Plasma processing apparatus

A plasma and processing device technology, which is applied in the field of plasma processing devices, can solve the problems of difficult sputtering etching of generated reactants, high difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

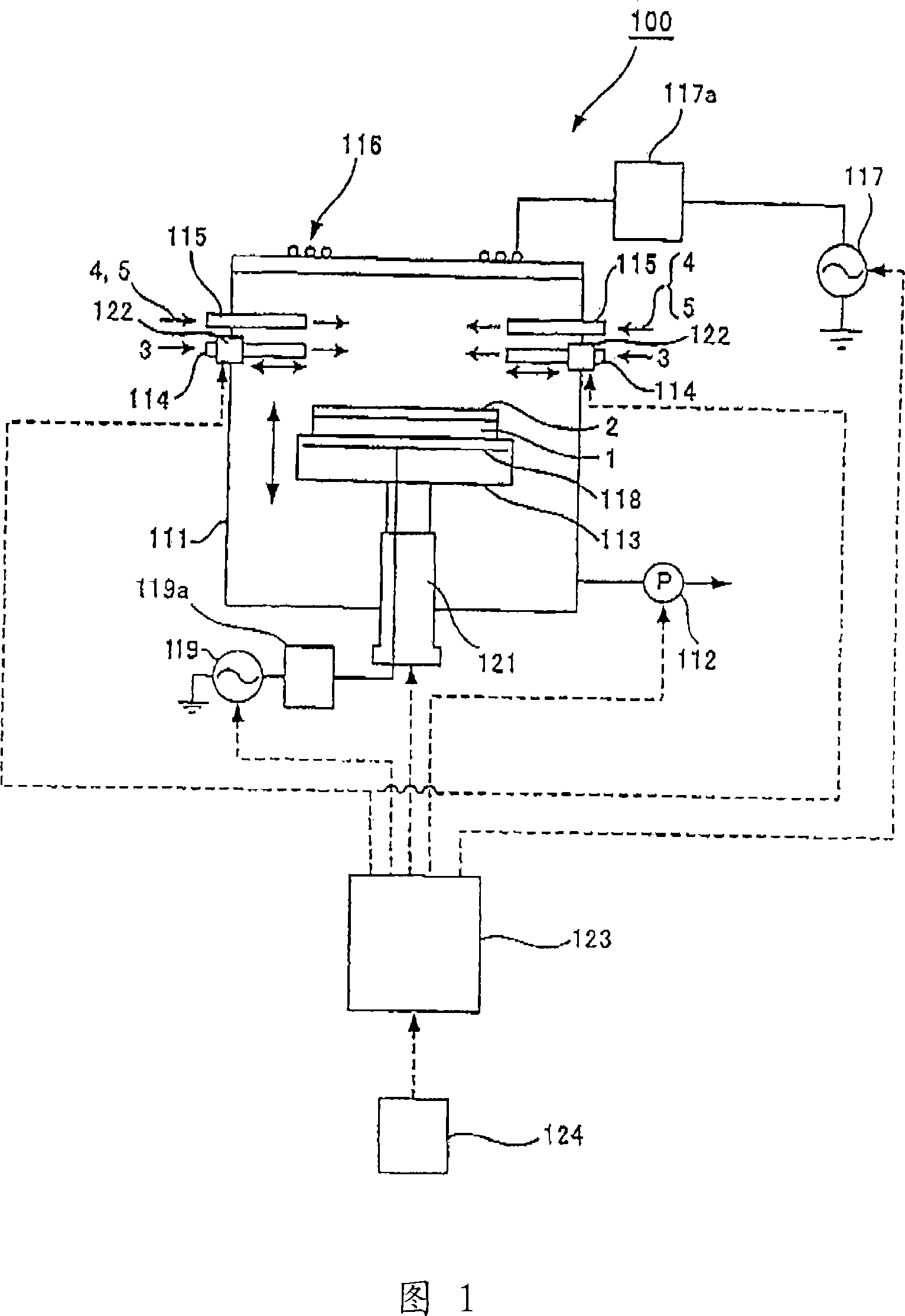

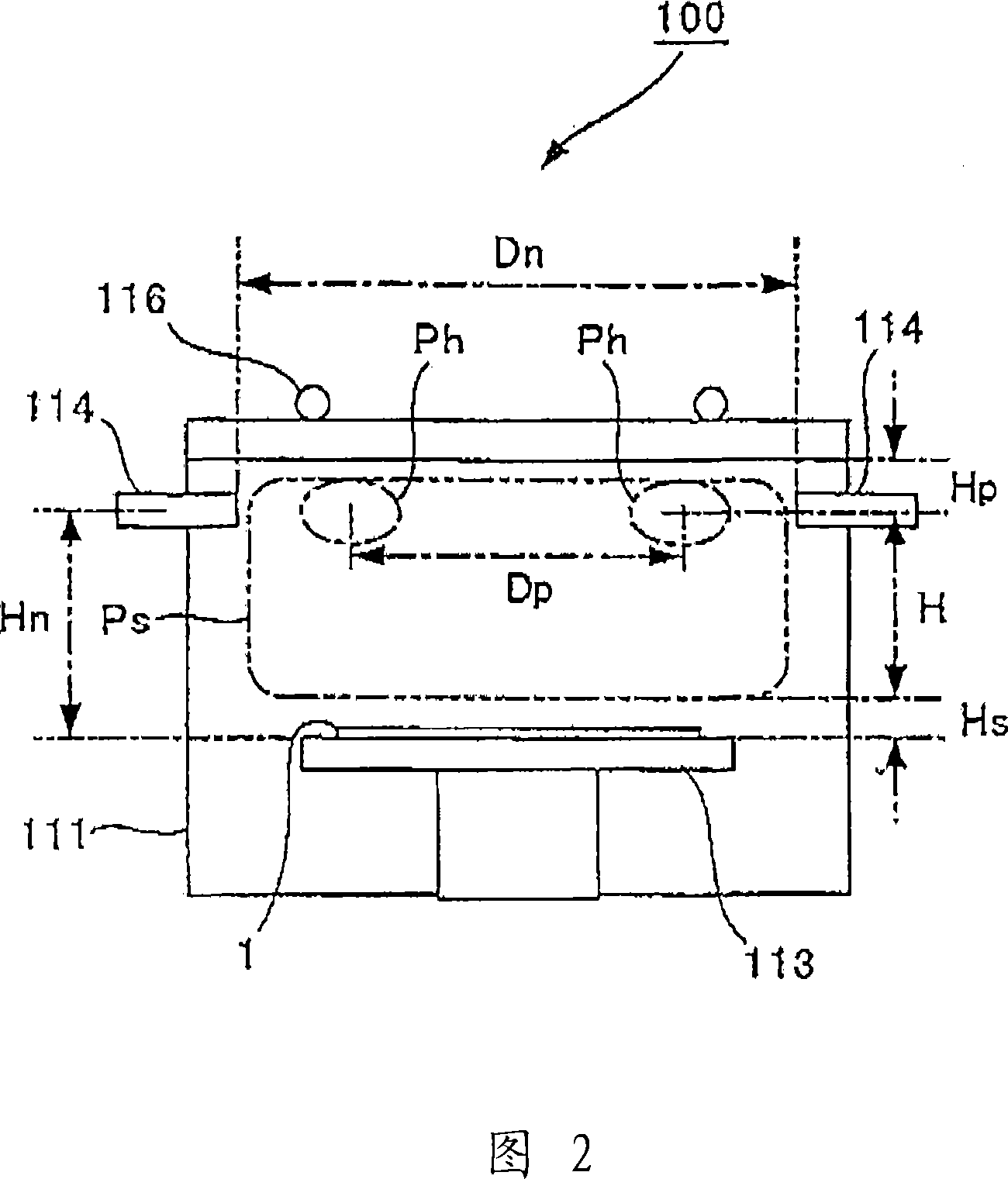

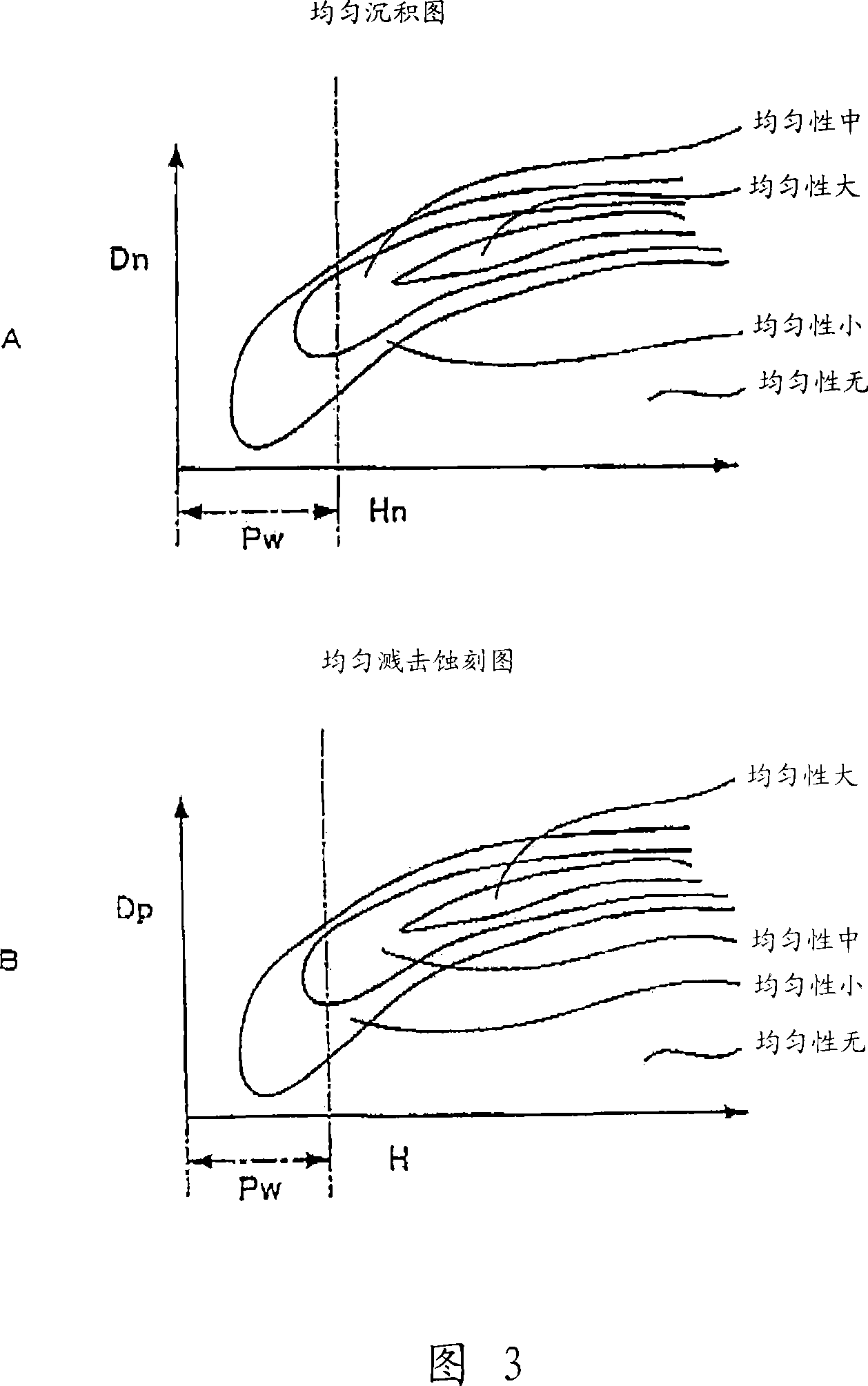

[0026]A first embodiment of the plasma processing apparatus of the present invention will be described with reference to FIGS. 1 to 4 . Fig. 1 is a schematic configuration diagram of a plasma processing apparatus; Fig. 2 is an explanatory diagram of main parts of the plasma processing apparatus of Fig. 1; A in Fig. 3 is a uniform deposition map, which is stored in the control of the plasma processing apparatus of Fig. 1 In the device, B is a uniform sputter etching map, which is stored in the control device of the plasma processing device in FIG. 1; FIG. 4 is a flowchart showing the sequence of the plasma processing method.

[0027] As shown in FIG. 1 , an elevating device 121 as an elevating mechanism is provided below the inside of a cylindrical vacuum reaction chamber 111 to which an exhaust pump 112 , which is an exhaust mechanism, is connected. In the lifting device 121 , a disk-shaped support table 113 for supporting the substrate 1 is installed so as to be coaxial with ...

no. 2 Embodiment approach

[0042] 5 to 7 are schematic representations of a plasma processing apparatus according to a second embodiment of the present invention. 5 is a schematic configuration diagram of a plasma processing apparatus, FIG. 6 is an explanatory diagram of main parts of the plasma processing apparatus of FIG. 5 , and FIG. 7 is a flow chart showing the procedure of a plasma processing method. Furthermore, regarding the parts that are the same as those of the above-mentioned first embodiment, since the symbols used here are the same as those used in the above-mentioned first embodiment, the parts that overlap with the description of the above-mentioned first embodiment will be omitted here. .

[0043] As shown in FIG. 5 , on the inner bottom surface of the vacuum reaction chamber 111 , a cylindrical support platform 213 for supporting the substrate 1 is provided, which is coaxial with the vacuum reaction chamber 111 . On the top of the vacuum reaction chamber 111, a plurality of ring-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com