Novel longitudinal magnetic contact system with embedded magnetism gathering ring and reverse contact cup

A technology of contact system and magnetic gathering ring, which is applied in the direction of high-voltage air circuit breakers, electrical components, electric switches, etc., can solve the problems of reducing the recovery speed of medium strength, successfully breaking unfavorable currents, and insufficient breaking capacity, so as to achieve weakening The residual longitudinal magnetic field in the center of the contact is beneficial to the improvement of the breaking capacity and the control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

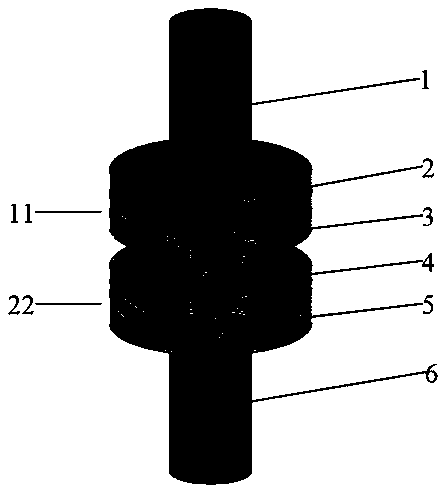

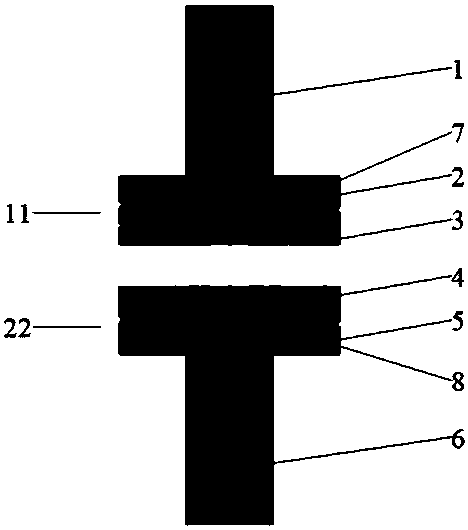

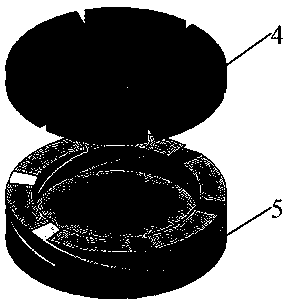

[0017] The present invention proposes a new contact system with an embedded magnetic focusing ring and a reverse contact cup. The present invention will be further described with reference to the accompanying drawings.

[0018] Such as figure 1 , 2 As shown, the overall structure of the new longitudinal magnetic contact system includes: moving and static side contact combination structures 11, 22; the static side contact combination structure includes a static conductive rod 1, an external static contact cup 2, an embedded magnetization The ring 7 and the contact piece 3; the moving-side contact assembly structure includes a moving conductive rod 6, an external moving contact cup 5, a contact piece 4, and an embedded reverse contact cup 8. Among them, the dynamic and static conductive rods 6 and 1 are coaxially connected to the tops of the outer contact cups 5 and 2 respectively, and the contact pieces 4 and 3 are coaxially connected to the bottoms of the outer contact cups 5 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com