Boron nitride material and method of preparation thereof

A technology of boron nitride and amine borane, which is applied in the field of boron nitride materials and its preparation, can solve the problems of film deposition, lack of catalytic activity, epitaxial relationship growth mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

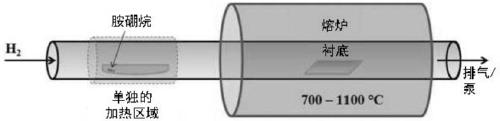

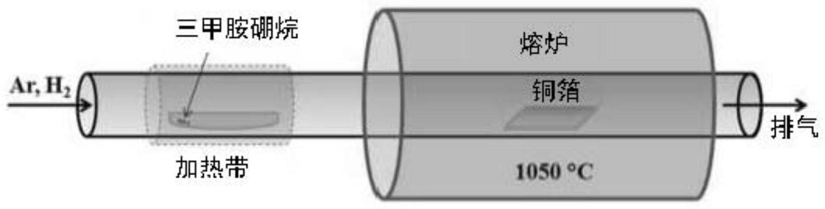

[0148] Example 1: Synthesis of h-BN and h-BCN membranes (Example 1)

[0149] Copper (Cu) foil (Alfa Asear, product number 13382, 25 micron thick) was used as a growth substrate for the h-BN and h-BCN films. Before growth, the Cu foil was first dipped in dilute nitric acid for a few seconds, and then washed with deionized water to remove the coating on the Cu surface. Then constant Ar / H at 200:20sccm 2 Load the Cu foil into a 1 inch quartz tube by flow down. The furnace was ramped up to 1050°C over 40 minutes and held constant for an additional 30 minutes to anneal the Cu and remove surface oxides.

[0150] After annealing, 10 mg of trimethylamine borane complex (Alfa Asear, Product No. L14994, 97%) placed in a ceramic boat placed outside the heating zone was heated at a specific temperature to start film growth. The growth time for monolayer h-BN single-crystal domains to become continuous films ranged from 5 to 20 min, while for h-BCN films, full coverage films were obta...

example 2

[0151] Example 2: Transfer process (embodiment 1)

[0152] Film transfer to SiO using an electrochemical delayering process 2 / Si and quartz substrates. First, the h-BN or h-BCN film grown on Cu was spin-coated with polymethyl methacrylate (PMMA) at 3000 rpm for 30 s. 1M NaOH was used as electrolyte. Pt foil was used as anode and the spin-coated sample was used as cathode. A constant voltage of 5 V was applied until the PMMA-coated sample was completely separated from Cu.

[0153] The samples were then washed several times in deionized water and transferred to the desired substrate. Bake the transferred samples at 50 °C until they are completely dry. Finally, PMMA was removed by immersing the samples in acetone for several hours.

example 3

[0154] Example 3: Characterization (Example 1)

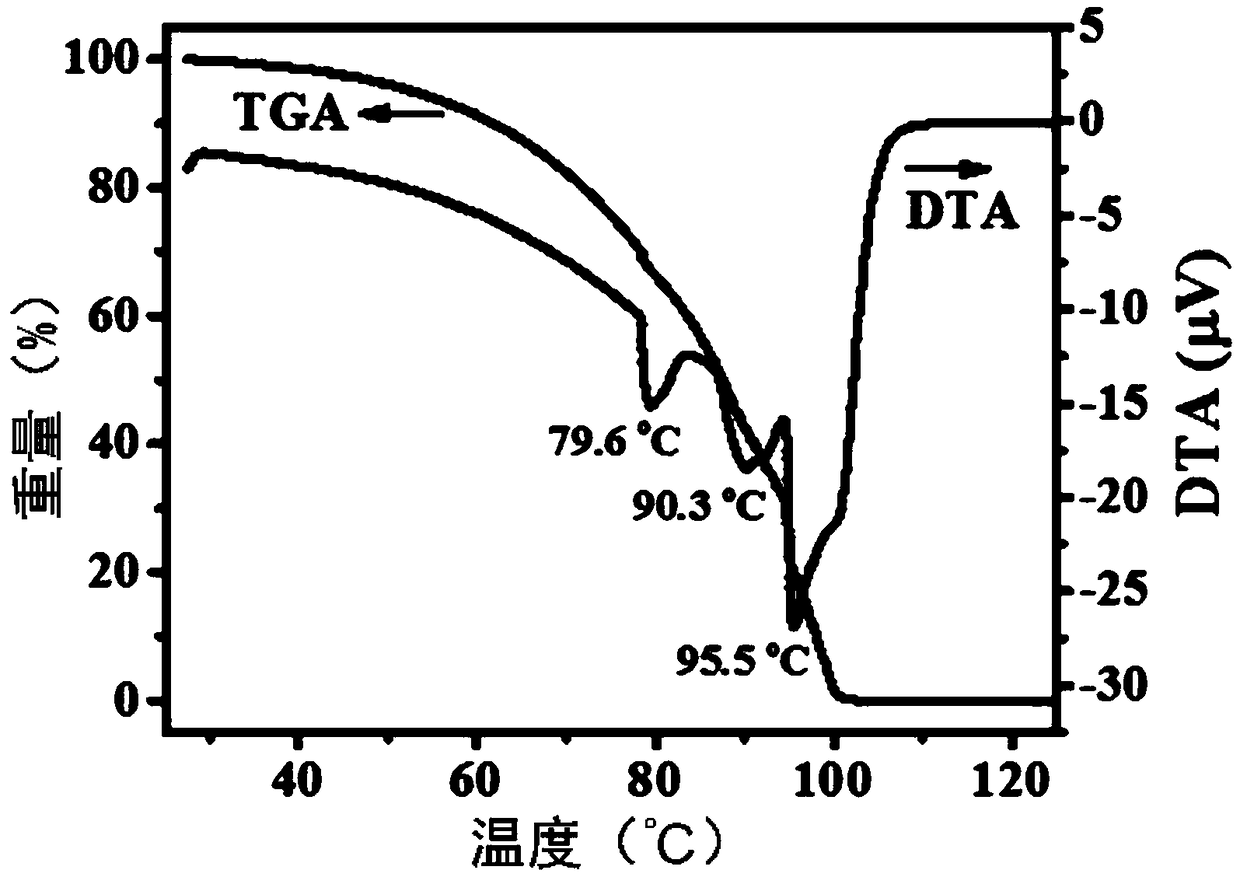

[0155] The thermal decomposition curve of TMAB was determined by thermogravimetric analysis (TGA, Shimadzu DTG-60H thermal analyzer). TGA measurements were performed in a constant nitrogen flow (100 mL / min) and heated from 25°C to 125°C at a ramp rate of 2°C / min.

[0156] Scanning electron microscopy (SEM, LEO1550Gemini) images were taken directly on h-BN and h-BCN films grown on Cu substrates.

[0157] Atomic force microscopy (AFM, Cypher scanning probe microscopy) detection using tapping mode to measure transfer to SiO 2 / Thicknesses of h-BN and h-BCN films on Si substrates.

[0158] Raman spectroscopic detection with a laser excitation wavelength of 532 nm (Witec) was performed at room temperature to measure the transfer to SiO 2 / Crystal structure of films on Si substrates.

[0159] at 4000- 1 -400cm- 1 Fourier-transform infrared spectroscopy (FT-IR, IRPrestige-21 spectrometer) detection was performed using h-BN films ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com