Discharge plasma diffusion welding manufacture method for Laval nozzles

A discharge plasma and Laval tube technology, applied in the direction of manufacturing tools, non-electric welding equipment, welding equipment, etc., can solve the problems of water tank 4 blockage, low welding strength, long welding cycle, etc., and achieve small component deformation, high dimensional accuracy, No environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

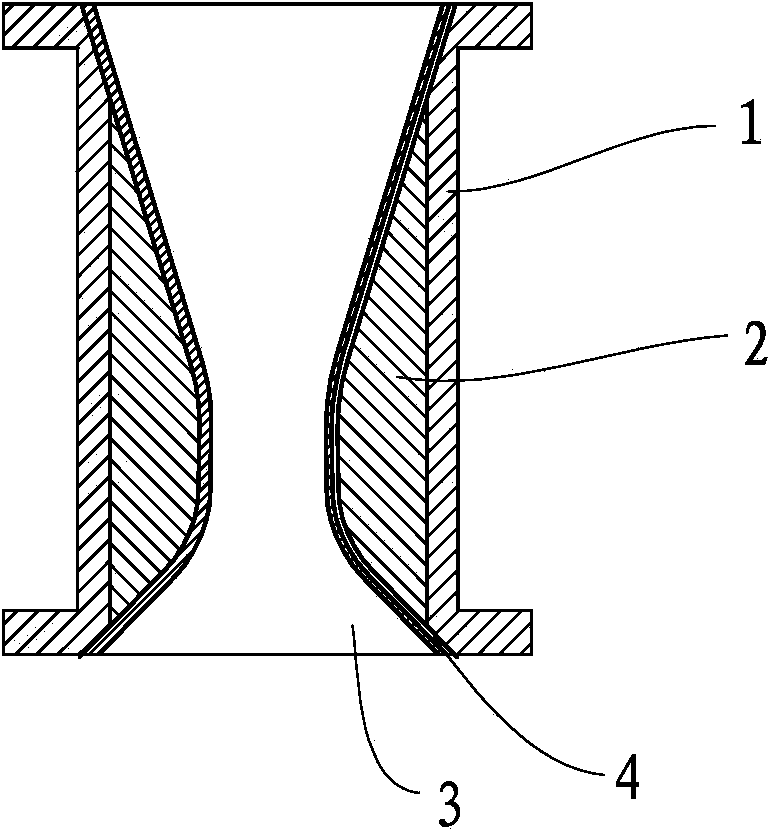

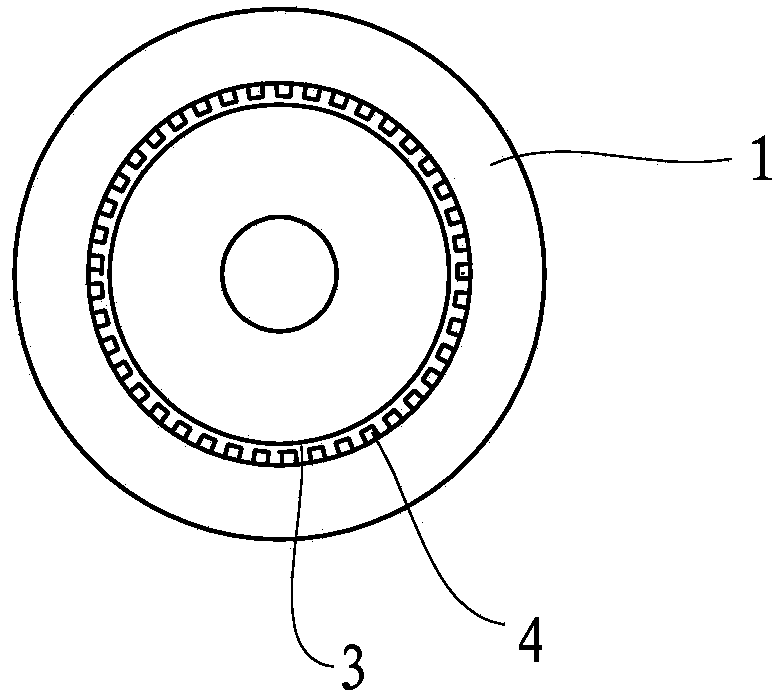

[0052] see figure 1 , figure 2 , image 3 , Figure 4 As shown, the Laval tube discharge plasma diffusion welding manufacturing method of a preferred embodiment of the present invention mainly includes the following steps:

[0053] (1) Cutting, according to the blank material and size required by the process, the outer tube 1, convex tube 2 and water cooling jacket 3 of the Laval tube are cut;

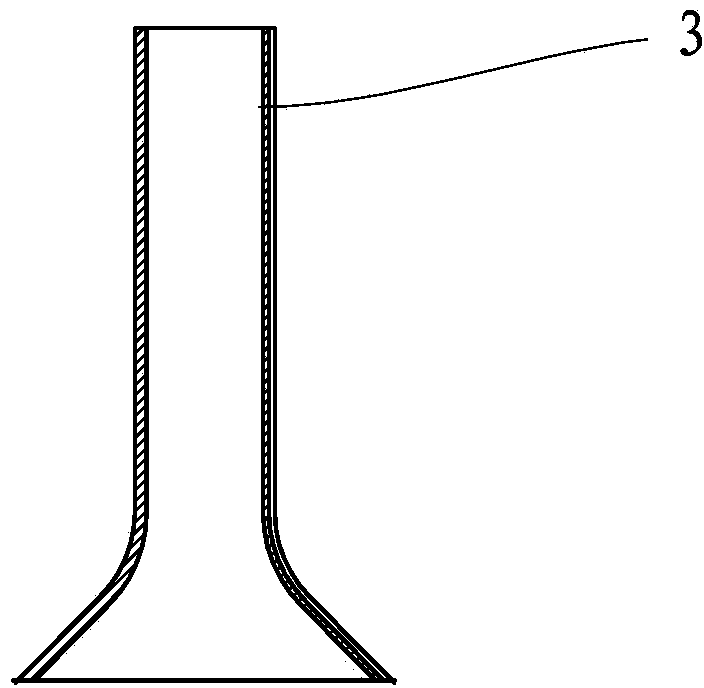

[0054] (2) Machining and forming, the outer tube 1, the convex tube 2, the water cooling jacket 3 and the water tank 4 on the outer wall of the water cooling jacket are machined and formed, and the parts that need diffusion welding are finely turned to a roughness of ≤1.6μm; the water cooling jacket 3 press image 3 Processing; the inner diameter of the outer tube 1 and the outer diameter of the convex tube 2 are hot press interference fit;

[0055] (3) Chemical degreasing and surface oxidation;

[0056] (4) drying, drying in a drying box with a blower;

[0057] (5) assembly, ...

Embodiment 2

[0063] The difference between this embodiment and Embodiment 1 is that the outer tube 1 and the convex tube 2 in the Laval tube are combined into one piece, which is integrally formed by machining, and the assembly between the outer tube 1 and the convex tube 2 is omitted and welding. Its processing includes the following steps:

[0064] (1) Cutting, according to the blank material and size required by the process, cutting the Laval tube substrate and water cooling jacket;

[0065] (2) Machining and forming, the Laval tube base and the water cooling jacket are machined, and the parts that need diffusion welding are finished to a roughness of ≤1.6μm; the water cooling jacket is press image 3 processing;

[0066] (3) Chemical degreasing and surface oxidation;

[0067] (4) drying, drying in a drying box with a blower;

[0068] (5) Assemble, insert the water-cooling jacket into the base of the outer tube Laval tube and flaring;

[0069] (6) Discharge plasma diffusion welding...

Embodiment 3

[0072] The present invention also proposes yet another method for manufacturing the above-mentioned Laval tube discharge plasma diffusion welding. The difference between this embodiment and Embodiment 1 or 2 is that the water-cooling tank 4 arranged on the outer surface of the water-cooling jacket 3 is changed to be located on Laval. On the wall of the inner hole of the tube base, the advantage is that the water cooling jacket 3 deforms evenly when the mouth is flared, and the disadvantage is that it is more difficult to process the water cooling groove in the inner hole than on the outer surface. This embodiment includes the following steps:

[0073] (1) Cutting, according to the blank material and size required by the process, cutting the Laval tube substrate and water cooling jacket;

[0074] (2) Machining and forming, the Laval tube base and water cooling jacket are machined, and the parts that need diffusion welding are finished to a roughness ≤ 1.6μm; the outer wall of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com