Lithium transfer type lithium supplementing method for lithium battery

A transfer type, lithium battery technology, applied in the field of electrochemical energy storage, to achieve the effect of improving the effect of lithium supplementation, improving process compatibility, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

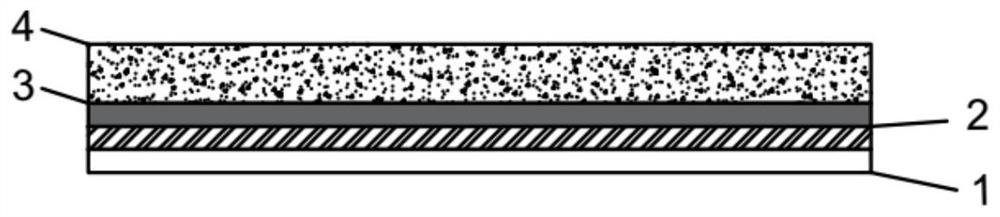

[0042] Taking PET base film-graphene-lithium metal as an example to illustrate the lithium transfer layer, the details are as follows:

[0043] see figure 1 and figure 2 , the preparation of graphene base layer 2: select single-layer graphene as base material, join 5g graphene into concentrated nitric acid: in the 30ml prefabricated reagent of water=N (5>N>1), stir overnight and carry out surface modification, The surface-modified graphene is washed with deionized water, and the washed graphene is centrifuged to remove the solution phase, and is repeatedly cleaned to PH=6; the cleaned graphene is placed in a vacuum oven for vacuum drying; The dried graphene is ground until it reaches the process requirements; the processed graphene is dispersed and homogenized using N-methylpyrrolidone (NMP), and the prepared slurry is coated on the surface of the PET base film 1 by a scraping method. The coating thickness depends on the specific process, generally in the range of 0.1-100 μ...

Embodiment 2

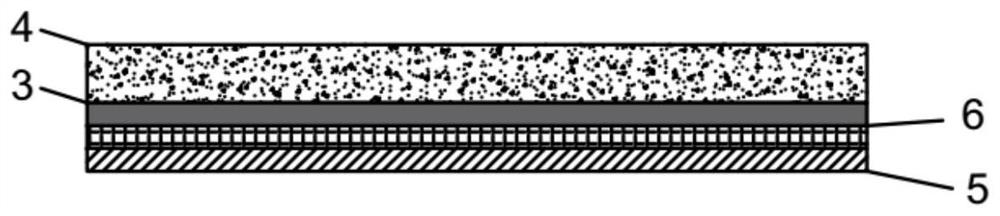

[0047] Taking copper foil-LLZTO-lithium metal as an example to illustrate the lithium transfer layer, the details are as follows:

[0048] Preparation of copper foil-LLZTO-lithium metal transfer layer: Copper foil is selected as the base film material, and 5 film rolls of the copper foil base film are placed in the vacuum chamber of the roll-to-roll magnetron sputtering coating equipment; the sputtering chamber Vacuum up to 10 -6 mbar; adjust the Ar gas flow and sputtering parameters of LLZTO and lithium target positions respectively; turn on the heater in the process area to heat the copper foil entering the process area; adjust the take-up speed according to the designed deposition thickness; click the process start button to perform LLZTO in sequence The base layer 6 and the lithium metal layer 3 are deposited; after the process stops, the gas is inflated, and the copper foil-LLZTO-lithium metal transfer layer film roll is taken out of the vacuum chamber.

[0049] The lith...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com