Novel titanate capable being used as lithium ion secondary battery cathode material

A negative electrode material and secondary battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve problems such as unsuitable for large-scale industrial use, small battery application range, and full battery voltage drop, and achieve cheap raw materials and good processing Performance, Effect of High Operating Voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Li 2.1 SrTi 6 o 14 preparation

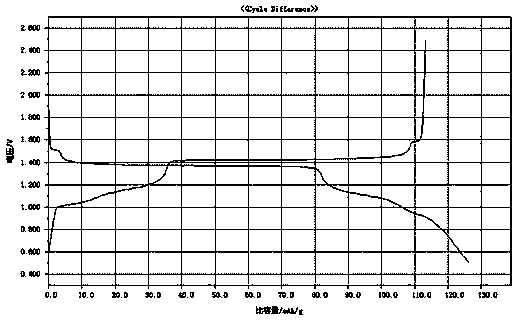

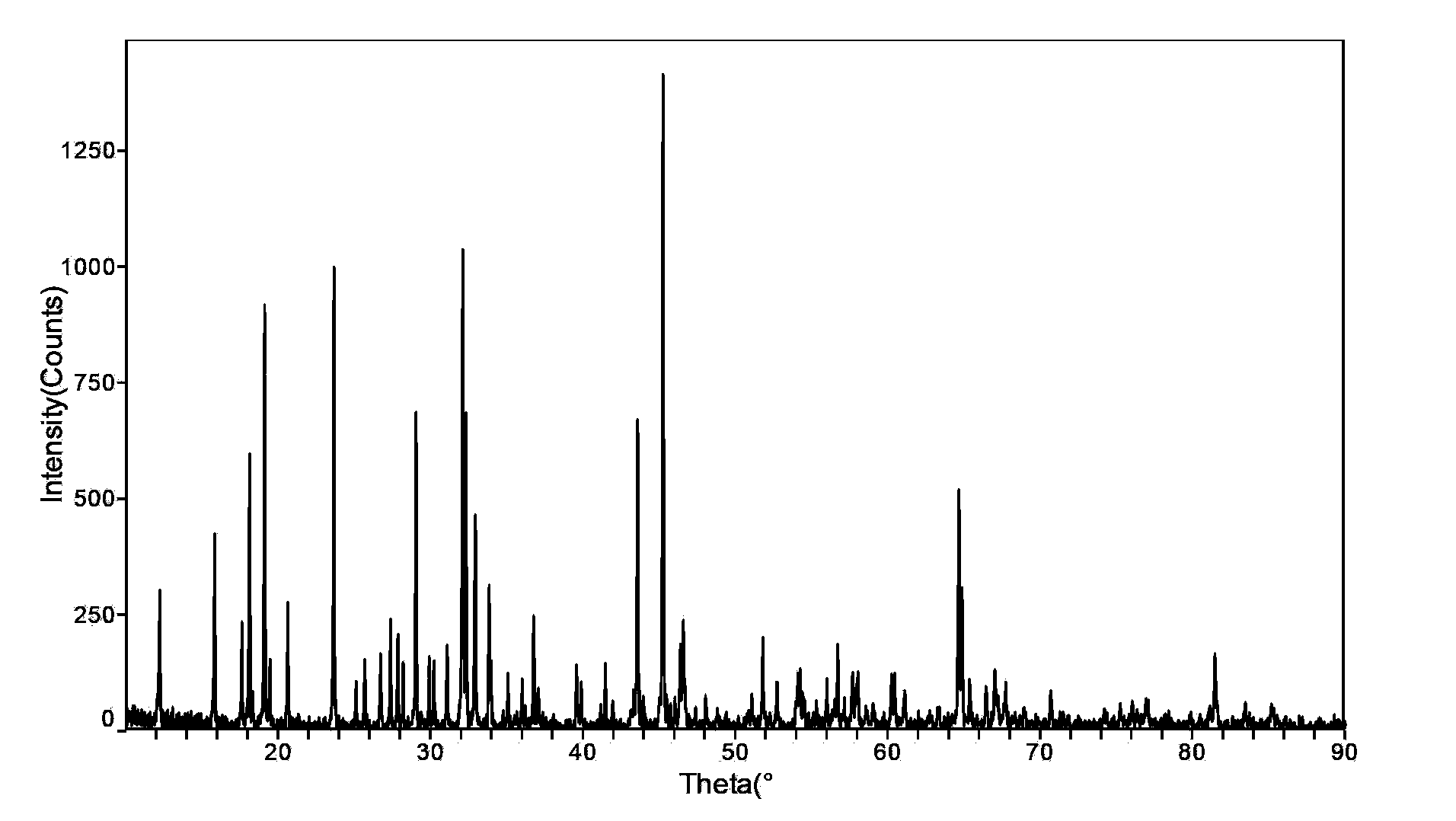

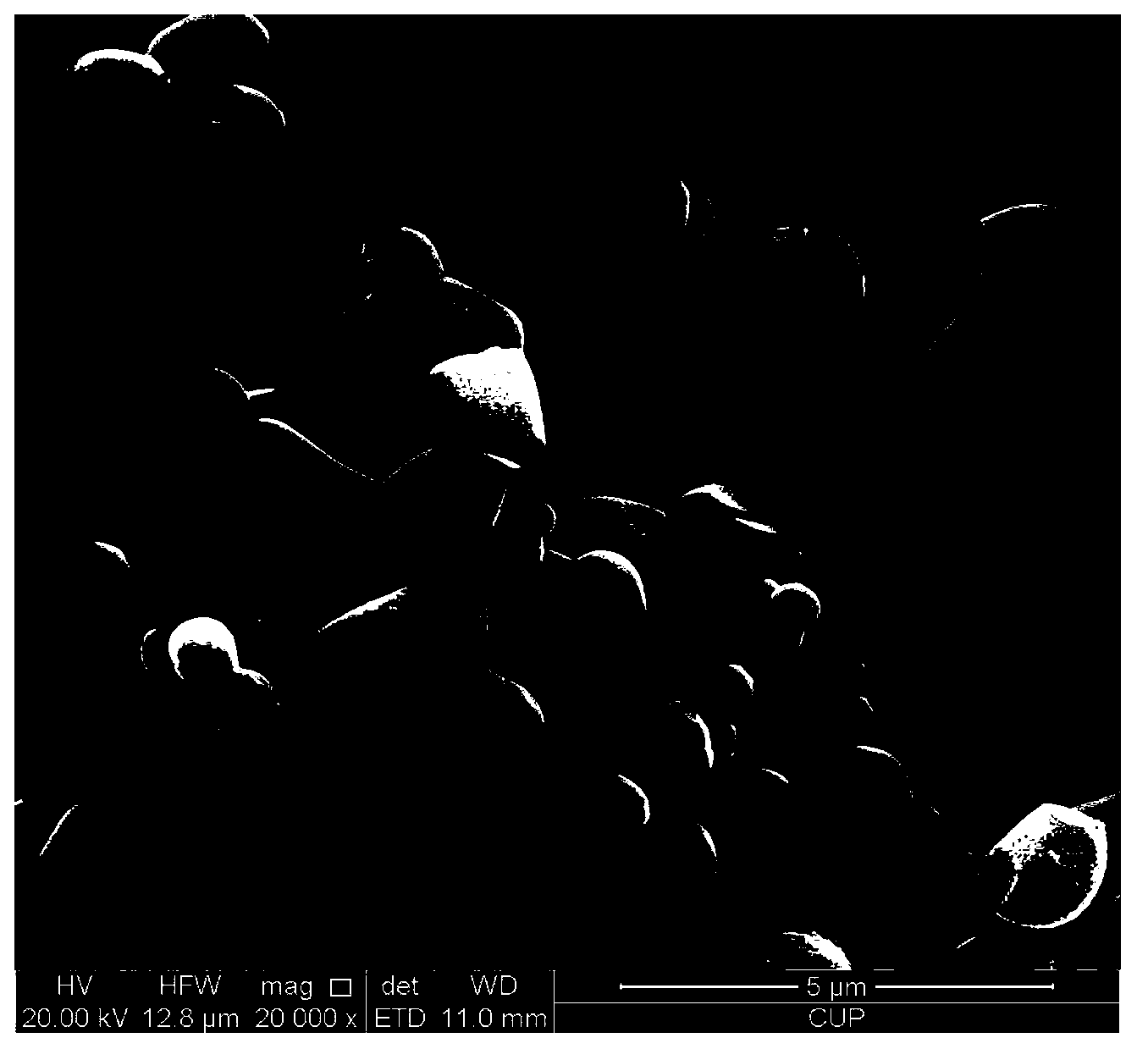

[0031] Lithium carbonate, anatase titanium dioxide and strontium carbonate are selected as raw materials, and the ingredients are mixed according to the molar ratio Li:Sr:Ti=2.1:1:6. After mixing, they are placed in an atmosphere furnace, and the temperature is raised at 5°C / min in an air atmosphere. Raise the speed to 700°C, keep it warm for 8 hours, and then cool it down to room temperature naturally. After grinding and pulverizing, put the powder in the atmosphere furnace, and heat it up to 1000°C in the air atmosphere for 24 hours, and then cool it down to room temperature naturally to get Pale yellow product. figure 1 Its X-ray diffraction pattern, Figure II Its scanning electron microscope (SEM) photo, its charge-discharge voltage-capacity curve for Li+ / Li is image 3 .

Embodiment 2

[0033] Li 2.1 SrTi 6 o 14 preparation of

[0034] Lithium carbonate, anatase titanium dioxide and strontium hydroxide are selected as raw materials, and the molar ratio is Li:Sr:Ti=2.1:1:6. After mixing, they are placed in an atmosphere furnace. Raise the heating rate to 700°C, keep it warm for 8 hours, and then cool it down to room temperature naturally. After grinding and pulverizing, put the powder in an atmosphere furnace, and heat it up to 1000°C in an air atmosphere for 24 hours, and then cool it down to room temperature naturally. A pale yellow product was obtained.

Embodiment 3

[0036] Li 2.1 Sr 0.98 Mg 0.02 Ti 6 o 14 preparation of

[0037] Lithium carbonate, anatase titanium dioxide, strontium carbonate and magnesium hydroxide are selected as raw materials, and the ingredients are mixed according to the molar ratio Li:Sr:Mg:Ti=2.1:0.98:0.02:6. The temperature was raised to 700°C at a rate of 5°C / min, kept at a temperature of 8 hours, and then cooled to room temperature naturally. After being ground and pulverized, the powder was placed in an atmosphere furnace, and heated to 1000°C in an air atmosphere for 24 hours. After cooling naturally to room temperature, a pale yellow product can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com