Electromagnetic field coupled bipolar pulse magnetron sputtering system and method for increasing flow and energy

A magnetron sputtering system and bipolar pulse technology, applied in sputtering plating, ion implantation plating, metal material coating process, etc., can solve the problem of low deposition rate of high-power pulse magnetron sputtering, and achieve The effect of increasing the ionization ratio, increasing the deposition rate, and increasing the sputtering yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

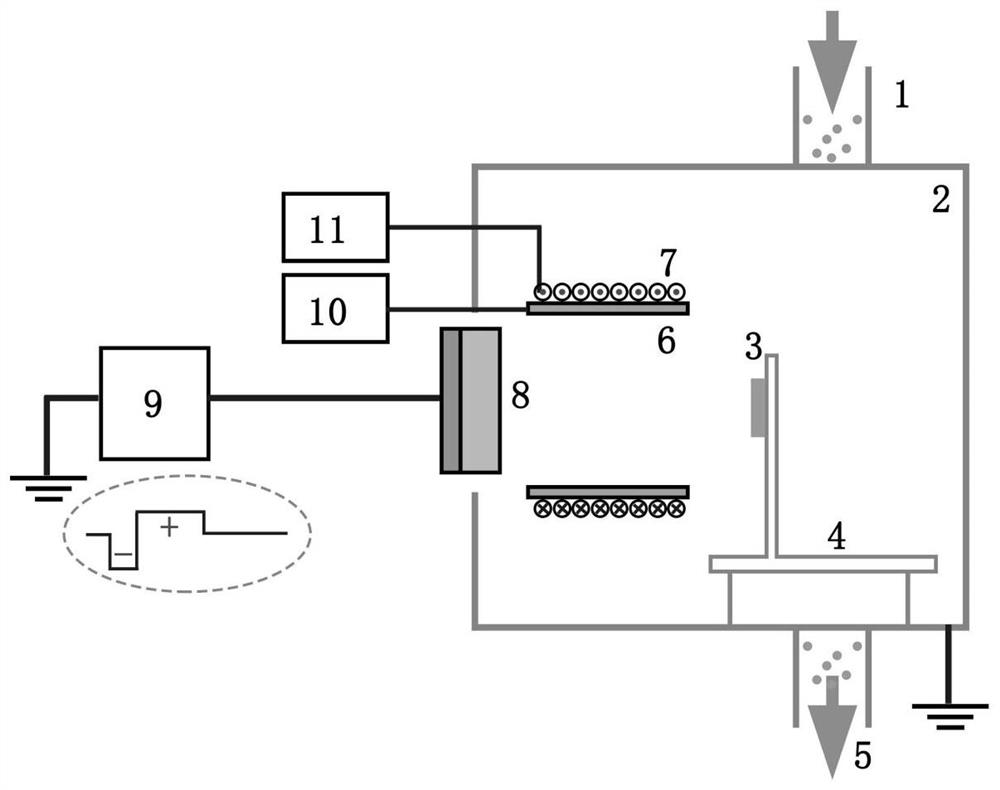

[0038] Step 1: Select an auxiliary anode of appropriate size, shape, and material, and an external magnetic field component of appropriate size and performance, and install it in front of the cathode target.

[0039] Step 2: Complete the pre-evacuation of the discharge system.

[0040]Step 3: Connect the positive and negative pulse output terminals of the bipolar pulse magnetron sputtering power supply to the cathode target.

[0041] Step 4: Select a DC power supply, or a controllable pulse power supply, or a controllable radio frequency power supply to connect to the auxiliary anode to provide voltage for the auxiliary anode.

[0042] Step 5: Introduce the working gas, adjust the voltage waveform, spatial position, and even the shape of the auxiliary anode, and adjust the position and magnetic field strength of the external magnetic field components to maximize the flow rate of deposited ions.

[0043] In step 1 of the present invention, the auxiliary anode can use conductor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com