Residual magnetism automatic compensation device for axial magnetic vacuum arc-extinguishing chamber arc region

A vacuum interrupter and automatic compensation technology, applied in circuits, electrical switches, electrical components, etc., can solve the problems of lack of intelligent monitoring and control, poor compensation effect, etc., to reduce residual plasma diffusion and improve breaking capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

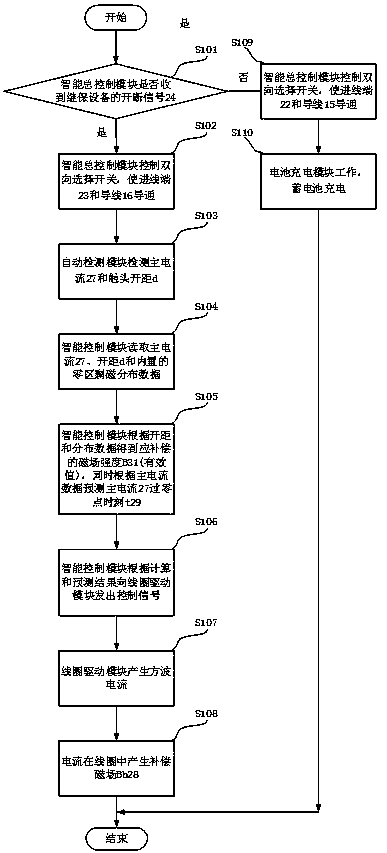

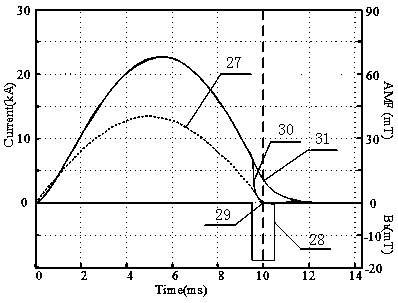

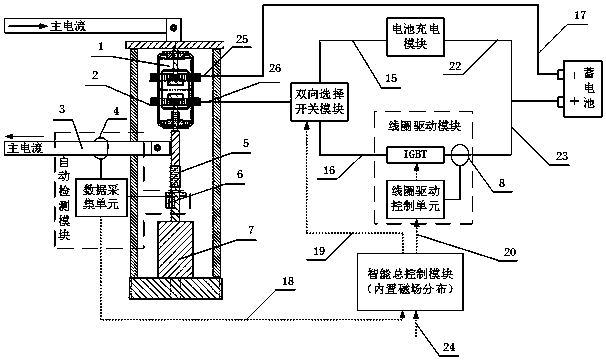

[0036] The technical solution of the present invention will be further described in detail in conjunction with the following drawings and embodiments.

[0037] like Figure 2-6 As shown, an automatic compensation device for residual magnetism in the arc area of a longitudinal magnetic vacuum interrupter includes a longitudinal magnetic vacuum interrupter 1, and the automatic compensation device for residual magnetism includes a Helmholtz coil 2, a bidirectional selection switch module, a coil drive module, Battery charging module, storage battery, intelligent general control module and automatic detection module.

[0038] The longitudinal magnetic vacuum interrupter is provided with static contacts, moving contacts, permanent magnet mechanism 7 and a driving rod. The moving contact is provided with a Helmholtz coil 2, the outgoing terminal 26 of the Helmholtz coil 2 is connected to the input terminal of the bidirectional selector switch module, and the incoming terminal 25 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com