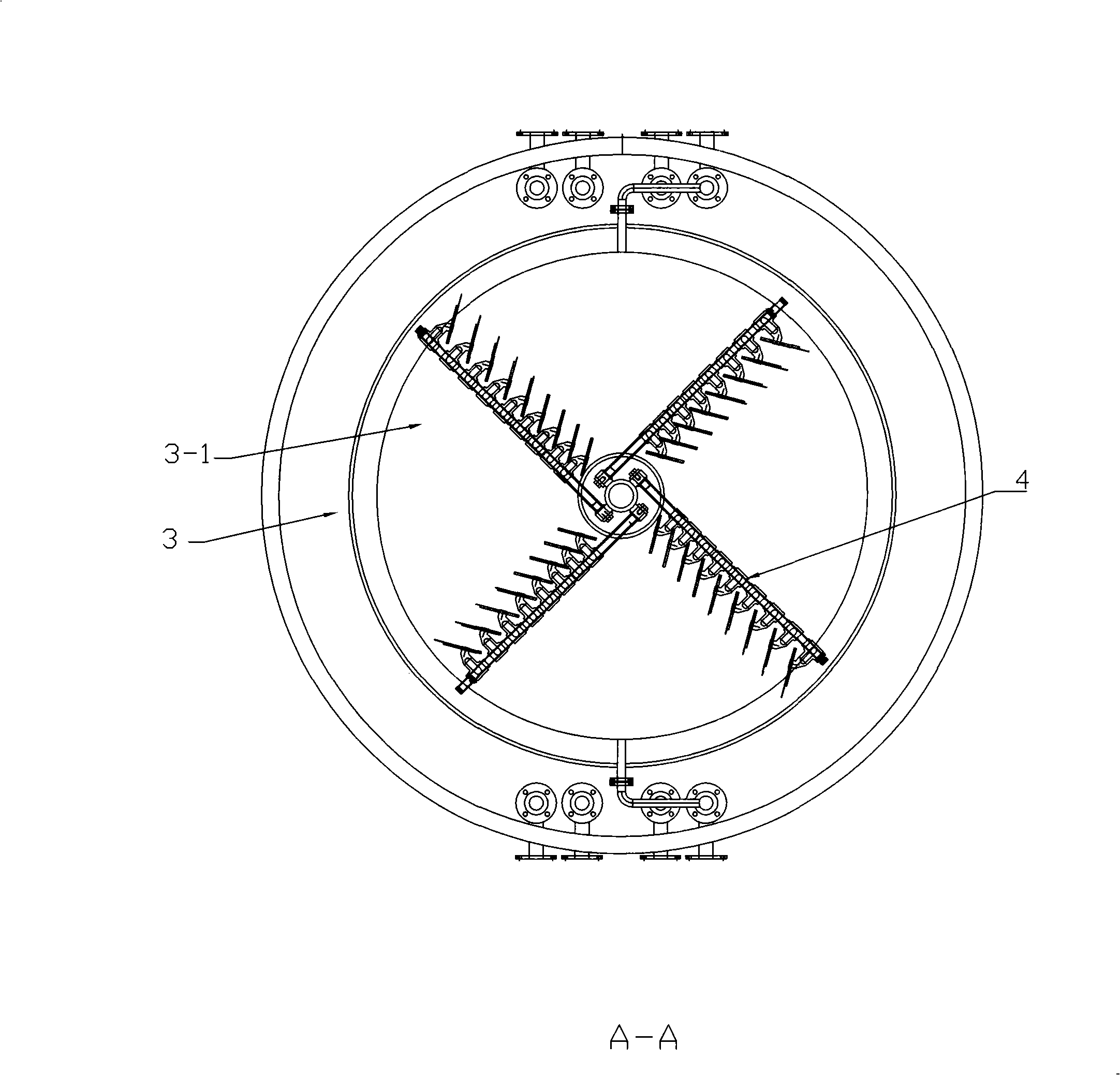

[0029] The main engine has a cylinder body 1, the cylinder body 1 is provided with a main shaft 2, the inner wall of the cylinder body 1 is provided with a bed body support 1-1, and the bed body support 1-1 is provided with 6 layers (also can be any of 4-26 layers). value) plate-type jacket heating device 3; the main shaft 2 passes through the center hole of each layer of plate-type jacket heating device 3, and is arranged between the top and bottom of the cylinder 1; the upper end surface of the plate-type jacket heating device 3 is the material surface 3-1, the main shaft 2 is provided with four support arms 4 above each material holding surface 3-1 (in other embodiments, it can be 2-6 support arms 4), and the lower end surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com