High-voltage high-current single-pulse discharge switch and high-energy excimer laser

An excimer laser and single-pulse discharge technology, which is applied in the field of lasers, can solve the problem of excimer lasers not being able to stabilize discharge excitation, and achieve high operating voltage and high conduction power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

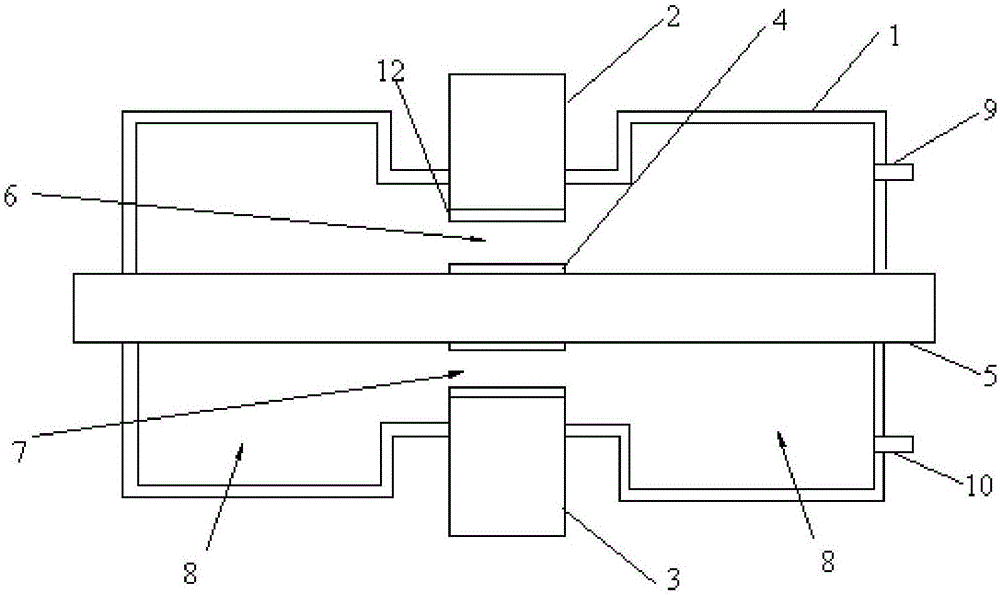

[0033] Such as figure 1 As shown, a high-voltage, high-current single-pulse discharge switch, the high-voltage, high-current single-pulse discharge switch is a closed structure, filled with high-pressure gas, and the air pressure is kept constant by the air pressure control unit, so that the high-voltage, high-current single-pulse discharge switch It can work under a certain voltage; the high-voltage and high-current single-pulse discharge switch includes a housing 1, a first electrode 2, a second electrode 3, a rotating electrode 4 and a rotating shaft 5; The inner wall of the casing 1 is covered with ceramic sheets, which improve the insulation performance and facilitate the cleaning of sputters. The rotating shaft 5 is made of stainless steel and penetrates through the housing 1; the rotation of the rotating shaft 5 adopts the magnetic coupling method to obtain the motor power outside the switch. The rotating electrode 4 is nested on the rotating shaft 5; the first electro...

Embodiment 2

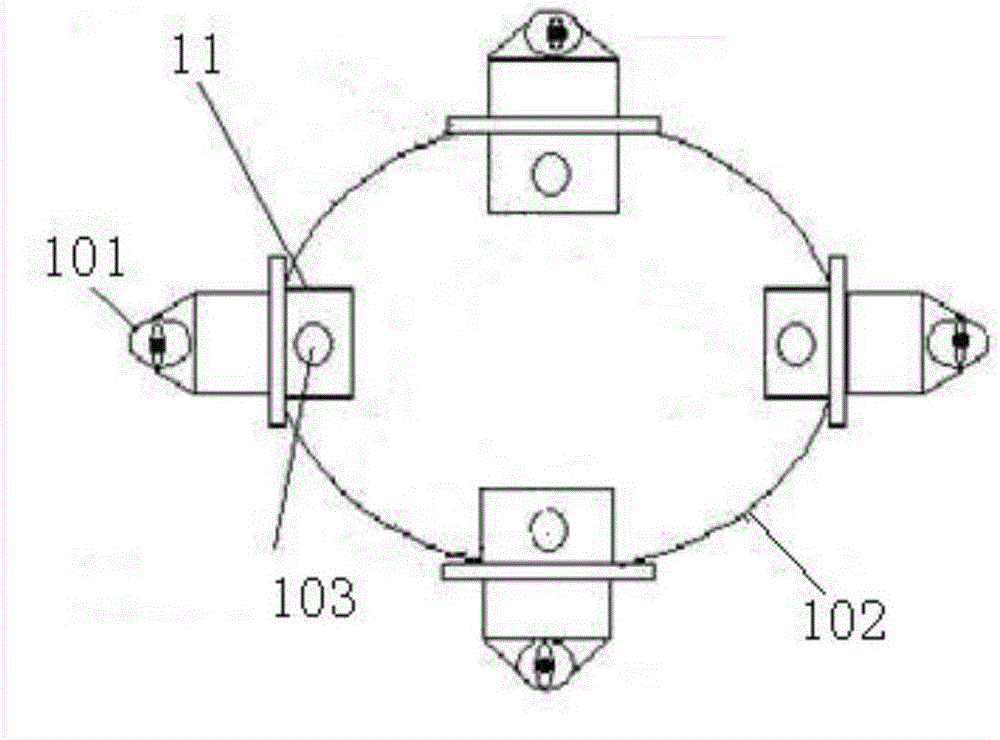

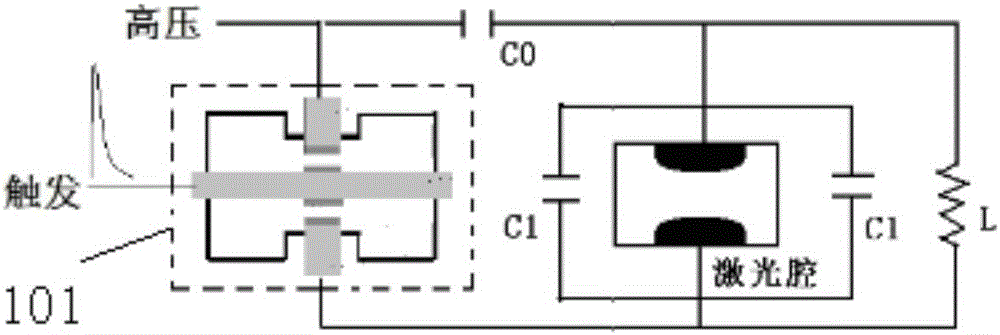

[0037] Such as Figure 1~4 As shown, a single-pulse low-frequency discharge excites a high-energy excimer laser, including a switch 101, a discharge cavity 11, and a gas storage cavity 102. The switch 101 is the same as the high-voltage, high-current single-pulse discharge switch of Embodiment 1, and the The number of discharge chambers 11 is four, and the four discharge chambers 11 are evenly arranged on the circumference of the gas storage chamber 102, and each discharge chamber 11 is controlled by a switch 101; the four discharge chambers 11 share one optical path system, the optical path system includes four optical paths 103, each optical path 103 corresponds to a discharge chamber 11, and the four optical paths 103 form an optical path system, and the optical path system is such as Figure 4 shown.

[0038] Such as figure 2 As shown, the design principle of the four discharge chambers 11: the single-pulse low-frequency discharge excites the high-energy excimer laser, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com