Preparation method of boron nitride coating on fiber surface

A fiber surface, boron nitride technology, applied in the field of preparation of boron nitride coating on the fiber surface, can solve the problems of inflammability and explosion, toxic raw material gas, difficult to handle, etc., and achieve smooth, uniform, dense and uniform thickness of the coating surface Consistent, saturated vapor pressure results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

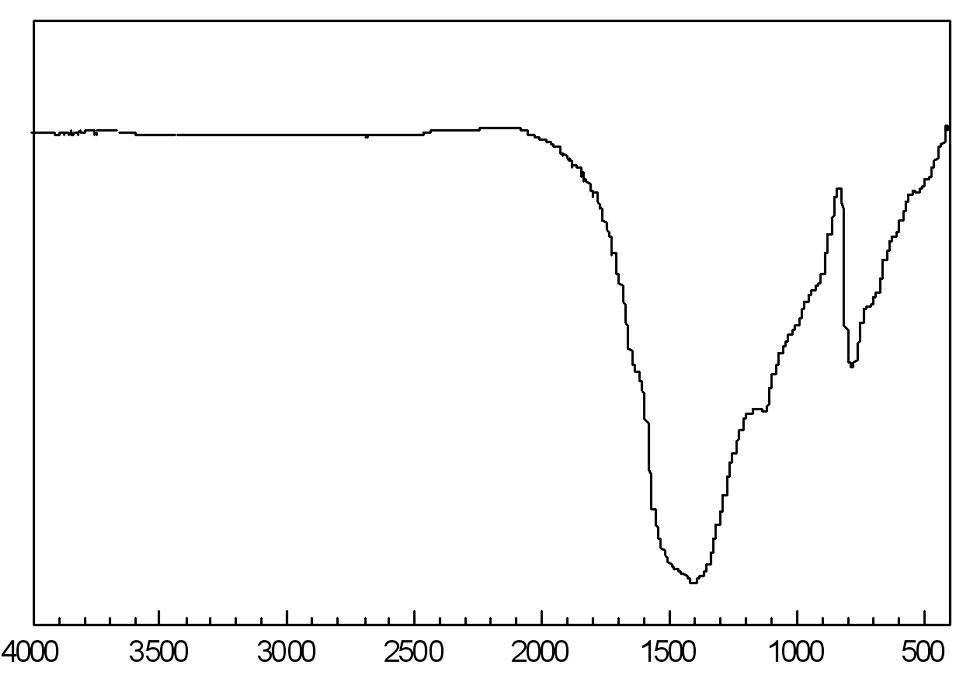

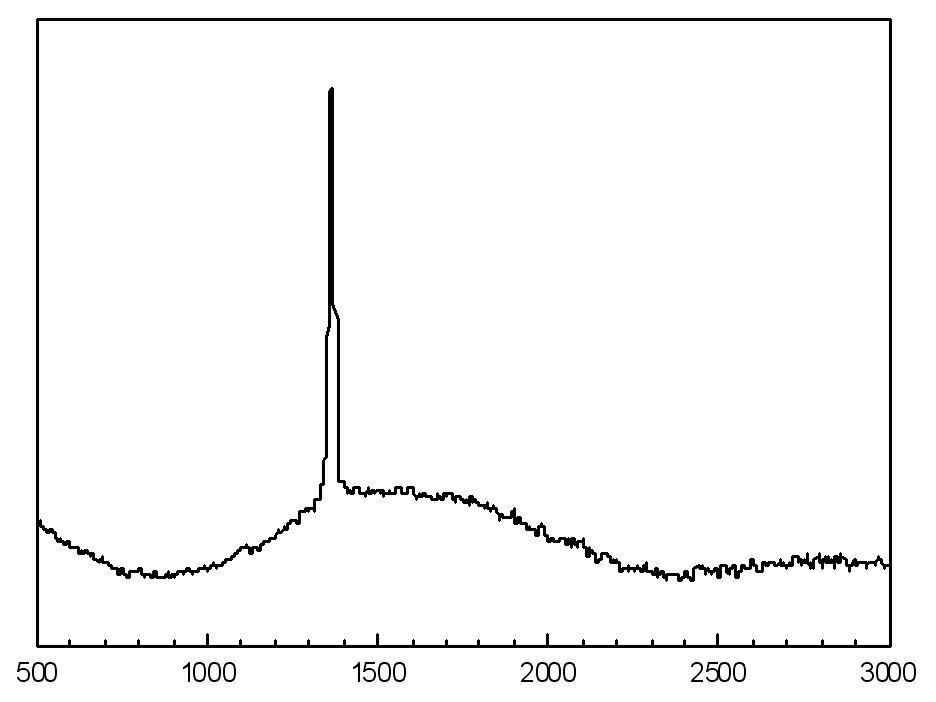

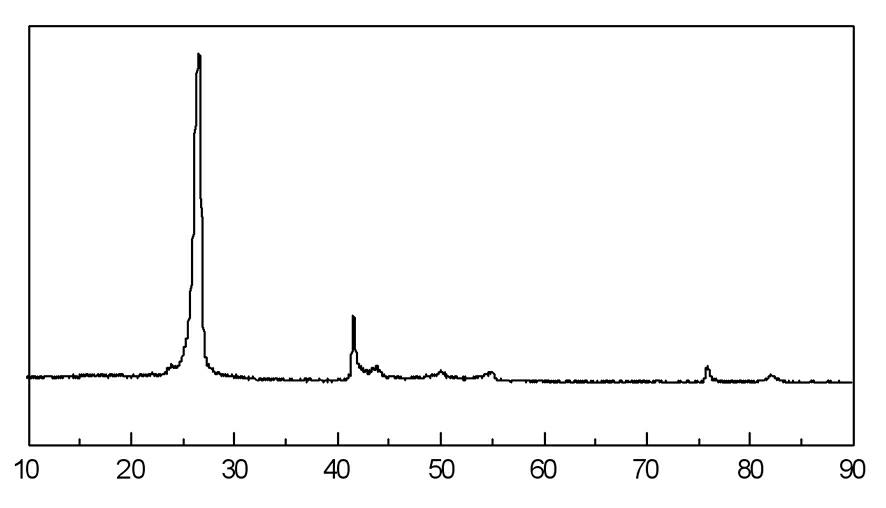

[0020] (1) Put the 2.5D T300 carbon fiber braid in the organic solvent acetone for ultrasonic cleaning to remove surface dust and other pollutants, and put it into the deposition furnace after drying; (2) Vacuum the deposition furnace, fill it with nitrogen, and repeat it three times , to replace the air in the deposition furnace; (3) evacuate the deposition furnace to 0.1 Pa, and raise the temperature to 1100 °C; (4) After the temperature stabilizes, introduce carrier gas nitrogen, the flow rate of carrier gas is 200 ml / min, and the system pressure is maintained at 1000Pa; the carrier gas brings borazine into the hearth of the deposition furnace by bubbling, and the holding temperature of the bubbling bottle is 0 ℃. After 2 hours, the boron nitride coating is formed; (5) After the deposition is completed, stop introducing the carrier gas, turn off the heating system, and cool down to room temperature with the furnace to obtain the hexagonal boron nitride coating deposited on t...

Embodiment 2

[0027] (1) Put the 2.5D quartz fiber braid in the organic solvent acetone for ultrasonic cleaning to remove surface dust and other pollutants, and put it into the deposition furnace after drying; (2) Same as step (2) of Example 1; (3) For The deposition furnace was evacuated to 0.5 Pa, and the temperature was raised to 800 °C; (4) After the temperature stabilized, the carrier gas nitrogen was introduced, the carrier gas flow rate was 100 ml / min, and the system pressure was maintained at 1100 Pa; The borazine is brought into the hearth of the deposition furnace, and the temperature of the bubbling bottle is -5 ℃. The boron nitride decomposed by borazine in the hearth of the deposition furnace is deposited on the surface of the fiber, and the deposition time is 2 hours to form a boron nitride coating; (5) After the deposition is over, stop introducing the carrier gas, turn off the heating system, and cool down to room temperature with the furnace, and the hexagonal boron nitride ...

Embodiment 3

[0030](1) Put the 2.5D silicon carbide fiber braid in the organic solvent acetone for ultrasonic cleaning to remove surface dust and other pollutants, and put it into the deposition furnace after drying; (2) Same as step (2) of Example 1; (3) Vacuum the deposition furnace to 0.2 Pa, and raise the temperature to 1100 °C; (4) After the temperature stabilizes, introduce carrier gas nitrogen, the carrier gas flow rate is 150 ml / min, and the system pressure is maintained at 800 Pa; The azine is brought into the hearth of the deposition furnace, and the holding temperature of the bubbling bottle is 5 °C. The boron nitride decomposed by boron azine in the hearth of the deposition furnace is deposited on the surface of the fiber, and the deposition time is 2 hours to form a boron nitride coating; (5) After the deposition is over, stop introducing the carrier gas, turn off the heating system, and cool down to room temperature with the furnace, and the hexagonal boron nitride coating dep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com