Super-thick copper PCB with inner and outer layers of 6OZ, and manufacturing method thereof

A PCB board, inner and outer layer technology, applied in the inner and outer layer 6OZ ultra-thick copper PCB board and its production field, can solve the problems of board thickness exceeding 2.5mm, poor thickness uniformity, cracking board, etc., and achieve the effect of ensuring thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the embodiments in the accompanying drawings, but this does not constitute any limitation to the present invention.

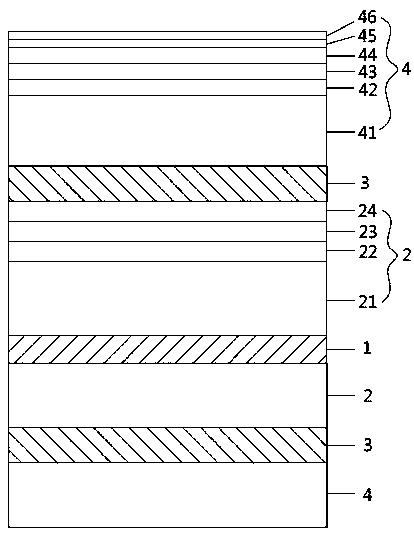

[0036] Such as figure 1 As shown, a kind of inner and outer layer 6OZ ultra-thick copper PCB board provided by the present invention is composed of a core board 1, an inner layer copper 2 electroplated on the upper and lower surfaces of the core board 1, a PP sheet 3 pressed on the inner layer copper 2 and The outer layer copper 4 is electroplated on the PP sheet 3; the total thickness of the finished PCB board is 1.4-1.6mm, wherein the thickness of the core board 1 is 0.1mm, and the minimum copper thickness of the inner layer copper 2 and the outer layer copper 4 is 6OZ (equivalent to 210μm), the thickness of the substrate excluding the outer layer copper 4 is 1.05-1.10mm.

[0037] The inner layer of copper 2 is composed of a layer of original base copper layer 21 cover...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com