Plasma processing equipment and cleaning system and method thereof

A technology of plasma and processing equipment, applied in the field of plasma processing, can solve the problems of etching eccentricity, uneven field strength at the edge of the electric field, uneven plasma distribution, etc., and achieve the effect of avoiding etching eccentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

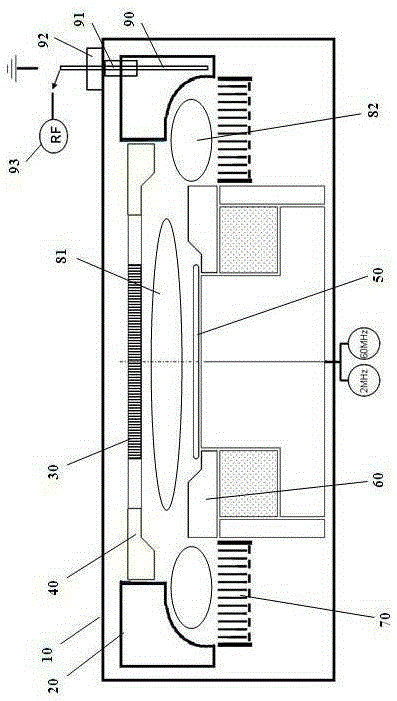

[0047] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

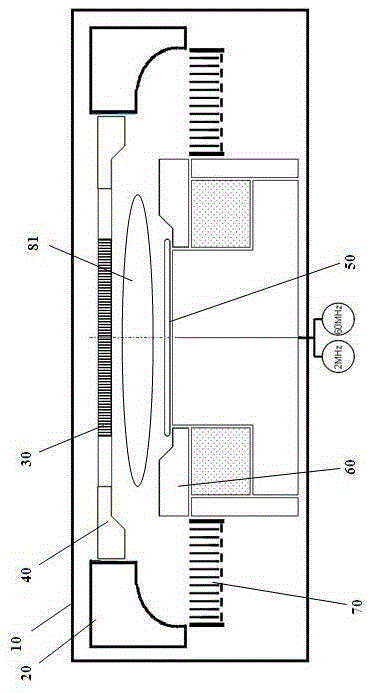

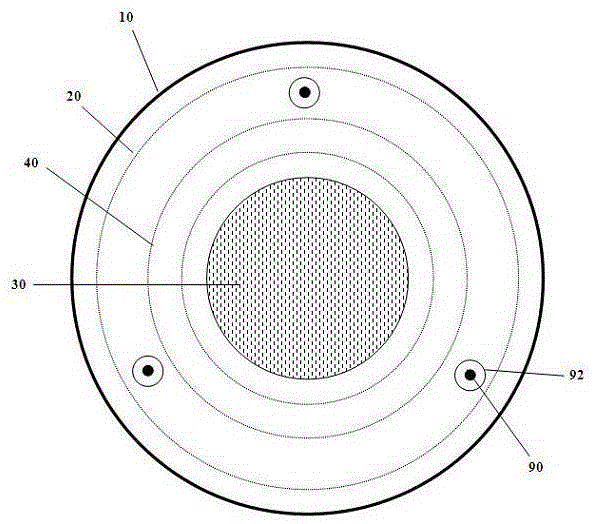

[0048] like figure 2 As shown, the plasma processing equipment provided by the present invention includes a reaction chamber 10, which has a metal chamber wall and is usually in a vacuum state during the etching process and cleaning process.

[0049]The top of the reaction chamber 10 is provided with a shower head 30 to introduce the reaction gas of the etching process into the reaction chamber 10; the first electrode provided at the shower head 30 is grounded; Ring 40. A base 50 is provided at the bottom of the reaction chamber 10 for carrying and holding the substrate placed on the base 50 . Through the radio frequency electric field formed in the reaction chamber 10, the reaction gas in the reaction chamber 10 is dissociated to form plasma, and the surface of the substrate is etched and other processes are performed.

[0050] The base 50 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com