A mixed super capacitor

A supercapacitor, a hybrid technology, applied in the direction of capacitors, electrolytic capacitors, capacitor electrodes, etc., can solve the problems of low working voltage and hindering capacitor energy storage, etc., to reduce resistance, increase capacity and energy storage density, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

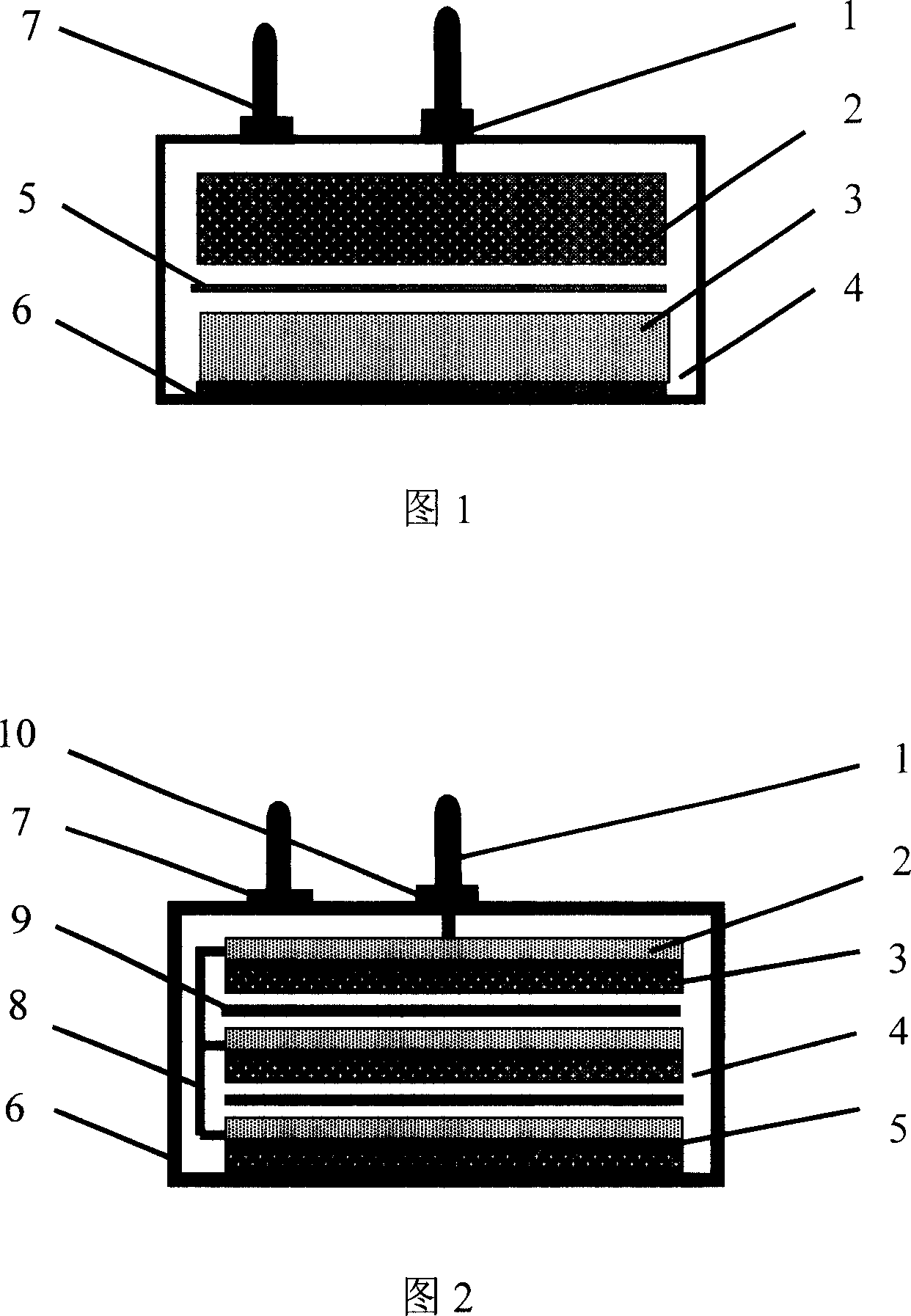

[0017] Press the prepared ruthenium dioxide film (φ35mm×0.1mm) on the substrate current collector to form a cathode 3, and separate it from the tantalum anode 2 (φ35mm×h3.2mm) with a glass fiber cloth separator 5 to form a supercapacitor unit ; Then put it into the metal tantalum shell 6, inject the electrolyte solution, and finally the two electrodes are drawn out by the anode lead 1 and the cathode lead 7 respectively. The electrolyte uses sulfuric acid with a concentration between 30% and 40%, and 2.1g of copper sulfate is added to every 100CC of sulfuric acid. In this example, the working voltage of the capacitor is designed to be 40V, the measured capacity is 6mF, the internal resistance is 0.78Ω, and the energy storage density is 1.03J / cm 3 .

[0018] This example should not be construed as a limitation of the present invention, and all inventions realized by other formal modifications, replacements or changes based on the technical idea of the present invention belon...

Embodiment 2

[0020] The hybrid supercapacitor internally uses three units connected in parallel. The manufacturing method of the units is the same as that in Embodiment 1, and the units are stacked in parallel and separated by insulating partitions 9 of glass fiber cloth. The three cathodes do not need to be physically connected, they are connected through the electrolyte, and finally lead out from the cathode lead 7, and the three anodes are connected through the internal connection 8, and finally lead out from the anode lead 1. The glass insulator 10 insulates the anode lead 1 from the casing 6, and the cathode lead 7 is connected to the casing 6; in this embodiment, the unit operating voltage is 40V, the measured capacity is 18.4mF, the internal resistance is 0.25Ω, and the energy storage density is 1.16J / cm 3 .

Embodiment 3

[0022] 30g of RuCl 3 ·xH 2 Dissolve O in distilled water to obtain a 0.1mol / L solution; add 0.3mol / L NaOH solution slowly to RuCl 3 ·xH 2 In the O solution, the pH of the solution is strictly controlled to be 7. The resulting black RuO 2 ·xH 2 O particles were filtered, rinsed several times with distilled water, and then dehydrated at 100° C. for 10 hours to obtain amorphous hydrated ruthenium dioxide. The hydrated ruthenium dioxide powder was mixed with absolute ethanol, carbon black conductive agent and polytetrafluoroethylene binder in a mass ratio of 90:4:3:3, and pressed into an electrode film with a thickness of 0.2 mm. The measured specific capacity of the electrode was 736F / g, and the internal resistance was 0.82Ω.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com