Sheet thickness online measurement system based on laser ultrasound

A technology of laser ultrasound and measurement system, which is applied in electric/magnetic thickness measurement, measurement device, electromagnetic measurement device, etc., can solve the problems of unoptimistic equipment cost, large error and rough surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

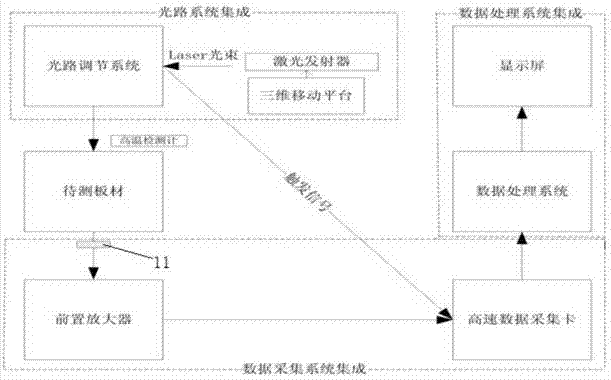

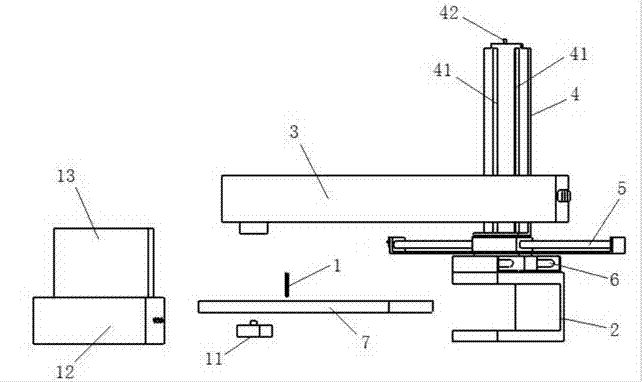

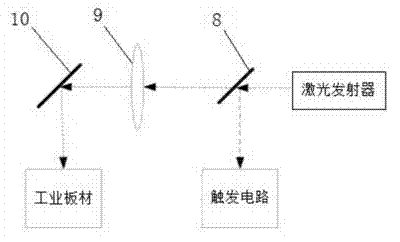

[0031] refer to Figure 1-6 : On-line measurement system for plate thickness based on laser ultrasound, including optical path system integration, pyrometer 1, data acquisition system integration, and data processing system integration;

[0032]The optical path system integration includes a U-shaped ground frame 2, a three-dimensional mobile platform, and a control cabinet 3 integrated with a laser transmitter and an optical path adjustment system. The three-dimensional mobile platform includes a Z-direction mobile station 4, an X-direction mobile station 5, a Y To the mobile station 6, the control cabinet 3 is fixed on the first mobile platform of the Z-direction mobile station 4 by bolts, and the Z-direction mobile station 4 is fixed on the second mobile platform 51 of the X-direction mobile station 5 by bolts, The X-direction mobile platform 5 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com